Why Chemical Exhaust Gas Treatment Matters

Chemical exhaust gases generated during laboratory reactions often contain corrosive, toxic, or environmentally harmful components. Without proper treatment, these gases can pose serious risks to laboratory personnel, equipment, and the surrounding environment. As laboratory processes become more complex, effective laboratory gas scrubber systems have become essential for chemical exhaust gas treatment and overall laboratory safety.

Laboratories face multiple challenges when handling chemical exhaust gases, making efficient treatment a complex task. These challenges include:

- Fluctuating gas flow rates: Laboratory reactions can produce variable volumes of exhaust gases depending on reaction scale, duration, and temperature, making it difficult to maintain consistent absorption efficiency.

- Varying chemical compositions: Exhaust streams often contain mixtures of acidic, basic, and reactive vapors, as well as aerosols or fine particles. This chemical variability requires a flexible laboratory gas scrubber system capable of adapting to different gas compositions without compromising safety or efficiency.

- High temperatures: Many laboratory processes generate hot exhaust gases that can damage standard ventilation systems or reduce the performance of conventional scrubbers. Specialized pilot-scale gas scrubbers with cooling and temperature control are necessary to handle high-temperature emissions safely.

- Limited installation space: Laboratory environments often have confined spaces, making it challenging to install large or complex exhaust treatment systems. Compact and modular gas scrubber systems designed for laboratory or pilot-scale use can fit in tight spaces while maintaining high absorption efficiency.

Traditional ventilation alone is often insufficient, particularly when dealing with corrosive acid gases, volatile organic compounds, or reactive vapors. A dedicated pilot-scale gas scrubber ensures reliable chemical exhaust gas treatment, compliance with safety and environmental regulations, and protection of both personnel and sensitive laboratory equipment.

By addressing these challenges with a well-designed laboratory gas scrubber system, laboratories can maintain safe working conditions, optimize gas absorption performance, and achieve consistent results in both research and pilot-scale chemical processes.

How Laboratory Gas Scrubber Systems Work

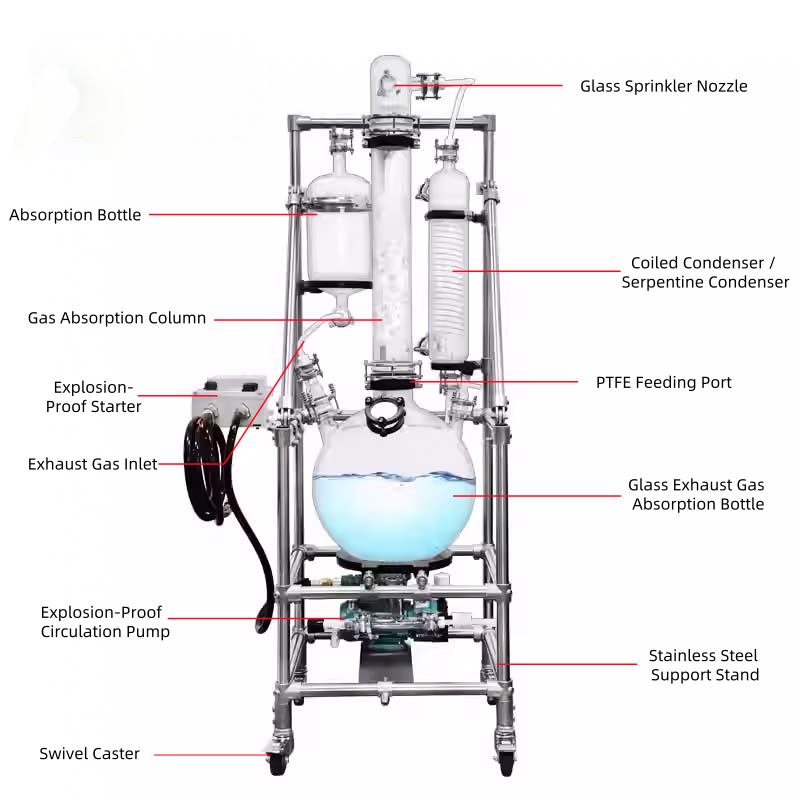

The ERL Gas Scrubber uses a circulation pump to move the absorption liquid from a round-bottom flask through a condenser into a spray nozzle. The liquid sprays from the top of the absorption tower, passing through the packing material and returning to the absorption tank. This ensures thorough gas-liquid contact, allowing the laboratory gas scrubber to efficiently capture harmful gases and aerosols.

For high-temperature exhaust gases, a condenser can cool the absorption liquid. The system can also be combined with active absorption methods, such as using nitrogen as a carrier gas or applying a vacuum to guide the exhaust through the scrubber, optimizing chemical exhaust gas treatment in laboratory and pilot-scale environments.

Applications of Gas Scrubber Systems in Laboratory and Pilot-Scale Processes

Laboratory gas scrubbers are commonly used in:

- Pharmaceutical synthesis

- Fine chemical research

- Material science experiments

- Pilot-scale reaction testing

By combining wet gas scrubbing with cooling or vacuum systems, laboratories can achieve stable, controllable, and efficient exhaust gas treatment. The ERL Gas Scrubber is compatible with:

- Fume hoods for localized gas collection

- Single-layer and double-layer glass reactors

- Laboratory vacuum systems

- Circulating cooling systems

This combination ensures safe, high-efficiency operation in both laboratory and pilot-scale chemical processes.

Advantages of the ERL Laboratory Gas Scrubber

The ERL Gas Scrubbing System offers:

- Explosion-proof safety for hazardous gas handling

- Durable 304 stainless steel construction with PTFE gaskets

- Customizable packing materials (glass, stainless steel, or tailored options)

- Modular and compact design suitable for limited lab space

- High absorption efficiency for chemical exhaust gas treatment

Whether for dry cooling of exhaust gases, gas-liquid reactions, or laboratory safety management, this laboratory and pilot-scale gas scrubber is a reliable and indispensable solution for modern laboratories and small-scale production facilities.

Solution

The ERL Laboratory Gas Scrubber System provides safe and efficient chemical exhaust gas treatment for both laboratory and pilot-scale processes. With customizable options, it supports multi-stage scrubbing setups to maximize gas absorption efficiency and ensure compliance with safety and environmental standards. Learn more about our laboratory gas scrubber system and explore the complete product specifications.