One-stop service for laboratory extraction instruments

Qualitative · Quantitative · Analytical chemistry · Organic chemistry Inorganic chemistry · Physical chemistry · biochemistry · Environmental chemistry · Industrial chemistry · Teaching experiment

Competitive Price

The Best Price for the Best Products.

5 Stars Reviews

High Praise from Customers.

Reliable & Fast Support

Our Tech and Team Are Phenomenal.

Fast & Safe Shippping

Ship Every Package Speedily with Care.

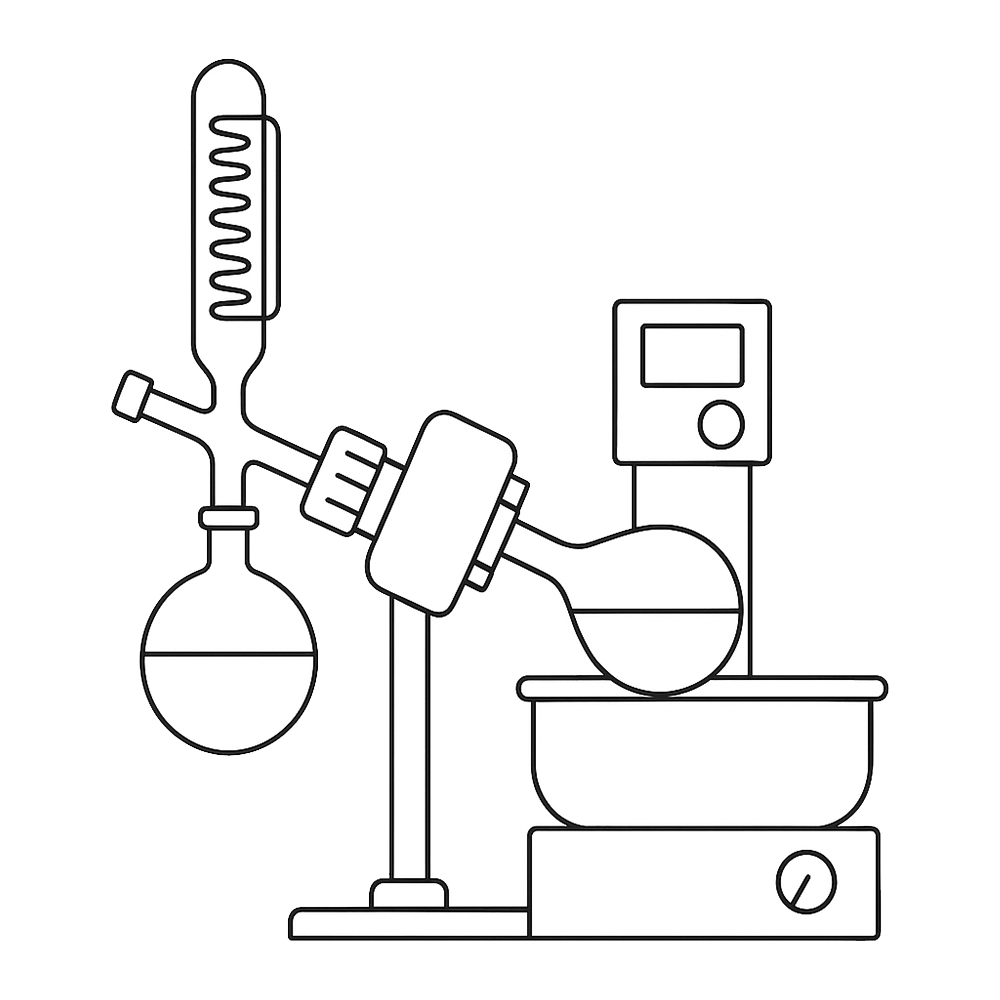

Main Categories

Hot Products

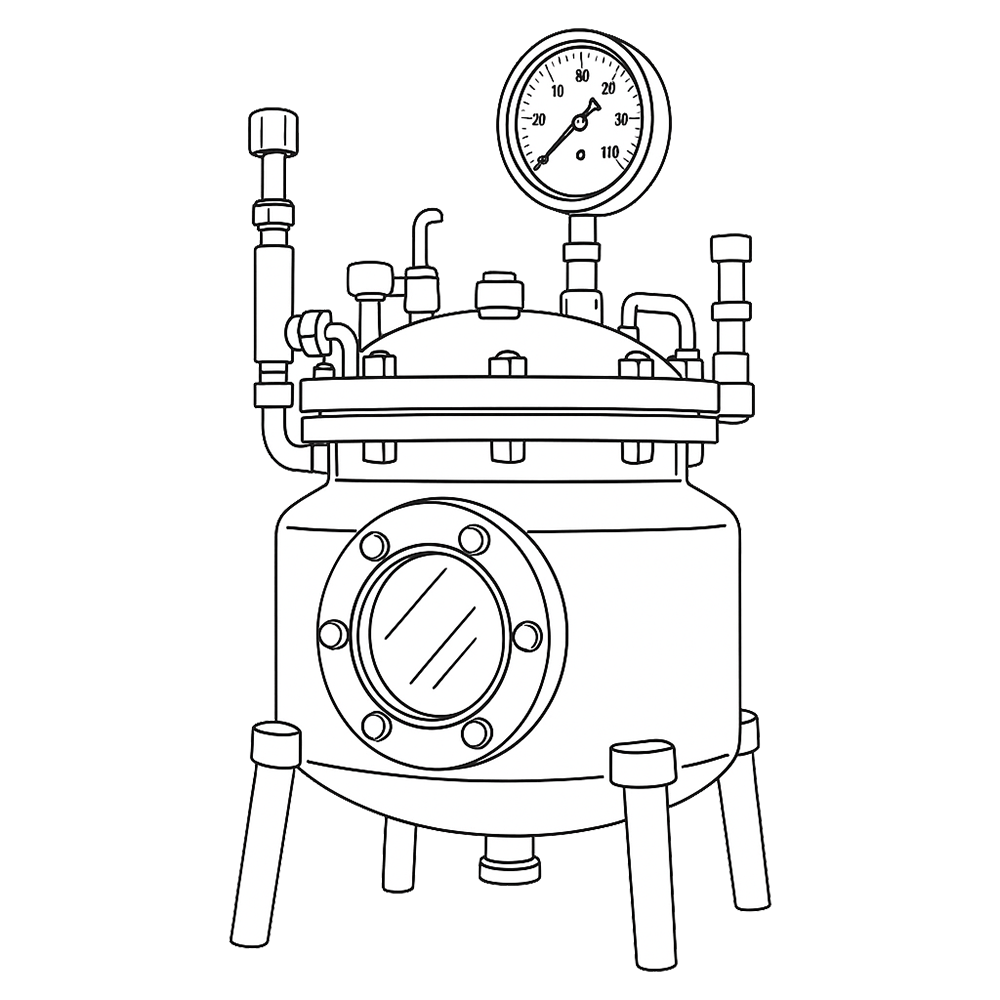

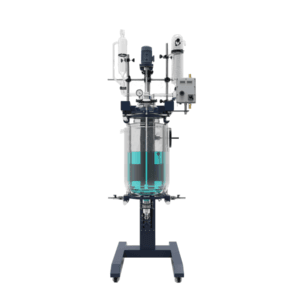

5L–50L Jacketed Stainless Steel Crystallization Filtration Reactor

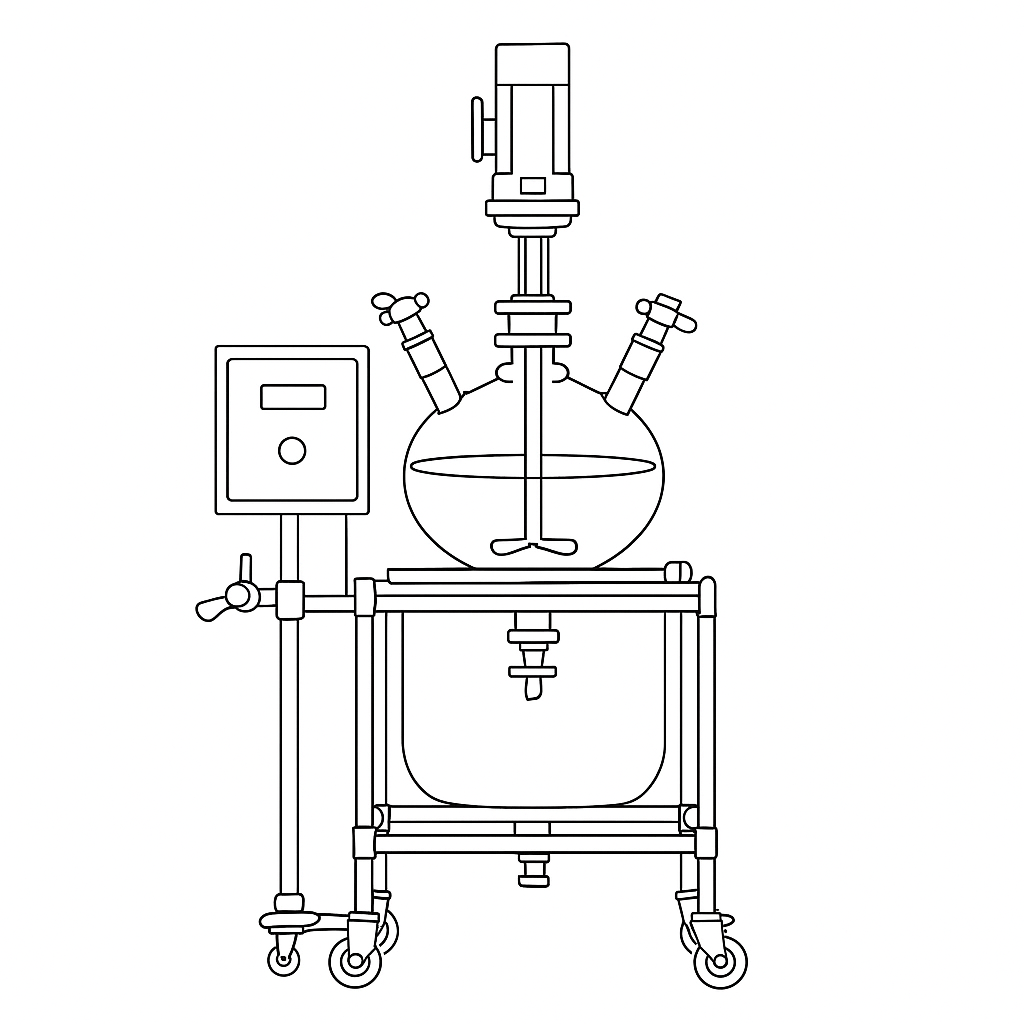

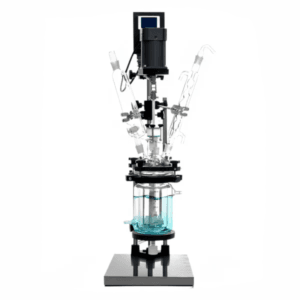

Jacketed Crystallization Filtration Reactor2L–50L Jacketed Glass Crystallization Filtration Reactor

Jacketed Crystallization Filtration Reactor

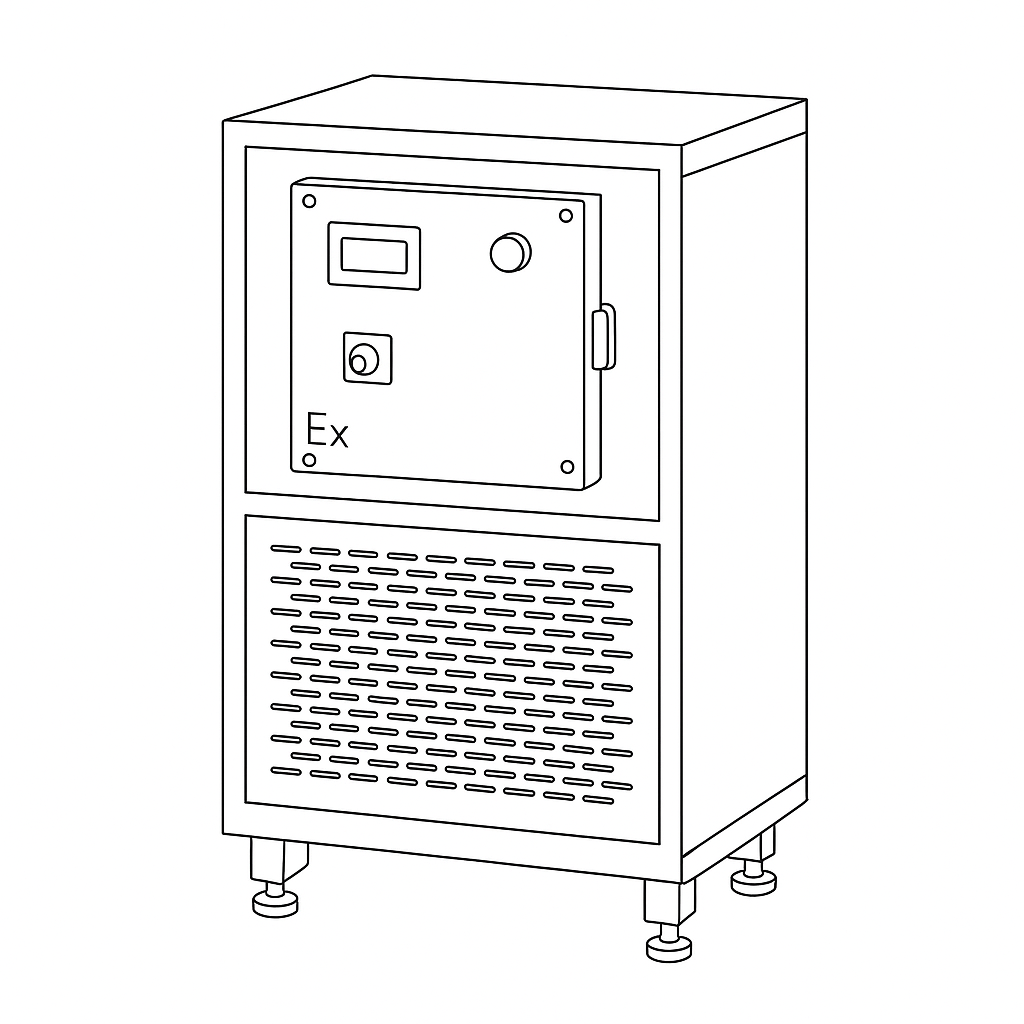

Special Products

Cutting-edge News

Technical Support

Publish technical support and solutions to help users better use and maintain chemical instruments.

Academic Promotion

Investing in knowledge paves the way for future breakthroughs. Equilrxnlab simplifies equipping your labs for cutting-edge research!

Industry News

Provides the latest developments and market trends in the chemical instrument industry.

Company News

Promote the company's internal news, activities and development direction, so that users know the latest developments of the company.

Company Introduction

Industries served by EquilRxnLab

EquilRxnLab provides process, pilot plant, and laboratory equipment for separation, reaction, filtration, and other operations across a wide range of industries — including high-value fine and specialty chemicals, pharmaceuticals, edible and essential oils, food, flavors, polymers, electronics, lubricants, waxes, vegetable extracts, cosmetics, and bio-based materials.

Who we are

We Create Solutions that Work —

At EquilRxnLab, we unite a team of experienced engineers, chemists, and technical specialists driven by innovation and precision. From process design to equipment implementation, we deliver practical, efficient, and dependable solutions to complex challenges. Our technical expertise and hands-on experience empower clients to transform ideas into successful outcomes across every stage of research and production.

FAQ

All EquilRxnLab products come with detailed user manuals. These manuals include installation steps, operating instructions, safety precautions, and maintenance recommendations. They not only guide you on how to operate the equipment correctly but also provide detailed technical specifications and troubleshooting guidelines.

For more complex equipment, EquilRxnLab also offers video tutorials and remote technical support to ensure easy operation. If you require additional technical assistance or digital versions of the manuals, please feel free to contact our customer service team.

EquilRxnLab’s chemical instruments strictly comply with various international standards and certifications to ensure product quality, safety, and to meet the needs of global customers. Key certifications and standards include:

CE Certification (Conformité Européenne)

Most of EquilRxnLab’s equipment has obtained CE certification, confirming compliance with the European Economic Area (EEA) safety, health, and environmental protection requirements, and allowing legal sales in European markets.

RoHS Directive (Restriction of Hazardous Substances)

EquilRxnLab’s products comply with the RoHS directive, which restricts the use of certain hazardous substances such as lead and mercury, ensuring they meet EU environmental standards.

ISO 9001: Quality Management System Certification

EquilRxnLab’s manufacturing processes are certified under ISO 9001, ensuring that every stage—from design to production—follows strict quality management protocols, providing customers with consistent and reliable products.

UL Certification (Underwriters Laboratories)

For the U.S. market, some of EquilRxnLab’s products are UL certified, indicating compliance with U.S. electrical safety standards and offering enhanced safety assurance to users.

FCC Certification (Federal Communications Commission)

EquilRxnLab’s electronic devices comply with FCC standards for electromagnetic interference, ensuring that products sold in the U.S. are safe and compliant.

FDA Registration (Food and Drug Administration)

For laboratory or medical-related equipment, certain EquilRxnLab products are FDA registered, guaranteeing compliance with U.S. medical device standards.

These certifications enable EquilRxnLab to deliver high-quality chemical instruments to customers in Europe and the United States, ensuring our products are safe, reliable, and compliant with all local regulations. For further details or inquiries, please feel free to contact our customer service team.

If you need to modify or cancel your order, please contact our customer service team at EquilRxnLab as soon as possible. Orders can be modified or canceled before shipment. The process is as follows:

Modify Order: Please provide your order number and the specific details that need to be changed (such as product model, quantity, shipping address, etc.), and we will expedite the processing of your request upon confirmation.

Cancel Order: Similarly, provide your order number, and once we confirm the order status, we will assist you in canceling the order. If the order has already been shipped, cancellation may involve a return process.

Please note that modification or cancellation requests should be submitted as soon as possible. Orders that have been shipped cannot be directly modified or canceled and must be returned in accordance with policy. For further assistance, feel free to contact our customer service team.

Yes, EquilRxnLab offers international shipping, and we provide free shipping for orders that meet specific criteria. No matter where you are in the world, we ensure your order is delivered safely and on time.

Here are the details of our free shipping policy:

- Order Amount Requirement: If your order exceeds [specific amount], you will automatically qualify for free international shipping.

- Shipping Method: Standard shipping is eligible for free shipping. If you require expedited shipping, additional fees may apply.

- Note: Some remote areas may not qualify for free shipping, but if applicable, we will notify you during checkout.

At checkout, the free shipping policy will be applied automatically. If you have any questions about free shipping or other delivery options, feel free to contact our customer service team for assistance.

Once your order is confirmed and payment is received, EquilRxnLab typically processes and ships the order within 2-3 business days. If the product you ordered requires customization or is out of stock, the processing time may be slightly longer. We will notify you of the estimated shipping time after your order is confirmed.

After your order is shipped, we will provide you with a tracking number via email so you can track the shipment status at any time. If you have any questions regarding the shipping time, feel free to contact our customer service team.

If you have any complaints or concerns, EquilRxnLab takes them very seriously and aims to resolve the issue as quickly as possible. You can submit a complaint through the following methods:

- Email: Please send a description of your complaint to [complaints email address], including your order number or any relevant information. We will respond within 1-2 business days to address your concerns in detail.

- Phone Support: You can call our customer service hotline at [customer service phone number], and our team will assist you immediately and record your complaint.

- Live Chat: Use the live chat feature on our website to communicate with a customer support representative in real time. Your complaint will be forwarded to the appropriate department for prompt handling.

- Feedback Form: Visit the feedback page on our website, fill in the necessary details, and submit the form. We will contact you to resolve your issue.

We are committed to ensuring a positive customer experience and will address your complaint in a timely manner. If you have any other questions or needs, feel free to contact our customer service team.

If you need to contact customer support, EquilRxnLab offers several convenient ways to assist you with any issues:

- Email: You can email our support team at [support email address], and we will respond to your inquiry within 1-2 business days.

- Phone Support: You can call our customer service hotline at [customer service phone number], and our support team will assist you during business hours.

- Live Chat: Visit our website and use the live chat feature to communicate with a customer support representative in real time.

- Help Center: Our website also provides a detailed Help Center containing FAQs and guides, where you can find solutions on your own.

No matter the issue, our customer support team at EquilRxnLab is committed to providing the help you need and resolving your concerns in a timely manner. If you have any questions, feel free to contact our customer service team.

We value the feedback of every customer and are committed to providing high-quality service. If you encounter any issues while using our products or services, please submit your complaint.