Introduction to Single Glass Reactor Design

In chemical engineering and laboratory environments, the Single Glass Reactor design is integral to a variety of processes, from synthesis to distillation. This design ensures controlled reactions, maintaining high levels of precision and efficiency. The Single Glass Reactor design has evolved over the years, offering a versatile tool for both small-scale and large-scale applications.

The core function of the Single Glass Reactor is to provide a controlled environment where chemical reactions can take place under precise conditions. Its transparent glass construction allows researchers to observe the reaction process in real-time, ensuring greater accuracy and safety. This versatility makes the Single Glass Reactor design a fundamental part of many laboratory settings.

Key Features of Single Glass Reactor Design

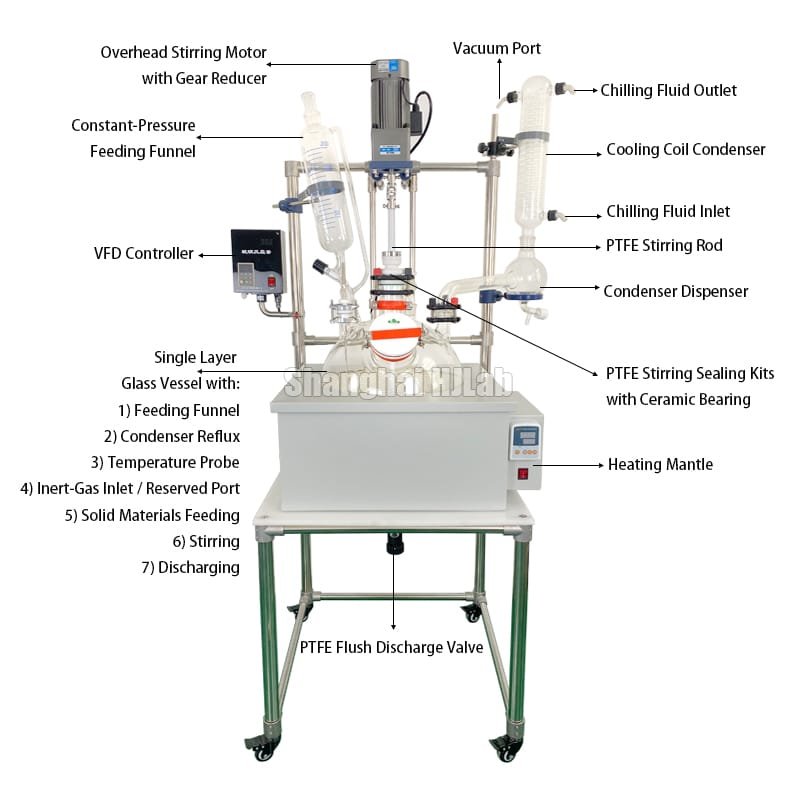

The single glass reactor design offers a versatile and efficient platform for a variety of applications. One of the most notable aspects is its simplicity. Unlike more complex reactors, a single glass reactor typically consists of a vessel, a stirring mechanism, a heating/cooling jacket, and a condenser. These elements work in harmony to ensure precise control of the reaction environment.

- Glass Vessel

The transparent glass allows operators to monitor the reaction process visually, providing invaluable insight into the chemical dynamics within. The clarity of the glass is particularly important when working with compounds that require careful observation or when reacting in a controlled environment, such as for pharmaceuticals or fine chemicals. - Heating and Cooling Jackets

Many single glass reactor designs feature double-walled construction, with an inner chamber for the reaction and an outer jacket for heating or cooling. This dual setup allows for precise temperature control, critical for ensuring consistent reaction conditions. Heating is often achieved via circulating water or oil, while cooling can be facilitated by chilled liquids or gases. - Efficient Stirring Mechanism

The stirring mechanism is designed to ensure thorough mixing of the contents, which is vital for reactions where uniformity is key. Different types of stirrers, such as magnetic or mechanical, can be used depending on the nature of the materials being processed. A robust stirring system is essential to avoid settling of solids or to ensure proper dissolution of substances during chemical processes. - Vacuum and Pressure Control

Many single glass reactor designs offer integrated vacuum and pressure systems, allowing for the operation of reactions under a controlled atmosphere. This capability is especially useful for processes that require reduced pressure or a controlled inert environment, such as in the production of certain pharmaceuticals or the synthesis of high-value chemicals.

Advantages of Single Glass Reactor Design

The single glass reactor design offers numerous advantages that make it a popular choice in laboratories and industrial settings.

- Cost-Effective

Compared to multi-chamber or more complex reactors, the single glass reactor design is often more affordable while still offering excellent functionality. This cost-effectiveness makes it an attractive choice for many research institutions and small to mid-scale production facilities. - Versatility in Applications

The single glass reactor design is versatile and can be used for a variety of chemical processes, including distillation, synthesis, and extraction. Its ability to handle different materials and reactions makes it a preferred option in labs and industries where diverse chemical processes are conducted. - Space Efficiency

With a compact design, single glass reactors take up less space in the lab compared to larger, more complex systems. This space efficiency is especially important for labs with limited room or for operations that require multiple reactors to run simultaneously. - Ease of Maintenance

The simplicity of the single glass reactor design makes it easier to maintain and troubleshoot. The fewer components involved, the less there is to go wrong. Routine maintenance typically involves checking for leaks, ensuring proper cleaning, and inspecting the seals, making it relatively straightforward to keep the reactor in optimal working condition.

Applications of Single Glass Reactors

- Chemical Synthesis

One of the primary uses of the single glass reactor design is in chemical synthesis. Researchers often use glass reactors for reactions that require precise temperature and pressure control, such as the synthesis of fine chemicals, pharmaceutical compounds, and specialty polymers. The transparency of the glass allows for easy monitoring, making it a crucial tool in synthetic chemistry. - Pharmaceutical Manufacturing

In pharmaceutical manufacturing, a single glass reactor design is used for tasks such as drug formulation and testing. It allows for the careful mixing of ingredients, ensuring uniformity and accuracy in product development. Additionally, the reactor’s ability to maintain a sterile, controlled environment makes it suitable for sensitive compounds and formulations. - Pilot-Scale Production

For pilot-scale production, the single glass reactor design offers a reliable platform to scale up chemical reactions from the laboratory to a larger scale. The same control mechanisms used in the laboratory reactor can be employed in the pilot reactor, providing consistency and reliability as the process moves toward industrialization.

Considerations When Selecting a Single Glass Reactor

When choosing a single glass reactor design, it is important to consider the following factors:

- Volume and Capacity

The capacity of the reactor should match the scale of your operations. For small-scale experiments, a single glass reactor design with a smaller volume may suffice, but for larger-scale production, a larger model may be required. Models like the AKDF-1L single-layer glass reactor offered by EquilRxnLab provide options for various needs, whether for research or production purposes. - Material Compatibility

Ensure that the materials used in the reactor are compatible with the chemicals you plan to process. Glass reactors are usually made from high-quality borosilicate glass, which is resistant to thermal and chemical stress. However, always check that the seals and other components are suited for your specific applications. - Temperature and Pressure Requirements

Different processes have varying temperature and pressure requirements. Ensure that the single glass reactor design you select is capable of withstanding these conditions. Some models come with additional features like a double-walled design for improved temperature control or integrated vacuum systems for pressure management.

Where to Find the Best Single Glass Reactor Designs

For those looking for a high-quality single glass reactor design, EquilRxnLab offers a wide range of reliable and durable options. The AKDF-1L single-layer glass reactor is perfect for small-scale reactions and research applications. To explore this model, visit here.

For more updates, tutorials, and maintenance tips, be sure to follow EquilRxnLab on YouTube, Instagram, and Facebook. You can also explore our full product catalog on Flbook.

For inquiries, feel free to contact us directly.