The production of fine chemicals, such as pharmaceuticals, agrochemicals, and specialty materials, requires highly controlled reaction environments. A Liftable Glass Reactor for Fine Chemicals is an advanced system designed to facilitate safe, reproducible, and efficient chemical processing.

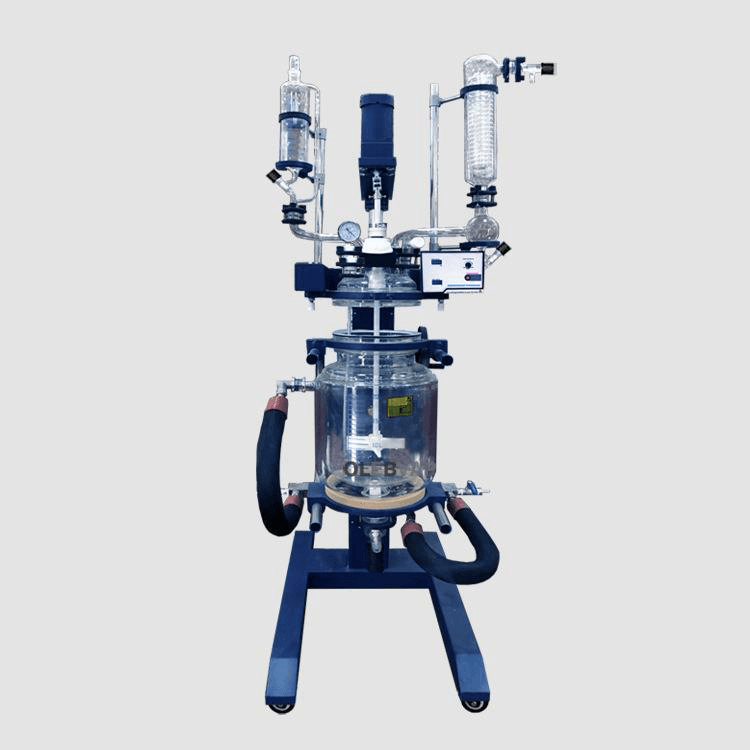

EquilRxnLab’s 50L Double-Layer Glass Liftable Reactor provides exceptional control over reaction parameters, making it an essential instrument for researchers and manufacturers.

Key Features of a Liftable Glass Reactor for Fine Chemicals

1. Adjustable Lift Mechanism for Safe and Efficient Handling

One of the primary advantages of a Liftable Glass Reactor for Fine Chemicals is its electric lifting system, which enables:

- Easy access to reaction vessels for sampling, cleaning, and maintenance

- Enhanced safety by reducing direct contact with reactive chemicals

- Streamlined operations, eliminating the need for manual adjustments

The 50L Double-Layer Glass Liftable Reactor ensures precision lifting and positioning, improving overall efficiency.

2. Double-Layer Glass for Temperature Stability

Fine chemical synthesis often requires precise temperature control. The double-layer glass design provides:

- Effective thermal insulation, preventing unwanted heat loss

- Uniform heating and cooling, ensuring stable reaction conditions

- Protection against sudden temperature changes, which is critical for sensitive reactions

This high-quality borosilicate glass construction guarantees chemical resistance and durability, making the reactor ideal for fine chemical applications.

3. Optimized Mixing for Homogeneous Reactions

Efficient mixing is crucial in fine chemical synthesis to ensure complete reactant interaction. The rotational capabilities of a Liftable Glass Reactor for Fine Chemicals offer:

- Consistent agitation, preventing phase separation

- Even temperature distribution, improving reaction uniformity

- Reduced particle aggregation, optimizing product yield

The 50L Double-Layer Glass Liftable Reactor integrates high-performance stirring mechanisms for reliable and repeatable results.

Advantages of Using a Liftable Glass Reactor for Fine Chemicals

By incorporating liftable reactors into chemical synthesis processes, laboratories and industries benefit from:

✅ Enhanced Safety – Minimized exposure to hazardous chemicals

✅ Improved Process Control – Precise adjustments to temperature, pressure, and mixing parameters

✅ Scalability – Suitable for small-scale research and large-scale production

✅ Energy Efficiency – Optimized heating and cooling mechanisms for reduced energy consumption

EquilRxnLab’s reactors are engineered for high-performance applications, making them a preferred choice in fine chemical manufacturing.

Applications of the Liftable Glass Reactor for Fine Chemicals

The versatility and precision of liftable glass reactors make them indispensable in various chemical industries, including:

- Pharmaceutical Synthesis – Facilitates the development of high-purity active pharmaceutical ingredients (APIs)

- Agrochemical Production – Ensures controlled synthesis of pesticides and fertilizers

- Polymer Chemistry – Enables precise polymerization and material development

- Dye and Pigment Manufacturing – Provides stable reaction conditions for high-quality colorants

With its advanced automation and precision control, the 50L Double-Layer Glass Liftable Reactor is a vital asset in fine chemical production.

Selecting the Right Liftable Glass Reactor for Fine Chemicals

When choosing a reactor, it is essential to consider:

- Volume and Scalability – Ensuring the reactor meets production needs

- Material Durability – High-quality borosilicate glass and corrosion-resistant components

- Automation Features – Electric lifting and advanced mixing mechanisms

- Regulatory Compliance – Adhering to GMP and industry safety standards

For a comprehensive selection of laboratory reactors, explore the EquilRxnLab product catalog.

Why Choose EquilRxnLab’s Liftable Glass Reactor for Fine Chemicals?

EquilRxnLab is a trusted provider of laboratory and industrial reactors, offering:

- Innovative Design – Cutting-edge liftable and rotating reactor technology

- Superior Quality – Durable and high-precision engineering

- Technical Support – Expert guidance and comprehensive after-sales services

For custom solutions and expert recommendations, reach out to EquilRxnLab.

Stay Updated on the Latest Advancements

Follow EquilRxnLab for insights into cutting-edge reactor technology and fine chemical processing:

Advancing Fine Chemical Synthesis with Liftable Reactors

A Liftable Glass Reactor for Fine Chemicals is a critical component in precision-driven chemical synthesis, offering advanced temperature control, efficient mixing, and user-friendly operation. The 50L Double-Layer Glass Liftable Reactor from EquilRxnLab is designed to meet the highest standards in chemical research and production, ensuring reproducibility and efficiency in every reaction.