100L jacketed glass reactor serves as a reliable solution for medium-scale laboratory experiments and pilot-scale production. Featuring high transparency, excellent corrosion resistance, and precise temperature control, it allows researchers and engineers to monitor reactions in real-time while maintaining optimal conditions.

Widely applied in pharmaceuticals, chemical synthesis, new materials research, as well as food and dye processing, the 100L jacketed glass reactor ensures safety and efficiency, making it an indispensable tool for both laboratories and industrial facilities.

This article provides a detailed analysis of the 100L jacketed glass reactor, covering key aspects including its materials, capacity and dimensions, temperature control and jacket system, pressure performance, stirring system, corrosion resistance and durability, practical applications, and buying guidance. Each section is designed to help researchers and engineers fully understand the reactor’s capabilities and make informed decisions for their experiments or pilot-scale production.

Overview

The 100L jacketed glass reactor features a high borosilicate glass inner vessel, resistant to acids, alkalis, and most organic solvents, ensuring safe and reliable reaction processes.

The reactor is equipped with a stainless steel frame and bottom swivel casters for easy mobility and installation. In special environments, the frame can be coated with PTFE to enhance corrosion resistance.

The jacket system supports circulating water, oil bath, or electric heating, enabling rapid heating and uniform cooling to maintain precise reaction temperatures. The inner vessel is designed with a stirring shaft and impeller, ensuring uniform mixing throughout the entire volume. An optional ultrasonic probe can be installed for enhanced mixing efficiency.

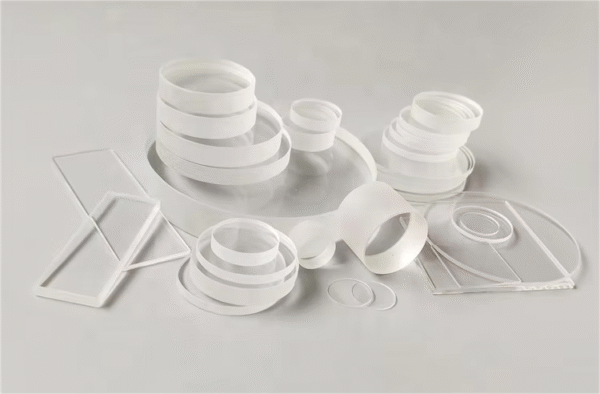

Corrosion-resistant sealing components, combined with safety valves and pressure monitoring devices, guarantee safe operation under atmospheric or negative pressure conditions, providing reliable support for both laboratory experiments and pilot-scale production.

Material Comparison

100L jacketed glass reactor can be constructed with borosilicate glass or quartz glass, offering excellent resistance to acids, bases, and most organic solvents. Its high transparency allows direct observation of the reaction process while ensuring precise control. The entire glass assembly can be supported with a stainless steel frame, providing additional safety and protection.

Borosilicate Glass

- Thermal Resistance: Low thermal expansion (~3.3 × 10⁻⁶/K), able to withstand rapid heating or cooling without cracking, suitable for high-temperature or temperature-cycling reactions.

- Chemical Resistance: Resistant to acids, bases, and most organic solvents, ensuring long-term durability without contamination.

- Transparency: High transparency allows direct observation of reactions and precise process control.

- Mechanical Strength: Thermally treated glass maintains stable strength, compatible with the jacket and frame to ensure safe operation. A stainless steel frame provides additional protection for the entire glass assembly.

- Applications: Commonly used in chemical, pharmaceutical, food industries, and pilot-scale reactors, balancing corrosion resistance and cost-effectiveness.

Quartz Glass / Fused Silica

- High-Temperature Resistance: Can withstand extremely high temperatures (up to 1100–1200℃), suitable for ultra-high temperature chemical reactions.

- Chemical Resistance: Extremely resistant to most acids and high-temperature solvents, though sensitive to strong alkalis.

- Transparency: Higher optical transmittance, ideal for photochemical or optical reactions.

- Mechanical Strength: Brittle and low impact resistance; careful handling is required. A stainless steel frame can provide safety and protection for the glass assembly.

- Applications: Often used in high-temperature reactions, photochemistry, or high-purity chemical processing; more expensive and less common for pilot-scale reactors.

Capacity & Dimensions

The 100L jacketed glass reactor has a nominal volume of 100 liters, with an effective working capacity of approximately 65–70 liters. This design provides sufficient space for stirring and material expansion, helping to maintain uniform reactions and safe operation. The jacket capacity is 22 liters, suitable for circulating water, oil bath, or cooling fluids. When selecting an external temperature control unit, both the jacket volume and target temperature range should be considered.

The standard overall dimensions are approximately 780mm × 730mm × 2500mm, with an inner vessel diameter of about 290mm and an outer vessel diameter of 500mm. The stirring shaft diameter is 20mm, and the rotational speed can be adjusted from 0 to 350 rpm. Proper dimensional design ensures uniform circulation of the jacket medium for efficient heating or cooling while providing stable and effective mixing.

Temperature Range and Temperature Control System Analysis

The operating temperature range of a 100L jacketed glass reactor typically spans from -120°C to 300°C, meeting a wide variety of process requirements from low-temperature synthesis to high-temperature reactions. This wide temperature range makes it suitable for both laboratory research and pilot-scale production.

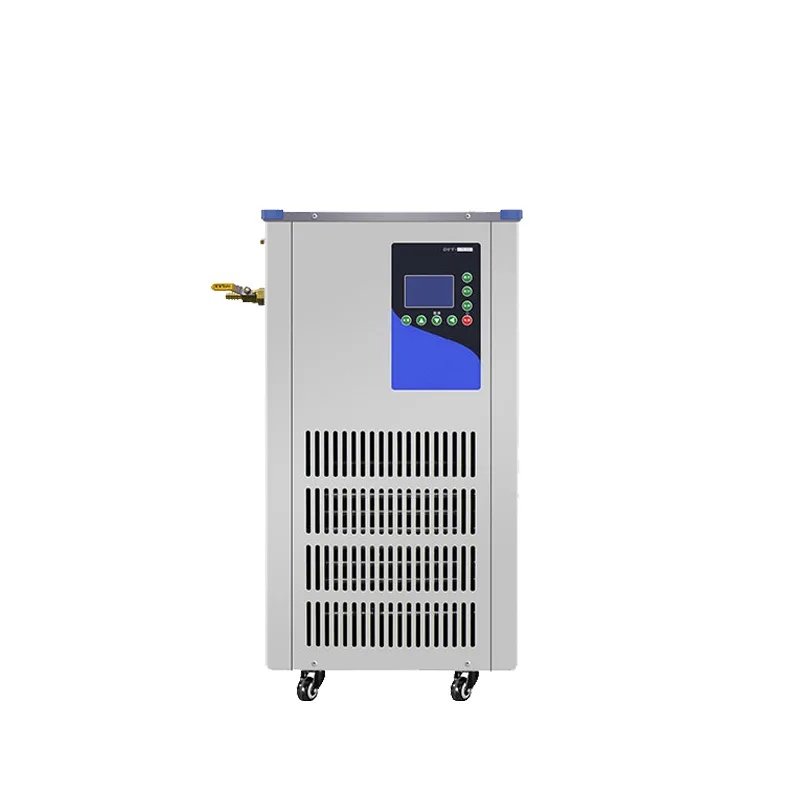

The jacketed structure is the core component for precise temperature control. Depending on process requirements, the jacket space can be filled with different heat transfer media. For low-temperature applications, the reactor is commonly paired with a low-temperature circulating chiller to achieve stable cooling performance. For heating applications, hot water or thermal oil can be used in combination with a high-temperature circulating oil bath. It should be noted that when water is used as the heating medium, the controllable temperature is generally limited to 99°C. For higher operating temperatures, thermal oil should be selected as the heat transfer medium.

By connecting to an external low-temperature chiller or high-temperature oil bath system, the jacketed glass reactor can achieve rapid heating or stable cooling. In addition, a high–low temperature integrated circulator can be selected to meet processes that require both heating and cooling within the same operation. Uniform circulation of the jacket medium around the vessel helps minimize localized overheating and temperature gradients, thereby improving process controllability and repeatability.

In practical applications, temperature accuracy depends not only on the jacket design but also on the power of the external temperature control unit, circulation flow rate, and placement of temperature sensors. By properly matching the capacity of the temperature control system and installing temperature probes inside the reactor, real-time monitoring and precise control of the reaction temperature can be achieved, ensuring stable and safe operation.

Pressure Performance Analysis

The pressure resistance of glass reactors is generally limited, with an allowable operating pressure typically between 0.05 MPa and 0.1 MPa, and a negative pressure of up to -0.1 MPa. The exact pressure limits depend on the vessel design, glass thickness, and sealing method. Within this range, the jacketed glass reactor can operate safely and stably under atmospheric pressure, slight positive pressure, or vacuum conditions, meeting the needs of most laboratory and pilot-scale processes.

In practical use, it is essential to strictly adhere to the reactor’s rated pressure range to prevent structural damage or safety hazards caused by excessive internal pressure. For processes requiring higher reaction pressures, stainless steel high-pressure reactors or other dedicated high-pressure equipment should be considered to ensure process safety and long-term reliable operation.

Stirring System and Selection for 100L Jacketed Glass Reactor

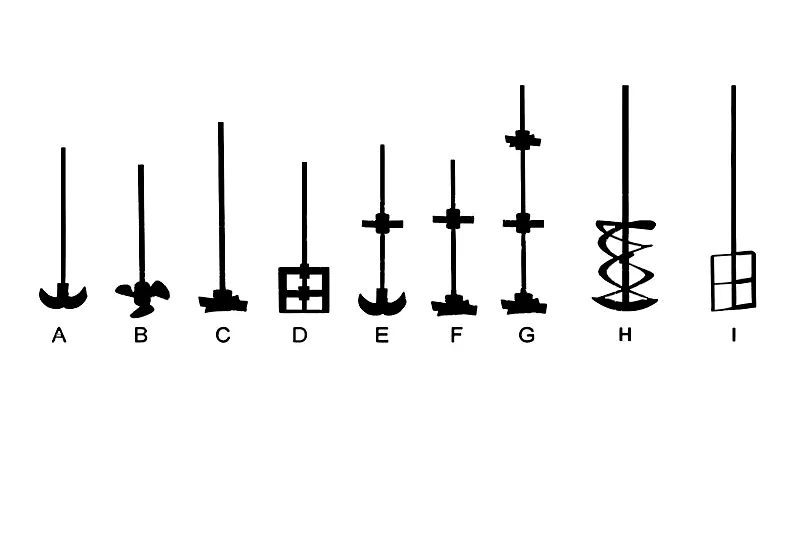

The 100L jacketed glass reactor can be equipped with a variety of stirrer types depending on the reaction medium, viscosity, and process requirements. The selection of the stirring system is critical for ensuring uniform mixing, efficient heat transfer, and optimal reaction performance.

Common Stirrer Types and Applications:

- Pitched Blade Turbine (PBT) Stirrer: Available in 30°, 45°, or 60° blade angles, PBT stirrers produce both axial and radial flow, resulting in more complex flow patterns than flat-blade turbines. They provide higher discharge efficiency and overall better mixing performance, making them more frequently used than flat-blade stirrers.

- Anchor Stirrer: A variation of the flat-blade stirrer, the anchor stirrer has blades that closely follow the vessel wall, acting like a scraper. It is typically operated at low speeds and is suitable for high-viscosity fluids or laminar flow regions.

- Frame Stirrer: Designed for slow-speed operation, frame stirrers generate horizontal annular flow and are generally used under laminar flow conditions. Modifications such as adding vertical blades or crossbars can expand the stirred region and enhance mixing.

- Axial Flow Propeller Stirrer: A three-blade propeller is a typical axial flow stirrer that provides low shear and strong axial circulation. With baffles or flow guides, axial flow can be further enhanced, improving discharge and circulation efficiency. This type is ideal for low-viscosity liquids, heat transfer, suspension reactions, and dissolution in large-volume reactors.

- Flat Blade, Pitched Blade, Curved Blade, or Helical Stirrer: These can be designed as integral or split-type, allowing direct installation on the shaft without removing couplings or other components, offering convenient assembly and maintenance.

- Viscosity-Specific Stirrers: Low-viscosity fluids typically use propeller or turbine stirrers, while high-viscosity fluids are better mixed with anchor, frame, or helical ribbon stirrers.

Selection Considerations:

- Ensure effective mixing, especially for multiphase reactions.

- Achieve high heat transfer efficiency from the vessel walls or internal heat exchange surfaces to the reaction mixture.

- Minimize energy consumption while maintaining sufficient mixing intensity.

- Choose stirrer type according to fluid properties and reactor size:

- For low-viscosity fluids in large-volume reactors, propeller stirrers are preferred due to strong circulation and low power consumption.

- Turbine stirrers are versatile and suitable for a wide range of operations but generally limited to fluids with viscosity below 50 Pa·s.

- For high-viscosity fluids, anchor, frame, screw, or ribbon stirrers are more suitable.

By selecting the appropriate stirrer type and configuration, the 100L jacketed glass reactor can achieve uniform mixing, efficient heat transfer, and stable reaction performance for both laboratory and pilot-scale processes.

Corrosion Resistance & Durability

The 100L jacketed glass reactor uses borosilicate glass or quartz glass as the main wetted materials, providing excellent corrosion resistance. These types of glass exhibit outstanding chemical stability against acids, alkalis, and most organic solvents, and do not easily corrode, leach, or contaminate the reaction system during long-term operation, ensuring the purity of the reaction process and product quality.

Corrosion Resistance Comparison: Borosilicate Glass vs Quartz Glass

| Chemical Medium | Borosilicate Glass | Quartz Glass / Fused Silica |

|---|---|---|

| Hydrochloric acid (HCl) | Excellent, stable for long-term use | Excellent |

| Sulfuric acid ≤80% (H₂SO₄) | Excellent | Excellent |

| Concentrated sulfuric acid >80% | Good (attention at high temperature) | Excellent |

| Nitric acid (HNO₃) | Excellent | Excellent |

| Aqua regia | Good | Excellent |

| Phosphoric acid (H₃PO₄) | Excellent | Excellent |

| Hydrofluoric acid (HF) | Not resistant | Not resistant |

| Sodium hydroxide (NaOH) | Limited resistance (low concentration only) | Poor (corroded at high temperature) |

| Potassium hydroxide (KOH) | Limited resistance | Poor |

| Organic solvents (methanol, ethanol, acetone, DMF, toluene, etc.) | Fully resistant | Fully resistant |

| Halogenated solvents | Excellent | Excellent |

| High-purity chemicals | Good | Excellent |

| Strong alkali at high temperature | Not recommended | Not recommended |

| Photochemical reactions | Suitable | Excellent (high light transmission) |

In practical selection, if the reaction system mainly involves acidic, organic solvent, or neutral media, borosilicate glass is the most cost-effective choice; if high temperatures, strong acids, or photochemical processes are involved, quartz glass offers superior performance.

Application Scenarios

The 100L jacketed glass reactor is mainly positioned for laboratory scale-up and pilot-scale production, especially for processes that require visual monitoring, precise temperature control, and high chemical stability. The reactor vessel, made of borosilicate glass or quartz glass, does not participate in chemical reactions and does not release metal ions or impurities, making it ideal for high-purity and high-value product synthesis.

In the pharmaceutical and biopharmaceutical industries, this reactor is widely used for API and intermediate synthesis, crystallization, recrystallization, and purification. With accurate jacket temperature control and stable agitation, it enables precise control of crystal form, particle size distribution, and reaction kinetics, ensuring excellent batch-to-batch consistency.

In fine chemical and organic synthesis applications, the 100L jacketed glass reactor is commonly used for esterification, condensation, halogenation, nitration, and redox reactions. Its excellent resistance to acids, alkalis, and organic solvents allows long-term stable operation under complex chemical environments.

In polymer and functional material production, this reactor is suitable for resin, polymer, coating, and adhesive synthesis and modification. The jacketed temperature control system can effectively manage exothermic polymerization reactions, helping to achieve stable molecular weight distribution and consistent product performance.

In the flavor, fragrance, food additive, and natural product extraction industries, the inert glass surface prevents contamination of the product, making it ideal for materials that are sensitive to odor, color, and purity.

Overall, the 100L jacketed glass reactor serves as a critical pilot-scale platform bridging laboratory research and industrial production. It is used to verify process feasibility, heat release behavior, and scale-up mixing performance, providing reliable data for future large-scale manufacturing.

Price and Auxiliary Equipment Analysis

The market price for 100L jacketed glass reactors varies widely. Basic manual or standard models typically range from $5,000 to $8,000 USD, while mid-range products with higher automation, digital temperature control, or filtration features usually cost around $10,000 to $15,000 USD. For users requiring integrated systems—including temperature control pumps, vacuum pumps, and safety certifications—the total solution price often exceeds $30,000 USD. When selecting the right configuration, it is recommended to match your budget with process complexity, temperature control precision, and safety requirements.

Key Factors Affecting Market Prices

- Configuration and Level of Automation

- Manual / Standard Models: Basic stirring and temperature control, lower price.

- Digital Display / Temperature Control: More precise control systems, moderately higher price.

- Integrated Packages: Include all-in-one temperature control units, vacuum systems, filtration, etc., significantly increasing the cost.

- Safety and Certification Standards

- Models with certifications such as ETL, CE, or explosion-proof (C1D1) have higher costs.

- Systems complying with GMP/FDA standards command premium prices due to stricter quality requirements.

- Auxiliary Equipment & Accessories

- Stirring motors, vacuum pumps, cooling circulators, and other accessories add to the total project cost.

- Full package systems are usually more expensive than standalone reactors but eliminate the hassle of matching and integrating separate components.

100L Jacketed Glass Reactor — Brand Comparison

| Brand / Model | Typical Price Range | Key Features / Recommendation |

|---|---|---|

| EquilRxnLab AKF‑100L Double Layer Glass Reactor | ~$2,900 USD | China-made with significant price advantage; double-layer glass design; suitable for budget-conscious labs and pilot-scale applications. |

| 100L Chemical Lab Jacketed Glass Reactor (Lab1st) | ~$5,145 USD | Entry-level lab configuration; cost-effective; suitable for basic temperature control and stirring needs. |

| MSE PRO 100L Jacketed Glass Reactors | ~$5,099 USD | Basic research-grade option; reliable for standard reactions on a limited budget. |

| StonyLab 100L Single & Dual Jacketed Glass Reactor | ~$8,300 USD | Supports single/dual jacket design; customizable configurations for diverse applications. |

| HNZXIB 100L Jacketed Glass Reactor | ~$7,500 USD | Standard market configuration; suitable for routine lab and pilot-scale experiments. |

| Ai 100L Single Jacketed Filter Glass Reactor | ~$13,990–$20,990 USD | Mid-range professional reactor; includes optional filtration and enhanced stirring/feeding capabilities. |

| USA Lab 100L Single Jacketed Glass Reactor | ~$11,549–$13,199 USD | US-manufactured standard version; ideal for high-spec research or quality-critical applications. |

| USA Lab 100L Turnkey Jacketed Glass Reactor System | ~$35,939+ USD | High-end integrated system; includes temperature control, vacuum system, and automation; suited for complex processes and large labs. |

Recommended Auxiliary Equipment

To fully utilize the performance of the 100L jacketed glass reactor, the following auxiliary equipment is typically required:

- Temperature Control Equipment: High-temperature oil or water baths, low-temperature circulators, or combined high/low-temperature units. Select the appropriate capacity based on the reaction temperature requirements.

- Vacuum System: Rotary vane pumps or circulating water vacuum pumps for negative pressure operation, distillation, or reduced-pressure reactions.

- Condensation and Collection Devices: Options include rotary condensers, coolers, or collection bottles, suitable for distillation, extraction, and similar processes.

- Auxiliary Instruments: pH meters, temperature sensors, and stirring speed controllers for real-time monitoring and precise control.

By carefully selecting the reactor material, stirring configuration, and supporting equipment, users can optimize investment cost while ensuring performance, allowing the 100L jacketed glass reactor to achieve maximum efficiency in laboratory research, pilot-scale testing, and small-scale production.