Energy efficiency has become a critical focus in various industries due to rising energy costs and increasing environmental concerns. One area where energy efficiency is particularly important is in the design and operation of reactors used in chemical, pharmaceutical, and manufacturing processes. Energy-efficient stainless steel reactors are integral to optimizing production while minimizing operational costs and reducing environmental impact. In this article, we will explore the advantages of these reactors and the significant role they play in improving industrial processes across a range of sectors.

Introduction to Energy-Efficient Stainless Steel Reactors

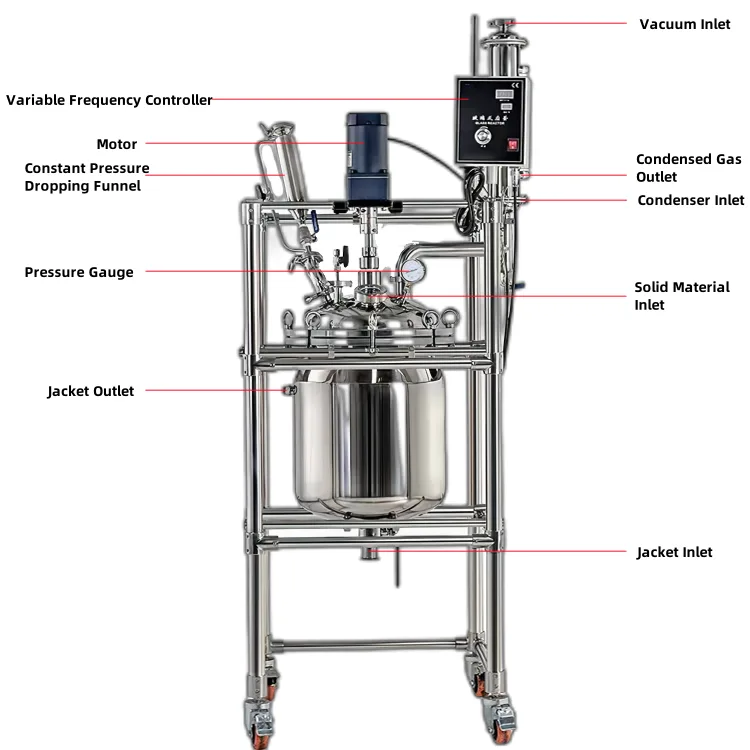

A stainless steel reactor is a vessel used in various industrial processes, including chemical reactions, heat transfer, and material synthesis. Stainless steel is favored for its corrosion resistance, strength, and durability, making it ideal for high-pressure and high-temperature environments. The concept of energy efficiency in reactors revolves around minimizing energy consumption while ensuring optimal reaction conditions. Energy-efficient stainless steel reactors are designed with advanced insulation and heat transfer mechanisms, reducing the need for external heating and cooling sources and ultimately lowering operational energy costs.

In industries that rely on chemical reactions, precise temperature control is crucial for achieving desired product quality and reaction yields. The energy efficiency of these reactors allows for better control over these factors, resulting in enhanced performance and long-term savings.

Benefits of Energy-Efficient Stainless Steel Reactors

1. Cost Reduction

The most immediate benefit of energy-efficient stainless steel reactors is the reduction in energy consumption. By optimizing heat transfer and maintaining consistent internal temperatures, these reactors minimize the need for external heating or cooling systems, which can be energy-intensive and costly. Industries that rely on high-energy processes, such as pharmaceuticals, food processing, and chemical manufacturing, can significantly cut down on their energy bills with the use of energy-efficient reactors.

Furthermore, energy-efficient stainless steel reactors typically have improved insulation, which helps retain heat during exothermic reactions and reduces the amount of energy required to sustain the reaction. As a result, companies can achieve lower operational costs while improving their bottom line.

2. Improved Process Efficiency

The design of energy-efficient stainless steel reactors also enhances the overall efficiency of industrial processes. By maintaining stable reaction temperatures and minimizing heat loss, these reactors allow for more consistent and efficient production cycles. Whether in the production of chemicals, pharmaceuticals, or specialty materials, these reactors help ensure that processes are completed faster, with fewer interruptions or variations.

For example, in the pharmaceutical industry, consistent reaction temperatures are essential for maintaining product quality. Even slight deviations in temperature can lead to inconsistencies in the final product. The enhanced temperature control provided by energy-efficient reactors ensures that these critical parameters are maintained throughout the process.

3. Environmental Impact Reduction

Another key benefit of energy-efficient stainless steel reactors is their ability to reduce the environmental footprint of industrial operations. By decreasing energy consumption, these reactors contribute to lowering greenhouse gas emissions and reducing the consumption of non-renewable energy resources. This is especially important as industries worldwide seek to meet increasingly stringent environmental regulations and sustainability goals.

For companies committed to sustainability, adopting energy-efficient technologies like these reactors is a clear step toward achieving those objectives. Moreover, their energy-saving capabilities align with corporate responsibility efforts, improving the company’s reputation as an environmentally conscious enterprise.

4. Enhanced Safety Features

Safety is a critical concern in industries that involve chemical reactions. Energy-efficient stainless steel reactors come equipped with advanced safety features, such as pressure relief valves, temperature monitoring systems, and explosion-proof designs. These reactors help prevent accidents by ensuring that processes occur under safe and controlled conditions. The energy-efficient design also reduces the likelihood of overheating or excessive energy consumption, which can lead to equipment failure or hazardous situations.

The improved safety provided by these reactors is particularly valuable in high-risk industries such as pharmaceuticals, where the potential consequences of a failure can be severe. With features designed to maintain stable operating conditions, energy-efficient stainless steel reactors enhance both worker safety and product integrity.

5. Customization and Versatility

One of the key advantages of energy-efficient stainless steel reactors is their versatility and the ability to be customized for specific applications. Whether it’s adjusting the reactor’s size, adding specialized coatings, or modifying mixing mechanisms, these reactors can be tailored to meet the exact needs of any industry. For instance, pharmaceutical manufacturers may require reactors with precise temperature controls and specialized mixing mechanisms, while chemical producers may need reactors that can withstand higher pressures and temperatures.

EquilRxnLab offers a wide range of customizable options for their energy-efficient stainless steel reactors, ensuring that clients can find the perfect fit for their operational needs. Customization not only enhances the performance of the reactors but also increases their longevity and reliability.

Applications of Energy-Efficient Stainless Steel Reactors

The energy-efficient stainless steel reactors from EquilRxnLab are ideal for a variety of industries, each benefiting from the reactors’ energy-saving features. Below are some key sectors where these reactors are particularly effective:

- Pharmaceutical Industry: For producing active pharmaceutical ingredients (APIs) and drug formulations, maintaining precise temperature and pressure is critical. The energy-efficient reactors from EquilRxnLab help ensure product quality while reducing energy usage.

- Chemical Manufacturing: From the synthesis of chemicals to the production of polymers and resins, energy-efficient reactors help minimize costs while ensuring optimal conditions for chemical reactions.

- Food and Beverage Industry: In processes such as fermentation, emulsification, and extraction, energy-efficient reactors ensure consistent product quality while lowering energy consumption.

- Materials Science: For synthesizing advanced materials such as polymers and composites, energy-efficient reactors provide the precise control needed for successful outcomes.

For more details on the energy-efficient stainless steel reactors and their applications, visit the product page here.

Conclusion

The energy-efficient stainless steel reactors offer a wide range of benefits, from cost reduction and improved process efficiency to enhanced safety and environmental impact reduction. These reactors are an excellent investment for industries looking to optimize their operations while minimizing energy consumption and reducing their carbon footprint. Companies such as EquilRxnLab provide high-quality, customizable reactors that cater to the specific needs of various industries, ensuring that processes are completed efficiently and safely.

To explore the range of available reactors and learn more about how EquilRxnLab can support your industrial needs, visit our product catalog. For updates and demonstrations, be sure to check out our YouTube channel, and follow us on Instagram and Facebook.