Reliable results form the foundation of pharmaceutical research. You depend on consistent data to advance drug development and ensure patient safety. Glass reactors lead the industry due to their transparency, which allows you to monitor reactions and improve accuracy. Modern systems, such as the AKDF-100L by equilrxnlab, offer precise temperature control and flexible capacity. You can follow updates and demonstrations on YouTube, Instagram, and Facebook or use the contact-us option for personalized support.

Key Takeaways

- Use high-quality glass reactors with precise controls to get consistent and reliable results in pharmaceutical research.

- Perform thorough pre-operation checks and follow proper assembly steps to ensure safe and effective experiments.

- Control stirring speed and temperature carefully to optimize reaction conditions and improve reproducibility.

- Monitor reactions in real time using advanced techniques to detect issues early and maintain quality.

- Maintain safety by wearing protective gear, inspecting equipment regularly, and performing routine maintenance to extend reactor life and prevent accidents.

Reliability in Pharma Research

Consistency in Results

You need consistent results to move pharmaceutical research forward. Reliable data ensures that your findings can be trusted and repeated by others. Modern research highlights the importance of advanced monitoring and modeling techniques in achieving this consistency. For example, recent studies show that using data-driven methods for equipment monitoring helps you detect faults early and maintain optimal conditions. This approach allows you to separate normal batch variations from equipment issues, so you can take action before problems affect your results.

Note: Consistency in your experiments depends on both the quality of your process and the reliability of your equipment. When you use advanced digital tools and real-time monitoring, you reduce the risk of errors and improve the reproducibility of your work.

Modern glass reactor setups play a key role in this process. Their precise control over temperature, pressure, and stirring speed allows you to fine-tune reaction conditions. The transparency of borosilicate glass lets you observe reactions as they happen, so you can make immediate adjustments if needed. These features help you achieve the same results every time, which is essential for pharmaceutical research.

Role of Equipment

Your choice of equipment directly impacts the reliability of your experiments. High-quality, calibrated instruments ensure that your data remains accurate and reproducible. Experts agree that routine checks and proper validation of laboratory equipment are critical steps in avoiding errors. When you start with traceable reference materials and regularly evaluate your instruments, you strengthen the foundation of your research.

A glass reactor with advanced features, such as digital controls and automated data logging, supports real-time monitoring and reduces human error. Safety features like pressure relief valves and reinforced glass construction provide stable conditions for your experiments. By investing in reliable equipment and following standardized protocols, you improve both the quality and consistency of your research outcomes.

Glass Reactor Setup

Pre-Operation Checks

Before you begin any experiment, you must perform thorough pre-operation checks. These steps help you avoid equipment failure and ensure reliable results. Start by confirming that your laboratory has the correct power supply and voltage for your glass reactor. The AKDF-100L, for example, requires a stable electrical connection to support its 9.0 kW heating system and digital controls.

Next, inspect all glass components for cracks, chips, or other damage. High borosilicate glass offers excellent chemical resistance, but even minor flaws can compromise safety and performance. Always check that the glass reactor is compatible with your intended chemicals. The AKDF-100L uses PTFE and borosilicate glass, which handle a wide range of reagents and solvents.

Tip: Review the manufacturer’s guidelines for recommended voltage and chemical compatibility. This step protects both your equipment and your research outcomes.

Finally, verify that all seals, gaskets, and connections are intact. A secure setup prevents leaks and maintains the integrity of your reactions. If you use auxiliary equipment, such as vacuum pumps or condensers, confirm that they function properly before starting your experiment.

Assembly Steps

Proper assembly of your glass reactor sets the stage for successful research. Begin by placing the reactor vessel on a stable, level surface. The AKDF-100L features a durable frame-type rack that provides strong support during operation. Attach the stirring paddle, ensuring it aligns with the motor shaft. The stainless steel paddle, coated with fluorine, resists corrosion and delivers uniform mixing.

Connect the digital temperature control system. The AKDF-100L allows you to set and monitor temperatures up to 200°C with high accuracy. Secure all glass joints using the appropriate clamps and seals. Install the constant pressure funnel and solid feeding port for safe material addition. If your process requires temperature-sensitive handling, consider adding the optional cooling coil or insulation layer.

Attach any auxiliary devices, such as vacuum controllers or spiral condensers, to optimize your setup. Make sure all connections are tight and leak-free. Double-check that the reactor’s stirring speed and temperature controls respond correctly.

Note: Following the assembly instructions from equilrxnlab ensures that you maximize the performance and safety of your glass reactor.

By taking these steps, you create a reliable foundation for your pharmaceutical research. Advanced models like the AKDF-100L offer flexibility, large capacity, and precise control, making them ideal for a wide range of applications.

Operation and Control

Stirring and Mixing

You control the outcome of your pharmaceutical experiments by managing how you stir and mix your reactions. The speed and consistency of mixing directly affect the chemical processes inside your glass reactor. When you use precise stirring protocols, you ensure that reagents distribute evenly, which leads to reliable and repeatable results.

- Slow mixing preserves areas of high reagent concentration. This can accelerate autocatalytic reactions by creating rapid reaction zones.

- Fast mixing creates a uniform solution, which can slow down certain nonlinear reactions by reducing concentration differences.

- Microfluidic studies show that the rate of mixing determines both the speed and the final outcome of autocatalytic reactions.

- Biological processes, such as blood clotting, depend on local concentrations that are influenced by how you mix.

- The timing of mixing compared to the speed of the reaction is critical. When these timescales match, mixing has the greatest effect on your results.

You can see the impact of mixing by observing the uniformity of your solution and checking for sediment. Using dissolvable dyes or monitoring reaction times and yields helps you confirm that your stirring protocol works. The AKDF-100L offers adjustable stirring speeds from 0 to 450 rpm, driven by a corrosion-resistant stainless steel paddle. This flexibility lets you tailor mixing to the needs of each experiment, whether you require gentle agitation or vigorous blending.

Tip: Select the appropriate stirring speed and paddle type for your material’s viscosity. The AKDF-100L supports multiple paddle options, so you can optimize mixing for every reaction.

Temperature Regulation

Precise temperature control is essential for reproducible pharmaceutical research. Even small fluctuations can change reaction rates, product yields, or purity. Digital temperature regulation allows you to set and maintain exact conditions throughout your experiment.

- Digital interfaces let you control multiple reaction parameters at once, improving accuracy and consistency.

- Automated monitoring systems provide real-time alerts and data logging, which help you track trends and analyze your process.

- Regular calibration of temperature sensors and routine maintenance ensure that your readings remain reliable.

- Double jacketed glass reactors offer superior insulation and temperature uniformity, which is especially important for sensitive reactions.

- Monitoring temperature frequently and maintaining cooling fluid levels support stable conditions.

- Automated emergency shutdown and sampling systems improve safety and quality control.

The AKDF-100L features a digital temperature control system with an accuracy of ±1°C, supporting temperatures up to 200°C. Optional enhancements, such as a cooling coil or insulation layer, help you manage temperature-sensitive processes. By using these features, you maintain stable reaction environments and achieve consistent results.

Monitoring Reactions

You need to monitor your reactions in real time to ensure quality and reproducibility. Modern techniques allow you to track reaction progress, detect deviations, and make adjustments as needed.

- Inline near-infrared (NIR) spectroscopy, combined with chemometric analysis, provides real-time monitoring in glass microreactors.

- Integration with spectroscopic detection methods, such as NIR and Raman spectroscopy, enables online reaction monitoring and catalyst characterization.

- These techniques have been validated for use in glass reactor systems, supporting their reliability for pharmaceutical research.

Reaction Progress Kinetic Analysis (RPKA) gives you a powerful way to extract kinetic information from fewer experiments. By using accurate in-situ monitoring, you can quickly gather data on reaction rates and mechanisms. Inline monitoring techniques, such as NIR or Raman spectroscopy, make this possible within your glass reactor setup.

| Aspect | Description |

|---|---|

| Accuracy Thresholds | At least 95% of measurements must fall within strict limits compared to reference values. |

| Confidence Interval | The lower one-sided 95% confidence interval must exceed the threshold for reliability. |

| Reference Method Comparison | Device measurements are compared against laboratory analyzers for validation. |

| ISO 15197:2013 Standard | Sets international accuracy requirements for monitoring systems. |

| Real-World Implications | Ensures batch-to-batch consistency and reliability for end users. |

Multiple Reaction Monitoring (MRM) in mass spectrometry further enhances your ability to quantify target molecules with high specificity and sensitivity. By focusing on specific ion transitions, you reduce background noise and improve the reliability of your results.

Note: The AKDF-100L supports integration with auxiliary equipment, such as vacuum controllers and condensers, which help you monitor and control every aspect of your reaction.

By mastering operation and control, you create a foundation for reliable, reproducible pharmaceutical research. The right equipment, combined with precise protocols, ensures that every experiment delivers trustworthy results.

Safety and Maintenance

Safety Precautions

You must prioritize safety when working with glass reactors in pharmaceutical research. Always wear personal protective equipment (PPE) such as gloves, safety glasses, and long-sleeved clothing. This gear protects you from chemical splashes and accidental contact with hot surfaces. Before starting any procedure, check that all safety devices, including pressure relief valves and emergency shut-off switches, function correctly. Never operate the reactor if you notice cracks or chips in the glassware. Damaged glass can fail under pressure or temperature changes, putting you at risk.

Tip: Train all laboratory staff on chemical hazards and the correct use of PPE. Regular training sessions help everyone stay updated on the latest safety protocols.

Routine Maintenance

Routine maintenance keeps your glass reactor in optimal condition and extends its lifespan. Inspect seals, gaskets, and connections regularly for signs of wear or leaks. Replace any worn components immediately to prevent equipment failure. Lubricate moving parts, such as the stirring mechanism, according to the manufacturer’s instructions. Check the calibration of digital controls and temperature sensors to ensure accurate readings. Schedule preventive maintenance and document each inspection. This approach helps you identify issues early and maintain a safe working environment.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect seals/gaskets | Weekly | Prevent leaks |

| Calibrate sensors | Monthly | Ensure accurate measurements |

| Lubricate moving parts | As needed | Reduce wear and noise |

| Replace worn parts | Immediately | Maintain safety and function |

Cleaning and Storage

Proper cleaning and storage practices protect both your equipment and your research results. Use mild detergent solutions to clean glassware, and rinse thoroughly with deionized water. Avoid harsh chemicals that can damage sensitive surfaces or release hazardous fumes. Remove debris gently with soft cloths or brushes to prevent scratches. After cleaning, inspect each piece for cracks or chips and discard any damaged items.

Store your glass reactor and accessories in a clean, dry, and organized area. Use protective covers or sealed containers to keep dust and contaminants away. Label storage areas clearly to minimize handling and prevent mix-ups. Ongoing training and regular updates to cleaning protocols ensure that everyone follows consistent safety standards.

Note: Preventive maintenance and careful storage reduce contamination risks and improve the reliability of your pharmaceutical research.

Troubleshooting Glass Reactor Issues

Vacuum Loss

You may notice a sudden drop in vacuum pressure during operation. This issue often results from loose connections, worn seals, or micro-cracks in the glass. Start by inspecting all joints and seals. Tighten clamps and replace any damaged gaskets. Examine the glass vessel for chips or cracks that could compromise the vacuum. If you use auxiliary equipment like vacuum pumps, check for leaks in hoses or fittings. A simple soap solution can help you spot escaping air bubbles. Maintaining a stable vacuum ensures your reactions proceed under controlled conditions.

Tip: Regularly test your system for leaks before starting sensitive experiments. Early detection prevents unexpected interruptions.

Bearing and Seal Problems

Bearings and seals play a critical role in the smooth operation of your glass reactor. If you hear unusual noises or see leaks near the stirring shaft, you may have worn bearings or faulty seals. Shut down the reactor and inspect the stirring assembly. Replace bearings that show signs of wear or corrosion. Check PTFE and fluororubber seals for deformation or chemical attack. Lubricate moving parts as recommended by the manufacturer. Consistent maintenance of these components reduces downtime and protects your research.

| Problem | Possible Cause | Solution |

|---|---|---|

| Shaft wobble | Worn bearing | Replace bearing |

| Fluid leakage | Damaged seal | Install new seal |

| Noise/vibration | Dry or corroded part | Lubricate or replace |

Valve and Condenser Issues

Valves and condensers control the flow and temperature of your reactions. Blockages, leaks, or improper operation can disrupt your process. You should inspect valves for residue buildup and ensure they open and close smoothly. Clean or replace clogged condenser coils to maintain efficient cooling. Simulation studies in complex reactor systems show that timely valve management prevents dangerous temperature rises and keeps operations within safe limits. These findings highlight the importance of proactive checks and quick interventions. By monitoring and maintaining these components, you avoid accidents and ensure reliable results.

Note: Schedule routine inspections of valves and condensers. Preventative action keeps your glass reactor running safely and efficiently.

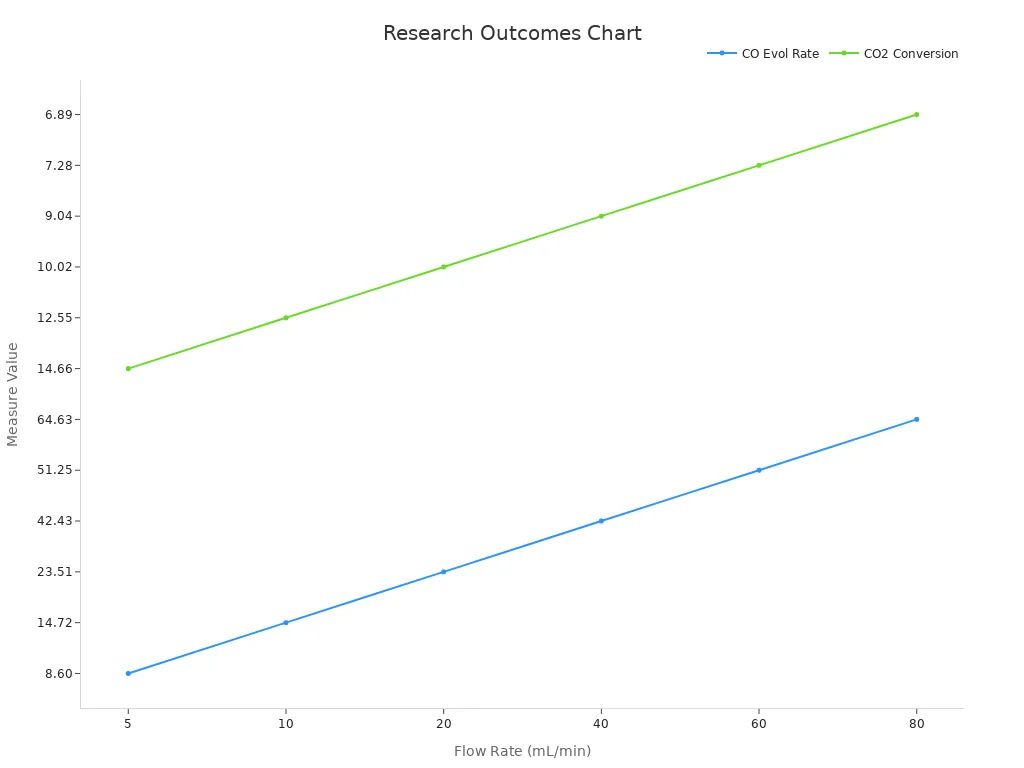

You achieve reliable results in pharmaceutical research by following a systematic approach. Start with careful setup, precise operation, and strict safety protocols. Maintain your glass reactor regularly to ensure consistent performance. The table below highlights how advanced reactor techniques improve outcomes, with higher CO evolution rates and optimized conversion:

| Flow Rate (mL/min) | Residence Time (min) | CO Evolution Rate (mmol gcat⁻¹ h⁻¹) | CO2 Conversion (%) |

|---|---|---|---|

| 5 | 20 | 8.60 | 14.66 |

| 10 | 10 | 14.72 | 12.55 |

| 20 | 5 | 23.51 | 10.02 |

| 40 | 2.5 | 42.43 | 9.04 |

| 60 | 1.67 | 51.25 | 7.28 |

| 80 | 1.25 | 64.63 | 6.89 |

| 0 (stagnation) | N/A | N/A | 17.95 (thermal equilibrium) |

Consult equilrxnlab for expert guidance and advanced solutions. Keep improving your methods to drive ongoing reliability in your research.

FAQ

What makes the AKDF-100L suitable for pharmaceutical research?

You benefit from the AKDF-100L’s precise digital temperature control, large 100-liter capacity, and chemical-resistant materials. These features help you achieve consistent, reproducible results in a wide range of pharmaceutical applications.

How do you ensure safe operation of a glass reactor?

You should inspect all glassware for damage, confirm secure connections, and wear proper PPE. Always follow the manufacturer’s safety guidelines. Regular training and routine checks help you maintain a safe laboratory environment.

Can you use the AKDF-100L with different chemicals?

Yes, you can. The AKDF-100L uses high borosilicate glass and PTFE, which resist most acids, bases, and solvents. Always verify chemical compatibility before starting your experiment.

How often should you perform maintenance on your glass reactor?

You should inspect seals, gaskets, and moving parts weekly. Calibrate sensors monthly. Replace worn components immediately. Routine maintenance ensures reliable performance and extends equipment lifespan.

What auxiliary equipment can you connect to the AKDF-100L?

You can connect vacuum pumps, condensers, cooling or heating circulators, and vacuum controllers. These accessories help you optimize reaction conditions and improve process control.