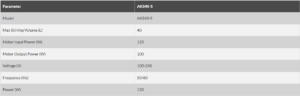

1. Introduction: The Background of Green Chemistry

As environmental concerns grow, green chemistry has become a key focus in modern chemical research. The goal of green chemistry is to reduce the negative environmental impact of chemical processes by designing reactions that are more efficient and using materials that are less harmful. Laboratory equipment and technology play a crucial role in achieving these objectives, helping researchers implement more sustainable reactions.

2. The 12 Principles of Green Chemistry

Green chemistry is guided by 12 principles, aimed at reducing waste, increasing resource efficiency, using renewable materials, and avoiding toxic substances. Some key principles related to lab equipment include:

- Reducing By-Products: Optimizing reaction conditions can minimize by-product formation. For example, precise control of temperature and pressure reduces waste in reactions.

- Energy Efficiency: Using energy-efficient devices like low-temperature baths or reactors can significantly reduce energy consumption during experiments.

- Using Green Solvents: Many reactions require solvents, but green solvent systems can decrease the reliance on organic solvents, lowering environmental impact.

3. Equipment in Green Chemistry

Implementing green chemistry in labs relies on advanced equipment. Here are some commonly used devices in green chemistry research and their roles:

- Low-Temperature Reaction Baths: Ideal for low-energy chemical reactions, these devices help minimize energy consumption and heat loss, making reactions more efficient.

- Stainless Steel Reactors: Durable and reusable, these reactors reduce material waste. High-pressure reactors, in particular, allow for faster reactions at elevated temperatures, reducing reaction time and by-products.

- Solvent Recycling Systems: Green chemistry encourages the use of renewable solvents. Recycling systems help laboratories minimize solvent waste and reduce the release of harmful substances.

4. Laboratory Waste Management and Recycling

Another critical aspect of green chemistry is managing laboratory waste. Traditional experiments may generate significant waste, but modern equipment can minimize this impact:

- Distillation Equipment: Used to recover and reuse solvents, this equipment reduces overall solvent consumption in the lab.

- Catalytic Reactors: Green chemistry reactions often use catalysts to improve efficiency and reduce resource consumption. Catalytic reactors can lower waste production and energy usage.

5. Case Study: Green Chemistry in Action

A practical application of green chemistry can be seen in solvent replacement. In an organic synthesis experiment, researchers used a solvent recycling system to substitute traditional organic solvents with water-based ones, drastically reducing solvent consumption. Additionally, using a stainless steel reactor for high-pressure synthesis reduced the reaction time by 50% and cut by-product formation by 30%.

6. Future Trends: Automation and Smart Laboratories

With advancements in laboratory technology, automation is helping green chemistry evolve further. Automated reactors and real-time monitoring systems enable researchers to optimize every step of a reaction, minimizing human and energy waste. For example, smart reactors can adjust temperature, pressure, and stirring speed automatically based on experimental data, ensuring each reaction is conducted under the most efficient conditions.

7. Conclusion

Green chemistry is not just a concept—it relies on modern laboratory equipment to be realized. By using energy-efficient devices, recycling systems, and catalytic technologies, laboratories can reduce their environmental impact without compromising experimental results. As automation and smart technology continue to advance, green chemistry will become even more widespread in modern laboratories.