Achieving Precise Thermal Control Across a Wide Range of Applications

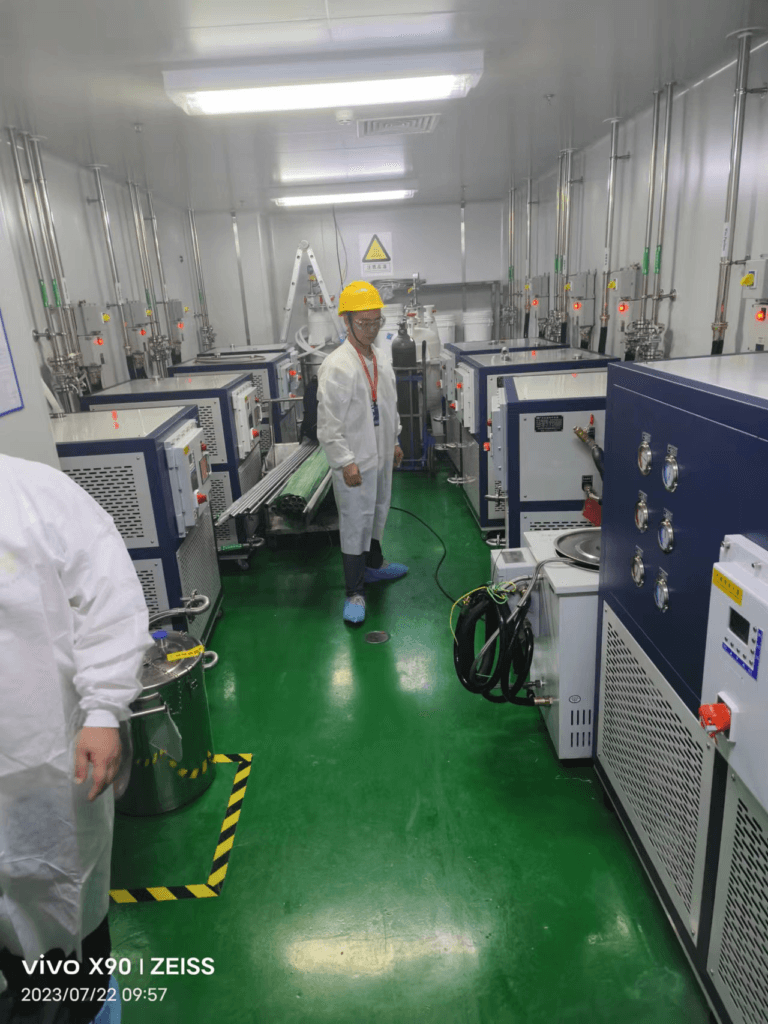

In laboratories and industrial settings where temperature precision is critical, the high and low temperature integrated machine has emerged as a versatile and indispensable tool. These systems are designed to deliver consistent and accurate thermal control across a wide temperature range, enabling processes that demand both extreme heat and cooling capabilities. This article explores the technology, applications, and advancements in high and low temperature integrated machines, with a focus on EquilRxnLab’s AKGD-100L model, a state-of-the-art solution for high-performance thermal management.

Understanding High and Low Temperature Integrated Machine Technology

A high and low temperature integrated machine combines heating and cooling functionalities into a single system, allowing users to achieve precise temperature control from as low as -20°C to as high as 200°C. This dual capability eliminates the need for separate heating and cooling devices, streamlining workflows and saving valuable lab space. The AKGD-100L model from EquilRxnLab exemplifies the latest advancements in this technology, featuring a robust design and adaptive temperature control to achieve ±0.1°C accuracy.

The AKGD-100L’s ability to maintain consistent temperatures across a wide range makes it ideal for sensitive processes where even minor fluctuations can compromise results. Engineers and researchers can explore the AKGD-100L’s specifications here.

Key Applications of High and Low Temperature Integrated Machines

- Chemical Synthesis

In reactions requiring precise temperature control, such as polymerization or crystallization, the ability to switch between heating and cooling is essential. The AKGD-100L’s rapid temperature adjustment capabilities ensure optimal reaction conditions, reducing process times while maintaining reproducibility. - Materials Testing

From thermal conductivity measurements to fatigue studies, high and low temperature integrated machines provide the uniform temperature control needed for accurate results. This reliability is particularly valuable in industries like aerospace and automotive, where material performance under extreme conditions is critical. - Pharmaceutical Development

Stability testing of drug formulations often requires prolonged exposure to controlled temperatures. The AKGD-100L’s uniform temperature distribution eliminates gradients, ensuring consistent and reliable results.

For specialized applications, EquilRxnLab offers customizable configurations. Visit their product catalog to explore options tailored to your needs.

Advantages of Modern High and Low Temperature Integrated Machines

Modern systems like the AKGD-100L integrate advanced features to enhance safety, efficiency, and usability:

- Overheating and Overcooling Protection: Automated shutoffs prevent hazardous temperature spikes or drops, ensuring safe operation.

- Energy Efficiency: Insulated designs minimize heat loss or gain, reducing energy consumption and operational costs.

- User-Friendly Interfaces: Touchscreen controls and real-time data logging simplify complex workflows, making the system accessible to users of all experience levels.

EquilRxnLab’s commitment to innovation is evident in their YouTube tutorials, which provide hands-on guidance for optimizing system performance.

Integrating High and Low Temperature Integrated Machines into Workflows

Adopting these systems requires careful planning to ensure seamless integration:

- Coolant and Heating Medium Selection: Choosing the right coolant and heating medium is essential for achieving desired temperature ranges.

- Maintenance: Regular maintenance, including fluid replacement and sensor calibration, is essential to maintain performance and longevity.

- Space Optimization: Compact designs like the AKGD-100L fit seamlessly into crowded labs, maximizing workspace efficiency.

For tailored advice, connect with EquilRxnLab’s experts via their contact page.

Future Trends in Thermal Management Technology

The future of high and low temperature integrated machines lies in smart automation and sustainability:

- IoT Integration: Sensors and cloud-based platforms enable predictive maintenance, reducing downtime and improving efficiency.

- Eco-Friendly Fluids: Bio-based coolants and heating fluids are gaining traction as industries seek to minimize environmental impact.

- AI-Driven Optimization: Machine learning algorithms analyze historical data to refine temperature profiles for specific processes, enhancing precision and reproducibility.

EquilRxnLab stays at the forefront of these trends, sharing insights through Instagram updates and Facebook community posts.

Final Insights

As industries and research institutions continue to push the boundaries of science and technology, the demand for reliable thermal management tools like the high and low temperature integrated machine will only grow. EquilRxnLab’s AKGD-100L stands out not only for its technical excellence but also for its adaptability to evolving challenges. By combining precision engineering with user-centric design, it empowers researchers and engineers to achieve reproducible, high-quality results—whether synthesizing novel compounds, testing advanced materials, or developing life-saving pharmaceuticals.