Exploring Innovations in High-Temp Oil Bath Reactor Technology

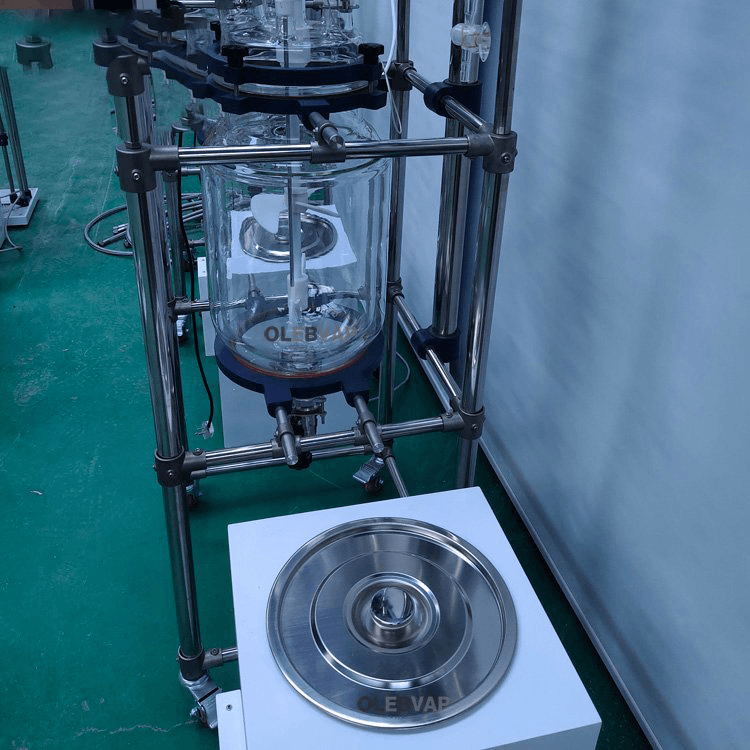

In the realm of advanced laboratory research, precision equipment plays a pivotal role in driving scientific breakthroughs. Among these, the High-Temp Oil Bath Reactor stands out as a critical apparatus for experiments that require uniform heating and controlled reaction environments. Developed by EquilRxnLab, this reactor has been engineered to support a broad range of applications in chemical synthesis, material science, and process engineering. Detailed specifications and product features can be reviewed on our product page.

Design and Engineering Excellence

Innovative Materials and Structural Integrity

The success of advanced laboratory reactors is deeply rooted in their design and the materials used. EquilRxnLab’s approach involves the integration of high-quality components that ensure durability and precision under extreme conditions. The reactor’s construction incorporates specially formulated alloys and robust insulation, which together guarantee that experimental conditions remain stable and reproducible over extended periods.

Advanced computational modeling has played a significant role in perfecting the design. Engineers simulate various scenarios to predict thermal distribution and mechanical stresses, ensuring that every part of the reactor withstands high temperatures without compromising safety or performance. This meticulous design process is one of the hallmarks of the High-Temp Oil Bath Reactor, delivering unmatched reliability in demanding laboratory environments.

Applications in Diverse Research Fields

Expanding the Horizons of Laboratory Science

Modern research requires equipment that can adapt to a variety of experimental conditions. The High-Temp Oil Bath Reactor is versatile enough to be employed across multiple disciplines. In chemical synthesis, for instance, precise temperature control is essential for achieving desired reaction kinetics and product purity. This reactor is particularly beneficial for processes where consistent heat distribution is crucial, such as in polymerization and catalysis studies.

In the field of material science, researchers utilize the reactor for the thermal treatment of advanced materials. Its ability to maintain stable conditions facilitates the development of new compounds and the exploration of their physical properties. Pharmaceutical research also benefits from this technology, where the reproducibility of reaction conditions is imperative for drug formulation and stability testing.

Furthermore, environmental engineering applications, including the study of thermal degradation of pollutants, also rely on such sophisticated reactor systems. Detailed operational guidelines and application examples are available in our product catalog.

Optimization and Operational Strategies

Maximizing Efficiency through Precise Control

Achieving optimal performance from complex reactor systems requires a combination of precise control and advanced monitoring techniques. Operators are encouraged to calibrate temperature, pressure, and stirring mechanisms meticulously. The integration of digital control systems enables real-time adjustments, ensuring that experimental conditions remain within the desired parameters throughout the process.

Routine data logging and sensor feedback are critical in identifying performance trends and potential areas for improvement. Advanced automation technologies further enhance the functionality of the reactor by reducing human error and streamlining operational workflows. Regular calibration and periodic maintenance ensure that the reactor continues to operate at peak efficiency, thereby supporting consistent experimental results.

Guidelines for maintenance and operational procedures can be obtained by reaching out via our contact page.

Maintenance, Safety, and Longevity

Best Practices for Sustained Performance

In any high-temperature operation, safety and regular maintenance are paramount. The design of the High-Temp Oil Bath Reactor includes several built-in safety features, such as pressure relief valves and thermal cutoffs, which protect both the equipment and the operators. Establishing a rigorous maintenance schedule is essential to prevent the accumulation of residues and ensure the reactor’s longevity.

Routine cleaning using appropriate, non-corrosive agents is recommended to maintain the integrity of the reactor’s internal surfaces. Regular inspections help detect any early signs of wear or degradation, allowing for timely interventions. Training for laboratory personnel on proper operational protocols is equally important, ensuring that all safety measures are effectively implemented.

To stay updated on the latest maintenance practices and safety protocols, follow EquilRxnLab on YouTube, Instagram, and Facebook.

Integration of Digital Technologies

Embracing Modern Automation and Data Analytics

The integration of digital technologies has revolutionized the operation of laboratory reactors. Incorporating real-time data analytics, machine learning, and IoT sensors enables researchers to monitor and adjust experimental parameters dynamically. This digital transformation minimizes the likelihood of human error and enhances the overall reliability of the reactor system.

The High-Temp Oil Bath Reactor benefits significantly from these technological advancements. Data-driven insights allow for predictive maintenance, ensuring that potential issues are addressed before they escalate into major problems. Enhanced connectivity also facilitates remote monitoring, giving researchers the flexibility to manage experiments from different locations. These technological integrations represent a significant step forward in laboratory reactor design, aligning with the ongoing evolution of research methodologies.

Future Directions and Emerging Trends

Anticipating Innovations in Reactor Technology

As research demands continue to evolve, the need for more advanced reactor systems grows. Future developments are likely to focus on further improving the thermal efficiency and safety features of high-temperature reactors. Emerging materials and innovative engineering solutions promise to extend the operational limits of these systems, making them even more reliable for a wider range of applications.

The development of modular reactor systems is another trend gaining momentum. These systems offer the flexibility to adapt to various experimental setups and can be customized to meet specific research needs. EquilRxnLab is at the forefront of these innovations, continuously exploring new ideas and technologies to enhance reactor performance.

In the coming years, the integration of artificial intelligence and advanced analytics is expected to further optimize reactor operations. Such advancements will not only streamline processes but also contribute to significant energy savings and improved experimental outcomes. Researchers and industry experts are excited about the potential of these technologies to redefine the standards of laboratory research.

The intricate design, diverse applications, and advanced operational strategies of the High-Temp Oil Bath Reactor underscore its significance in modern scientific research. With EquilRxnLab leading the way in innovation, this reactor continues to support groundbreaking experiments while ensuring high levels of safety and efficiency. For further details on product specifications and to explore additional resources, visit our product page. Engage with our community on YouTube, Instagram, and Facebook to stay informed about the latest trends and updates. Continued exploration and adherence to advanced research practices will undoubtedly pave the way for new scientific discoveries, reinforcing the vital role of the High-Temp Oil Bath Reactor in experimental science.