Controlled temperature conditions are essential for efficient and reproducible chemical reactions. A Liftable Glass Reactor with Cooling Circulator is designed to:

- Maintain optimal reaction temperatures through integrated heating and cooling

- Enhance operational flexibility with an electric lifting system

- Ensure uniform reactant distribution via advanced stirring mechanisms

- Support scalability, from lab-scale experiments to industrial production

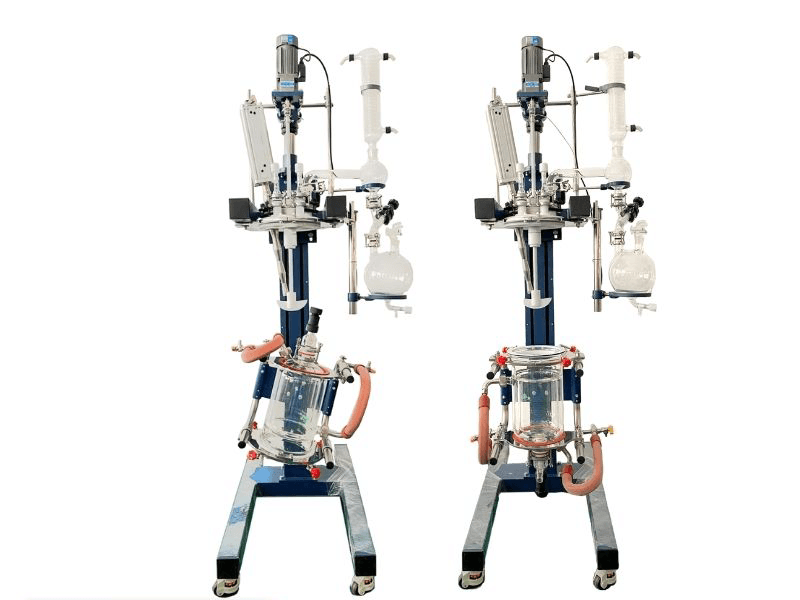

The 20L Lifting and Rotating Double-Layer Glass Reactor from EquilRxnLab combines state-of-the-art engineering with reliable performance, making it a versatile solution for chemical and pharmaceutical applications.

Key Features of a Liftable Glass Reactor with Cooling Circulator

1. Precision Temperature Regulation with Cooling Circulator

Maintaining a stable reaction temperature is critical for reaction kinetics and product purity. A Liftable Glass Reactor with Cooling Circulator offers:

- Efficient heat dissipation, preventing thermal degradation of sensitive compounds

- Integrated cooling circulator, ensuring rapid temperature adjustments

- Double-layer glass design, allowing uniform heat distribution and controlled cooling

EquilRxnLab’s reactor supports a broad temperature range, making it ideal for endothermic and exothermic reactions.

2. Automated Lifting System for Operational Efficiency

A Liftable Glass Reactor with Cooling Circulator features an electric lifting mechanism, providing:

- Easy vessel access for material loading and sample extraction

- Reduced operator exposure, improving laboratory safety

- Quick maintenance, minimizing downtime between reactions

This functionality is particularly beneficial for multi-step reactions that require precise control over reactant addition and phase transitions.

3. Advanced Stirring Mechanism for Homogeneous Mixing

Uniform reactant distribution is essential for high-yield chemical synthesis. The stirring system in a Liftable Glass Reactor with Cooling Circulator offers:

- Adjustable speed controls, enabling fine-tuned reaction kinetics

- Efficient mixing, ensuring consistent product formation

- Stable agitation, enhancing mass and heat transfer efficiency

The 20L Lifting and Rotating Double-Layer Glass Reactor integrates high-performance stirring technology, optimizing reaction conditions for diverse chemical processes.

Advantages of Using a Liftable Glass Reactor with Cooling Circulator

✅ Precise Temperature Control – Ensures stable reaction conditions for consistent product quality

✅ Improved Safety – Minimizes operator exposure to hazardous chemicals

✅ Enhanced Efficiency – Reduces manual intervention with automated lifting and cooling

✅ Scalability – Supports seamless process transition from lab-scale to industrial production

✅ Versatile Applications – Ideal for pharmaceuticals, polymers, and material synthesis

The reactor’s integrated cooling and lifting systems provide an advanced solution for temperature-sensitive reactions.

Applications of a Liftable Glass Reactor with Cooling Circulator

A Liftable Glass Reactor with Cooling Circulator is widely used in:

- Pharmaceutical Research – Facilitates API synthesis and crystallization under controlled conditions

- Polymer Science – Supports precise polymerization reactions with thermal regulation

- Material Synthesis – Enables controlled nanoparticle formation and advanced material processing

- Fine Chemicals Production – Ensures consistent reaction yields and purity

The broad adaptability of this reactor makes it a cornerstone in chemical laboratories and pilot plants.

Choosing the Right Liftable Glass Reactor with Cooling Circulator

To select an optimal reactor, consider:

- Temperature Range Requirements – Ensuring compatibility with specific reaction conditions

- Cooling System Efficiency – Selecting a circulator with fast heat dissipation capabilities

- Lifting Mechanism – Choosing automated systems for enhanced operational control

- Material Compatibility – Opting for borosilicate glass for chemical resistance and thermal stability

Explore EquilRxnLab’s complete reactor catalog for additional configurations.

Why Choose EquilRxnLab’s Liftable Glass Reactor with Cooling Circulator?

EquilRxnLab provides:

- Cutting-Edge Technology – Precision-engineered high-performance reactors

- Reliable Quality – Designed for long-term stability and reproducibility

- Comprehensive Support – Expert guidance for customized reactor solutions

For tailored reactor systems, contact EquilRxnLab today.

Stay Connected for the Latest Innovations

Follow EquilRxnLab on social media for updates on advanced reactor technology:

Revolutionizing Chemical Processing with Precision and Control

A Liftable Glass Reactor with Cooling Circulator ensures unmatched temperature regulation and operational efficiency in chemical synthesis and material science. EquilRxnLab’s 20L Lifting and Rotating Double-Layer Glass Reactor provides superior control, supporting innovative research and industrial applications.