In modern research laboratories, precise temperature control is essential for the success of complex experiments. Among the innovative tools developed for this purpose, the Low temperature liquid circulating pump has emerged as a pivotal solution. Designed to maintain stable, low-temperature environments while ensuring efficient liquid circulation, this technology supports a wide range of scientific studies and industrial processes. As research demands become increasingly rigorous, EquilRxnLab continues to push the boundaries of pump technology with its state-of-the-art solutions. For detailed product specifications and features, please visit our product page.

Design and Engineering of the Low temperature liquid circulating pump

Innovative Structural Features and Material Selection

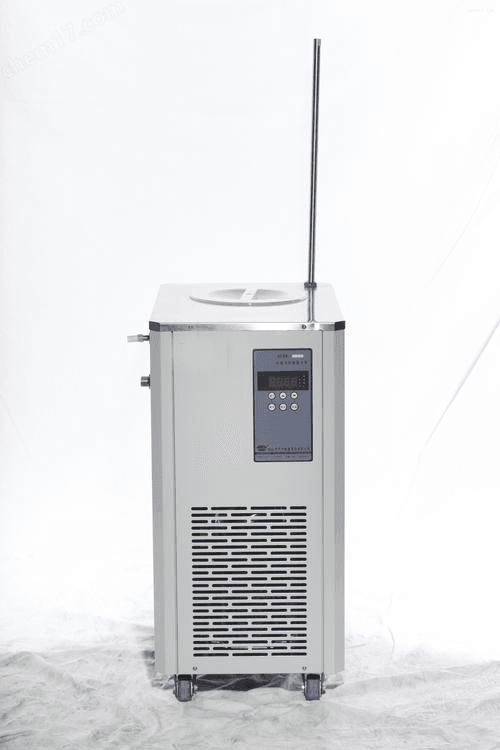

The development of the Low temperature liquid circulating pump represents a significant advancement in pump engineering. EquilRxnLab has leveraged high-grade materials and precision manufacturing techniques to construct a pump that meets the strict demands of low-temperature applications. Key design elements include robust housings, corrosion-resistant components, and efficient fluid dynamics that ensure consistent performance even under prolonged operation.

Advanced simulation tools have been employed to optimize the internal flow paths and minimize thermal losses. This rigorous engineering process results in a pump that not only delivers superior cooling performance but also ensures longevity and reliability. The careful integration of these features underscores the pump’s capability to perform under challenging laboratory conditions, thus supporting high-precision experiments and industrial processes alike.

Diverse Applications in Scientific Research and Industry

Expanding Research Capabilities with Innovative Pump Technology

The versatility of the Low temperature liquid circulating pump makes it an indispensable component in various fields of research. In chemical and biochemical laboratories, maintaining a controlled low-temperature environment is critical for reaction stability and sample integrity. The pump’s ability to circulate coolant efficiently allows researchers to achieve the precise temperature conditions required for sensitive experiments.

Moreover, the pump finds extensive applications in materials science, where temperature regulation is crucial during processes such as crystallization and polymerization. Its consistent performance ensures that reactions occur under ideal conditions, thus enhancing reproducibility and data accuracy. Additionally, environmental studies and industrial processes benefit from the pump’s capacity to manage thermal conditions effectively, contributing to improved process control and energy efficiency.

For further product details and related equipment, explore our product catalog.

Optimization Strategies for Enhanced Pump Performance

Maximizing Efficiency Through Advanced Control Systems

Achieving optimal performance from laboratory equipment requires precise calibration and continuous monitoring. Operators of the Low temperature liquid circulating pump are advised to fine-tune parameters such as flow rate, coolant temperature, and operational timing to match experimental needs. Modern digital controllers and sensor arrays can be integrated with the pump system to provide real-time feedback and adjustments, thereby maintaining optimal operating conditions throughout the experimental cycle.

Incorporating automated control systems not only improves efficiency but also enhances safety by reducing the risk of human error. Routine calibration and scheduled maintenance checks are integral to preserving the pump’s high performance over time. These proactive measures ensure that the pump consistently delivers reliable performance, even in the most demanding laboratory settings.

For personalized support and additional information, please visit our contact page.

Maintenance and Safety Considerations

Ensuring Longevity with Regular Upkeep and Precautionary Measures

The continuous operation of sensitive laboratory equipment necessitates a well-defined maintenance protocol. The Low temperature liquid circulating pump is designed for ease of maintenance, with accessible components that allow for thorough cleaning and inspection. Regular maintenance routines, including the use of non-corrosive cleaning agents and periodic component checks, are essential for sustaining pump performance and preventing downtime.

Safety is paramount in any laboratory environment, and operating at low temperatures adds another layer of complexity. It is crucial that operators adhere to established safety protocols and guidelines. This includes regular training on the proper use of the pump and the implementation of emergency shutdown procedures. Such practices help mitigate risks and ensure a secure operational environment for all personnel involved.

Ongoing engagement with our expert support team at EquilRxnLab can provide further insights into best practices for maintenance and safety. Stay connected by following us on YouTube, Instagram, and Facebook.

Future Trends and Technological Advancements

Innovating for Tomorrow’s Research Needs

Looking ahead, the evolution of pump technology is set to further enhance laboratory efficiency and experimental precision. Emerging trends in automation, digital integration, and material science are poised to redefine the operational capabilities of cooling and circulation systems. The Low temperature liquid circulating pump is at the forefront of these advancements, with ongoing research dedicated to improving energy efficiency, reducing maintenance requirements, and enhancing overall performance.

Innovations in sensor technology and real-time data analytics are expected to revolutionize how pump systems are managed, enabling predictive maintenance and autonomous operation. These developments will not only streamline laboratory workflows but also open new avenues for research by ensuring that experimental conditions remain consistently optimal.

EquilRxnLab remains committed to pioneering these technologies and delivering products that meet the evolving demands of scientific research. Researchers and industry professionals can look forward to a future where enhanced pump performance leads to greater experimental accuracy and more reliable data outcomes.

The journey toward more efficient laboratory fluid management systems continues to gain momentum with the integration of advanced pump technologies. The Low temperature liquid circulating pump exemplifies the synthesis of innovative design, robust engineering, and practical functionality. By addressing the challenges of temperature regulation and fluid circulation in low-temperature environments, this pump has established itself as a critical component in modern scientific research and industrial processes.

For further details on product specifications and to explore additional innovations, please visit our product page. Engage with EquilRxnLab’s dynamic community on YouTube, Instagram, and Facebook to stay informed about the latest developments in pump technology and related research. Ongoing collaboration, continuous innovation, and a commitment to excellence ensure that the advancements in laboratory fluid management will keep propelling scientific discovery forward.