Introduction to Multi-Manifold Vacuum Freeze Dryers

In laboratory and industrial settings, efficient drying of sensitive materials is crucial to preserving their integrity and extending their shelf life. One of the most effective methods to achieve this is lyophilization, also known as freeze-drying. A key piece of equipment in this process is the Multi-Manifold Vacuum Freeze Dryer, which plays a vital role in ensuring consistent and effective drying of samples. This article explores the features and benefits of this advanced equipment and how it contributes to optimizing lyophilization processes.

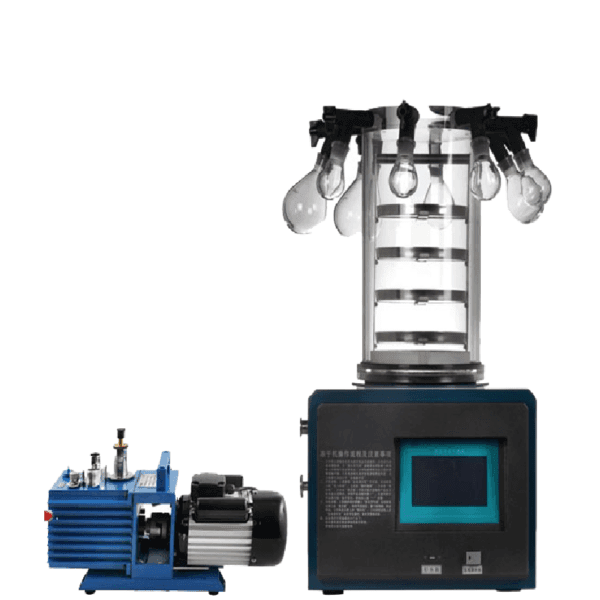

What is a Multi-Manifold Vacuum Freeze Dryer?

A Multi-Manifold Vacuum Freeze Dryer is a specialized drying system designed for the sublimation of water from frozen samples under vacuum conditions. The system consists of multiple manifolds, each capable of handling several vials or containers simultaneously. This feature makes the device particularly advantageous in high-throughput laboratory settings, where efficiency and scalability are essential.

The basic working principle of a vacuum freeze dryer involves freezing the material, reducing the surrounding pressure, and applying heat to allow water to sublimate directly from solid ice to vapor without passing through the liquid phase. This technique is especially beneficial for preserving delicate compounds, including pharmaceuticals, biological samples, and food products, without compromising their quality.

Key Features of Multi-Manifold Vacuum Freeze Dryers

The Multi-Manifold Vacuum Freeze Dryer is equipped with several features that make it a valuable tool for laboratories and industries involved in freeze-drying processes. Some of the most notable features include:

- Multiple Manifolds for High-Throughput

The inclusion of multiple manifolds allows for the drying of several samples at once, which significantly increases productivity. Each manifold can operate independently, offering flexibility in managing different types of samples with varying requirements. - Vacuum Control for Optimal Drying Conditions

Precise vacuum control is essential for efficient lyophilization. The multi-manifold system ensures that each manifold maintains optimal pressure for sublimation, which leads to faster and more uniform drying across all samples. - Temperature Control

Proper temperature regulation is crucial in freeze-drying to prevent degradation or loss of activity in sensitive compounds. Multi-manifold systems come with advanced temperature control, which ensures that each sample is dried at the right conditions for optimal preservation. - Modular Design for Customization

The modular design of the Multi-Manifold Vacuum Freeze Dryer allows laboratories to customize the equipment according to specific needs. Users can expand or modify the system to handle larger volumes or to incorporate additional features such as automated loading and unloading systems. - Energy Efficiency

Modern multi-manifold systems are designed with energy efficiency in mind, utilizing advanced technologies to minimize energy consumption during the freeze-drying process. This feature helps reduce operational costs and makes these systems more sustainable.

Applications of Multi-Manifold Vacuum Freeze Dryers

The Multi-Manifold Vacuum Freeze Dryer is used across a wide range of industries, particularly those requiring precise control over the drying of sensitive materials. Some of the key applications include:

- Pharmaceuticals and Biotechnology

In the pharmaceutical industry, freeze-drying is often used to preserve vaccines, proteins, and other biologics. The Multi-Manifold Vacuum Freeze Dryer ensures that these sensitive materials are preserved without losing efficacy or potency. - Food Industry

Freeze-drying is also commonly used in the food industry to create dehydrated food products. The multi-manifold system allows for the simultaneous drying of multiple food samples, ensuring consistent quality and texture in the final product. - Environmental and Analytical Laboratories

Laboratories that perform soil, water, and air sample analyses also use freeze-drying to prepare samples for further examination. The ability to process multiple samples in parallel significantly enhances throughput in these environments. - Cosmetics

The cosmetics industry uses freeze-drying to preserve active ingredients in facial masks, serums, and other products. The multi-manifold dryer ensures that these ingredients retain their efficacy and stability over time.

Advantages of Multi-Manifold Vacuum Freeze Dryers

- Increased Efficiency

One of the primary advantages of using a Multi-Manifold Vacuum Freeze Dryer is the enhanced efficiency it offers. By processing multiple samples simultaneously, these systems reduce the time required for each drying cycle, allowing laboratories to increase throughput and meet production demands more effectively. - Improved Sample Quality

The precise control over vacuum and temperature conditions ensures that samples retain their original properties after freeze-drying. This is especially important for biological samples, where preserving cell structure and molecular integrity is crucial. - Cost-Effectiveness

Although the initial investment in a multi-manifold freeze dryer may be significant, the long-term benefits include lower operational costs due to reduced energy consumption and the ability to process larger volumes of material in less time. - Versatility

Multi-manifold systems are versatile and can be adapted to a wide range of applications, making them an excellent investment for research and industrial operations that require freeze-drying capabilities. - Enhanced Research Capabilities

For academic and commercial researchers, the ability to process a variety of samples simultaneously under optimized conditions opens up new possibilities for experimentation. The Multi-Manifold Vacuum Freeze Dryer helps researchers achieve more accurate results and enhance the reproducibility of their work.

The Multi-Manifold Vacuum Freeze Dryer is an indispensable tool for laboratories and industries involved in freeze-drying processes. Its advanced features, such as multiple manifolds, precise vacuum and temperature control, and energy efficiency, make it an ideal choice for high-throughput environments. Whether in pharmaceuticals, food processing, or environmental testing, this equipment ensures that materials are preserved under optimal conditions, maintaining their quality and integrity. The growing demand for freeze-drying systems, especially those with multi-manifold capabilities, highlights their importance in meeting the needs of modern laboratories and industries.

For more information on Multi-Manifold Vacuum Freeze Dryers, you can explore our product page or watch our video demonstration.