When choosing an overhead stirrer for your laboratory or industrial needs, understanding the power rating is essential. This simple yet crucial specification directly impacts your stirrer’s performance, energy consumption, and suitability for your specific applications. Whether you’re mixing liquids, suspending solids, or ensuring homogeneous solutions, the power rating is a key factor that determines how effectively the stirrer performs.

What is the Power Rating of an Overhead Stirrer?

The power rating of an overhead stirrer refers to the amount of electrical power the motor consumes to generate the mechanical force needed to drive the stirrer shaft. Typically expressed in watts (W) or horsepower (HP), the power rating indicates the capacity of the motor to handle different viscosities and the volume of the material being mixed. A higher power rating means the stirrer can mix thicker fluids or larger volumes more efficiently.

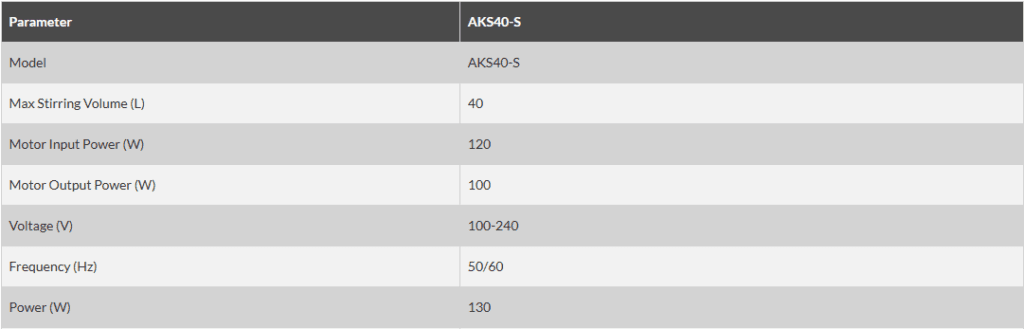

For example, the AKS40-S Electric Overhead Stirrer has a motor input power of 120W and a motor output power of 100W, with a total power consumption of 130W. It operates within a wide voltage range of 100-240V, making it suitable for use in different regions with varying power supply standards.

How Does Power Rating Affect Performance?

- Viscosity Handling: A higher power rating allows the stirrer to handle more viscous materials. If you’re working with thick solutions, suspensions, or emulsions, a stirrer with a higher power rating will provide more torque, ensuring smooth and continuous mixing without strain on the motor.

- Speed and Control: Power rating plays a crucial role in controlling the speed of the stirrer. While a higher power rating might offer more flexibility in terms of speed adjustments, it is important to note that not all processes require high-speed mixing. Choosing a stirrer with appropriate power ensures that you can achieve consistent results without overspending on energy.

- Capacity and Volume: The motor’s power also determines the maximum volume the stirrer can handle. Stirring large volumes of liquids or dense mixtures requires a motor that can maintain consistent speed and torque throughout the mixing process. A power rating too low for the required volume could lead to motor overheating or inconsistent mixing.

How Power Rating Influences Energy Efficiency

Energy efficiency is an important consideration when selecting an overhead stirrer. A more powerful stirrer may use more electricity, but if it’s suited to your application, it can reduce the need for prolonged mixing times, thereby optimizing energy use. On the other hand, a stirrer with too much power for a low-viscosity solution may waste energy, leading to unnecessary operational costs.

To find a stirrer that aligns with your needs, consider the specific tasks it will perform. For light applications like stirring low-viscosity liquids, a stirrer with a lower power rating may be more energy-efficient. For heavy-duty mixing of dense materials, investing in a higher power rating may be worthwhile, as it ensures faster and more efficient results.

Choosing the Right Overhead Stirrer Power Rating

The optimal power rating depends on several factors:

- Material Viscosity: Higher viscosity materials require more power to mix.

- Mixing Volume: Larger volumes demand stirrers with higher power ratings to maintain consistent mixing.

- Process Speed: If you require faster mixing, a more powerful stirrer may be necessary.

When selecting an overhead stirrer, it’s essential to match the power rating to your specific mixing requirements. Overestimating the power rating may lead to higher energy costs, while underestimating it could result in insufficient mixing and poor process outcomes.

Understanding the power rating of overhead stirrers is key to selecting the right equipment for your lab or industrial process. By considering factors such as viscosity, volume, and required mixing speed, you can choose a stirrer that offers the best balance between performance and energy efficiency. Ensuring your stirrer’s power rating aligns with your needs will help you achieve efficient, reliable results while minimizing unnecessary energy consumption.

For more detailed information on choosing the right overhead stirrer for your application, check out the AKS40-S Electric Overhead Stirrer!