In chemical laboratories and industrial settings, mixing is a crucial step in ensuring the uniformity and consistency of chemical reactions. For precise and reliable mixing, overhead stirrers for chemicals are an indispensable tool. These stirrers are designed to handle a variety of chemical processes, including those that involve viscous liquids, powders, and other complex substances. This article will help you understand how overhead stirrers work in chemical processes and guide you on selecting the best models for your needs.

1. Why Overhead Stirrers are Essential for Chemical Processes

Chemical reactions often require precise control over mixing conditions to ensure optimal results. Standard magnetic stirrers may not provide enough power or control for many chemical processes, especially when dealing with high-viscosity liquids, solid-liquid mixtures, or reactions requiring prolonged stirring.

An overhead stirrer for chemicals is equipped with a motor and a rotating shaft that can handle much more demanding tasks. These stirrers are ideal for mixing heavy liquids, suspensions, or emulsions, as well as for high-temperature and high-pressure reactions. The ability to adjust speed and torque ensures that the stirrer can accommodate a range of substances and process requirements.

2. Key Features of Overhead Stirrers for Chemical Processes

When selecting an overhead stirrer for chemicals, there are several important features to consider to ensure that it meets your specific laboratory or industrial needs:

- High Torque Capacity: Chemical processes often involve thicker materials or require higher torque to achieve uniform mixing. Look for stirrers with powerful motors that can handle demanding tasks without stalling.

- Adjustable Speed and Torque: Different chemicals and processes require different mixing speeds. The best overhead stirrers for chemicals allow you to adjust both speed and torque, giving you the flexibility to control the mixing process and optimize results.

- Corrosion-Resistant Materials: Many chemicals, especially acids, bases, and solvents, can be corrosive. Choose overhead stirrers made from corrosion-resistant materials like stainless steel or other durable alloys to ensure longevity and reliability.

- Safety Features: Overhead stirrers used in chemical processes often involve high temperatures or hazardous chemicals. Look for models with built-in safety features, such as overload protection, temperature monitoring, and explosion-proof designs.

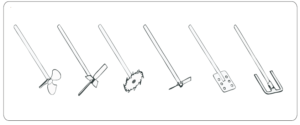

- Versatile Mixing Attachments: Depending on the chemical process, you may need different types of mixing attachments, such as paddle blades, propellers, or stir shafts. The best stirrers offer interchangeable mixing heads to accommodate various applications.

3. Types of Overhead Stirrers for Chemical Applications

There are several types of overhead stirrers for chemicals available, each designed for specific types of chemical processes. Here are some popular models:

- Digital Overhead Stirrer for Chemicals

Digital overhead stirrers are ideal for precise mixing in chemical processes. Equipped with a digital display and control system, they allow you to monitor and adjust mixing speed, time, and torque with accuracy. These stirrers are commonly used in laboratories where precision and repeatability are required for chemical reactions.

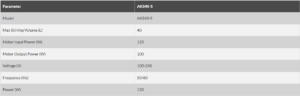

Check out the AKS20-U Digital Overhead Stirrer here. - High Torque Overhead Stirrer

For particularly thick or dense chemical mixtures, a high-torque overhead stirrer is essential. These models provide the power needed to mix heavy suspensions, emulsions, and other high-viscosity materials. They are perfect for use in the chemical, pharmaceutical, and food industries. - Explosion-Proof Overhead Stirrer

In certain chemical processes, such as when mixing volatile or flammable chemicals, safety is paramount. Explosion-proof overhead stirrers are designed to operate safely in hazardous environments, preventing sparks or electrical issues that could lead to accidents.

4. Applications of Overhead Stirrers in Chemical Processes

Overhead stirrers for chemicals are versatile and used in various chemical processes across industries. Some common applications include:

- Pharmaceutical Manufacturing: In pharmaceutical labs, overhead stirrers are used to mix active pharmaceutical ingredients (APIs) with excipients, as well as in emulsification and homogenization processes for creams, gels, and suspensions.

- Chemical Synthesis: Many chemical synthesis reactions, including polymerization, crystallization, and precipitation, require continuous stirring to ensure a uniform reaction rate. Overhead stirrers provide the necessary power and control to maintain a steady and efficient reaction.

- Paint and Coatings: In the paint and coatings industry, overhead stirrers for chemicals are used to mix pigments, resins, and solvents to create smooth, uniform paints, varnishes, and coatings.

- Food and Beverage Industry: Overhead stirrers are also used in food processing for the creation of emulsions, sauces, dressings, and other viscous food products.

- Environmental and Water Treatment: For the treatment of wastewater or environmental samples, overhead stirrers can help mix chemicals such as flocculants, disinfectants, and other treatment agents to ensure effective treatment.

5. Choosing the Right Overhead Stirrer for Chemical Processes

When choosing an overhead stirrer for chemicals, it’s important to consider the following factors:

- Viscosity of the Chemicals: Select a stirrer with the appropriate torque and mixing speed for the specific viscosity of the chemicals you are working with.

- Container Size: Ensure the stirrer can handle the volume of material you need to mix, whether it’s in small laboratory glassware or large industrial vats.

- Chemical Compatibility: Consider the materials of construction for the stirrer, ensuring they are compatible with the chemicals being used in your process.

- Temperature and Pressure Requirements: If your chemical process involves high temperatures or pressures, choose a stirrer that can withstand these conditions safely.

6. Watch the Overhead Stirrer in Action

Want to see how overhead stirrers for chemicals perform in real-world chemical processes? Check out this demonstration video on YouTube to see the stirrers in action.

For chemical processes that demand reliable and consistent mixing, choosing the right overhead stirrer for chemicals is essential. These stirrers provide the power, precision, and versatility needed to ensure the success of chemical reactions in laboratories and industrial settings. Whether you are mixing pharmaceutical ingredients, chemicals for synthesis, or coatings and paints, overhead stirrers are critical tools for achieving uniformity and consistency in your chemical processes.

To find the right overhead stirrer for your chemical applications, explore our range of overhead stirrers for chemicals.