In laboratories and industrial settings, achieving uniform consistency in mixtures is crucial for accurate results, especially in homogenization processes. Whether you are working with emulsions, suspensions, or complex liquid formulations, overhead stirrers for homogenization are the go-to tools for ensuring that every ingredient is evenly distributed. This article will explore how overhead stirrers excel in homogenizing substances and why they are indispensable for maintaining consistent results in your processes.

What is Homogenization?

Homogenization is the process of creating a uniform mixture by breaking down substances into smaller particles. In chemical, pharmaceutical, and food industries, this is an essential step to ensure that the final product is consistent in texture, appearance, and performance. For instance, in pharmaceuticals, it is important that active ingredients are evenly distributed, while in food production, the texture of sauces or dressings needs to remain smooth and consistent.

While simple mixing may suffice for some applications, overhead stirrers for homogenization offer the precision and power necessary for achieving the fine, even dispersion required in more complex processes.

How Overhead Stirrers Improve Homogenization

Overhead stirrers for homogenization are specifically designed to handle high shear forces, which are essential for breaking down particles and ensuring even distribution in viscous materials. Here’s how these stirrers improve the homogenization process:

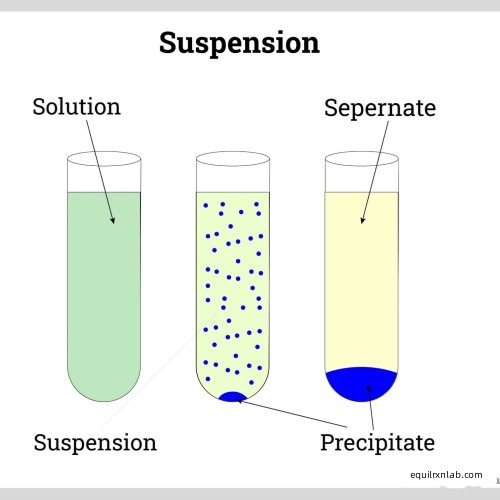

- High Shear Mixing: Overhead stirrers use powerful motors and adjustable speeds to generate high shear forces, which effectively break down larger particles into smaller, uniform sizes. This is especially important for creating emulsions, suspensions, and gels that require fine, even mixing.

- Consistent Results: With adjustable speed and torque, overhead stirrers ensure that the substance is evenly mixed from top to bottom. This level of control is particularly useful when working with high-viscosity materials, where uniformity can be difficult to achieve with lower-powered equipment.

- Versatility in Mixing: Depending on the type of homogenization required, different stirring heads can be used. Paddle blades, propellers, or rotor-stator heads can all be attached to overhead stirrers to suit specific homogenization tasks. This versatility ensures that the stirrer can adapt to different materials and process requirements.

- Reduced Time and Effort: Using an overhead stirrer with adjustable speeds and torque allows for faster homogenization. You can achieve the same level of consistency with less effort and in less time compared to manual stirring or other mixing methods.

Applications of Overhead Stirrers in Homogenization

The applications of overhead stirrers for homogenization span across various industries, where uniformity is key. Some common applications include:

- Pharmaceuticals: In drug formulations, overhead stirrers are used to homogenize active pharmaceutical ingredients (APIs) and excipients to ensure even dispersion and uniform consistency in the final product.

- Food and Beverages: Overhead stirrers play a vital role in creating smooth, consistent textures in food products like sauces, dressings, dairy products, and beverages. They help in emulsifying oils and water-based ingredients, resulting in uniform products.

- Cosmetics and Personal Care: Homogenization is essential in creating stable emulsions for creams, lotions, and ointments. Overhead stirrers ensure that ingredients are evenly mixed, providing consistent product quality.

- Chemical Industry: In the production of coatings, paints, and adhesives, overhead stirrers are used to homogenize pigments and chemicals, ensuring uniformity in color and consistency across large batches.

Why Choose Overhead Stirrers for Homogenization?

There are several reasons why overhead stirrers are a better choice for homogenization compared to traditional mixing methods:

- Powerful and Efficient: With motors that offer high torque, overhead stirrers provide the necessary power to process thicker, more viscous substances that require more force to mix thoroughly.

- Accuracy and Precision: The ability to adjust the speed and torque allows you to fine-tune the mixing process to meet your exact requirements. Whether you need slow mixing for gentle emulsification or high-speed shear for dispersion, overhead stirrers give you precise control over the process.

- Safety and Reliability: Overhead stirrers are built to handle tough materials and high temperatures safely, reducing the risk of accidents and downtime. Their robust construction ensures longevity and reliability in continuous processes.

- Ease of Use: Many modern overhead stirrers for homogenization come with digital interfaces that allow for easy control and monitoring of parameters, making them user-friendly and efficient.

Recommended Overhead Stirrer for Homogenization

If you’re looking for a reliable overhead stirrer for homogenization, consider the AKS40-S Electric Overhead Stirrer. This model offers precise control over speed and torque, making it ideal for high-shear mixing applications. With a robust design and advanced features, it ensures efficient and consistent homogenization results, whether in pharmaceutical, food, or chemical processes.

Overhead stirrers are essential tools for achieving efficient and precise homogenization. By providing high shear mixing, adjustable speeds, and versatile attachments, these stirrers ensure that substances are evenly mixed, improving the consistency and quality of your final product. Whether you’re working with pharmaceuticals, food products, or chemicals, investing in a reliable overhead stirrer will optimize your homogenization process and improve your results.

For more details on overhead stirrers for your homogenization needs, check out the AKS40-S Electric Overhead Stirrer.

Watch the Product in Action

Check out this video for a demonstration of how the AKS40-S Electric Overhead Stirrer works in action: Watch on YouTube.