Detailed Description

Product Overview

The A-Type glass molecular distillation unit is a lab-scale short-path distillation system developed for the purification and separation of high-boiling and heat-sensitive compounds under high vacuum conditions. By minimizing the distance between the evaporation surface and the condenser, the system reduces thermal degradation while improving separation efficiency.

This molecular distillation equipment is widely applied in essential oil refining, plant oil purification, botanical extraction research, and pharmaceutical process development.

Typical Applications

Essential oil concentration and purification

Plant oil and botanical extract refinement

Separation of heat-sensitive and high-boiling compounds

Laboratory research and formulation development

Small pilot-scale molecular distillation testing

Key Features

Short-path evaporation structure

Reduces residence time and thermal stress, suitable for sensitive materials.High-transparency glass construction

Provides excellent chemical resistance and full visual observation during operation.Adjustable processing capacity

Feed rates from 0.1 kg/h up to 15.0 kg/h, depending on the model.Stable motor-driven wiped film system

Ensures uniform material distribution and consistent evaporation performance.Efficient condensation surfaces

Condensation areas range from 0.1 m² to 0.65 m², maximizing product recovery.Constant-pressure feeding funnel (1.5 L)

Enables smooth and accurate material feeding under vacuum conditions.

Model Range & Technical Specifications

FMD-60(A)

Evaporation Area: 0.05 m²

Condensation Area: 0.1 m²

Vessel Inner Diameter: 60 mm

Funnel Capacity: 1.5 L

Processing Flow: 0.1–2.0 kg/h

Motor Power: 120 W

Maximum Speed: 450 RPM

Recommended for initial laboratory research and small-batch molecular distillation trials.

FMD-80(A)

Evaporation Area: 0.1 m²

Condensation Area: 0.15 m²

Vessel Inner Diameter: 80 mm

Funnel Capacity: 1.5 L

Processing Flow: 0.3–4.0 kg/h

Motor Power: 120 W

Maximum Speed: 450 RPM

Suitable for routine laboratory distillation and R&D applications.

FMD-100(A)

Evaporation Area: 0.15 m²

Condensation Area: 0.2 m²

Vessel Inner Diameter: 100 mm

Funnel Capacity: 1.5 L

Processing Flow: 0.5–5.0 kg/h

Motor Power: 120 W

Maximum Speed: 450 RPM

Balanced capacity for laboratory-scale molecular distillation processes.

FMD-150(A)

Evaporation Area: 0.25 m²

Condensation Area: 0.4 m²

Vessel Inner Diameter: 150 mm

Funnel Capacity: 1.5 L

Processing Flow: 1.0–8.0 kg/h

Motor Power: 120 W

Maximum Speed: 450 RPM

Higher throughput option for advanced laboratory applications.

FMD-200(A)

Evaporation Area: 0.35 m²

Condensation Area: 0.5 m²

Vessel Inner Diameter: 190 mm

Funnel Capacity: 1.5 L

Processing Flow: 1.5–10.0 kg/h

Motor Power: 200 W

Maximum Speed: 300 RPM

Optimized for pilot-scale molecular distillation validation.

FMD-230(A)

Evaporation Area: 0.5 m²

Condensation Area: 0.65 m²

Vessel Inner Diameter: 220 mm

Funnel Capacity: 1.5 L

Processing Flow: 2.0–15.0 kg/h

Motor Power: 200 W

Maximum Speed: 300 RPM

Professional-grade system for continuous laboratory operation.

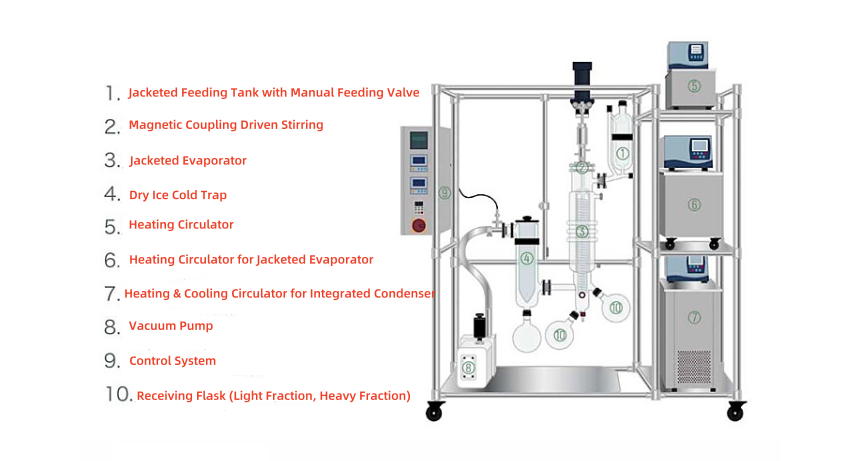

Compatible Auxiliary Equipment

For optimal performance, the glass molecular distillation unit can be integrated with:

High-vacuum pumps (rotary vane or diffusion pump systems)

Heating circulators for precise temperature control

Fraction collectors for multi-stage separation

Mechanical stirring systems

Pre-filtration units for raw material preparation

Key Advantages

Designed for laboratory and small pilot-scale use

Excellent performance for heat-sensitive materials

Gentle evaporation with high product recovery

Modular configuration for flexible process optimization

Reliable and reproducible molecular distillation results

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | Effective Evaporation Area (M²) | Condensation Area (M²) | Body Inner Diameter (mm) | Feeding Funnel Capacity (L) | Processing Capacity (KG/H) | Motor Power (W) | Max Rotation Speed (RPM) |

|---|---|---|---|---|---|---|---|

| FMD-60(A) | 0.05 | 0.1 | 60 | 1.5 | 0.1–2.0 | 120 | 450 |

| FMD-80(A) | 0.1 | 0.15 | 80 | 1.5 | 0.3–4.0 | 120 | 450 |

| FMD-100(A) | 0.15 | 0.2 | 100 | 1.5 | 0.5–5.0 | 120 | 450 |

| FMD-150(A) | 0.25 | 0.4 | 150 | 2 | 1.0–8.0 | 120 | 450 |

| FMD-200(A) | 0.35 | 0.5 | 190 | 2 | 1.5–10.0 | 200 | 300 |

| FMD-230(A) | 0.5 | 0.65 | 220 | 2 | 2.0–15.0 | 200 | 300 |

introduce

Application Scenarios

Laboratory research: Perform precise Short-Path Molecular Distillation for heat-sensitive compounds and high-purity chemical separation.

Essential oil extraction: Efficiently extract and purify essential oils and plant oils using reliable Short-Path Molecular Distillation techniques.

Pharmaceutical development: Produce small-scale active ingredients and purified compounds with Short-Path Molecular Distillation units.

Educational labs: Demonstrate chemical separation processes and molecular distillation principles in a controlled, visible environment.

Small-scale production: Ideal for boutique or pilot-scale production requiring consistent and reproducible Short-Path Molecular Distillation results.

peculiarity