Detailed Description

Key Features

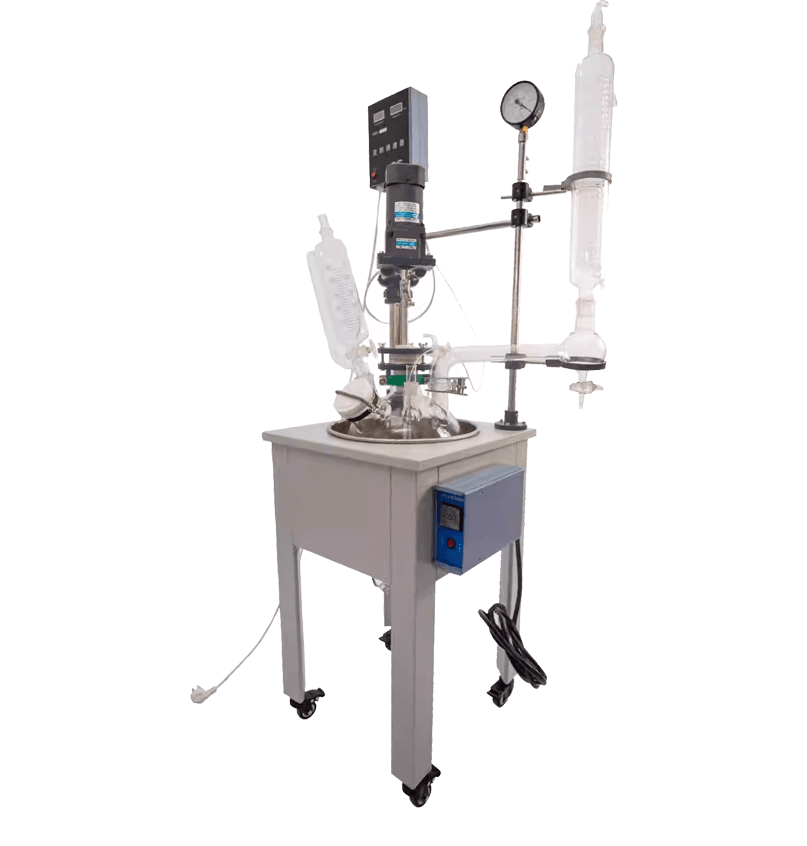

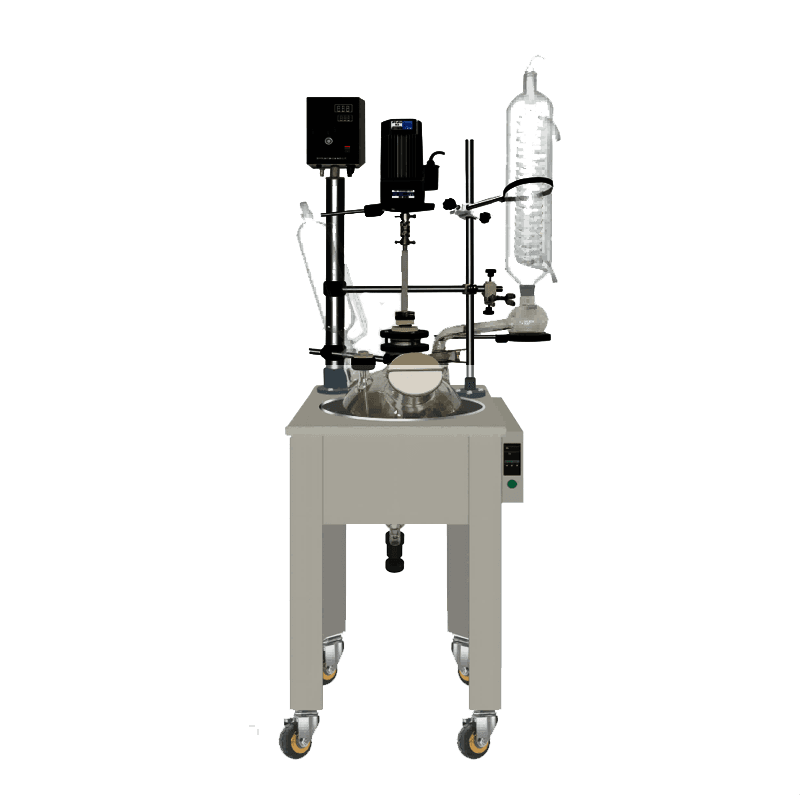

Large 20L capacity barrel-type vessel designed for the Electric Heating Single Layer Glass Reactor.

Powerful 4.0 kW electric heating system integrated into the Electric Heating Single Layer Glass Reactor for rapid and uniform heating.

Digital temperature control of the Electric Heating Single Layer Glass Reactor offers precise adjustments between room temperature and 200°C.

Stainless steel fluorine-coated paddle with weldless integration designed specifically for the Electric Heating Single Layer Glass Reactor to enhance corrosion resistance.

Adjustable stirring speed from 0 to 450 rpm for versatile mixing in the Electric Heating Single Layer Glass Reactor.

Equipped with a 2000 ml constant pressure funnel and a 125 mm solid feeding port to support varied inputs in the Electric Heating Single Layer Glass Reactor.

Optional cooling coil, explosion-proof motor, and insulation layer to optimize the Electric Heating Single Layer Glass Reactor for safety and efficiency.

Frame-type rack structure provides sturdy support for the Electric Heating Single Layer Glass Reactor operation.

Technical Specifications

Material Capacity: 20 L

Vessel Type: Barrel type (Optional)

Stirring Paddle: Stainless steel with fluorine coating, integrated paddle (weldless)

Rotational Speed: 0–450 rpm

Motor Power: 120 W

Heating Power: 4.0 kW

Temperature Control: Digital

Temperature Range: Room temperature to 200°C

Control Accuracy: ±1°C

Constant Pressure Funnel: 2000 ml

Solid Feeding Port: 125 mm

Cooling Coil: Optional

Rack Type: Frame type

Explosion-proof Motor: Optional

Insulation Layer: Optional

Power Supply: 220V / 50Hz

Compatible Equipment

Magnetic stirrer to enhance stirring precision for Electric Heating Single Layer Glass Reactor applications.

Vacuum pump for enabling vacuum distillation with the Electric Heating Single Layer Glass Reactor.

Temperature circulator to maintain stable temperatures with the Electric Heating Single Layer Glass Reactor cooling coil option.

Reflux condenser for efficient vapor condensation during reactions in the Electric Heating Single Layer Glass Reactor.

Explosion-proof valve to ensure safety when using the Electric Heating Single Layer Glass Reactor in volatile processes.

Emphasized Advantages

The Electric Heating Single Layer Glass Reactor delivers unmatched precision, safety, and durability. Its 4.0 kW electric heating system combined with digital temperature control ensures reliable and efficient performance. Optional explosion-proof motor and insulation provide enhanced safety. The barrel-type vessel and fluorine-coated paddle guarantee long-lasting corrosion resistance, making the Electric Heating Single Layer Glass Reactor perfect for demanding chemical reactions at laboratory and pilot scales.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Cooling Solutions

Discover more advanced models and solutions in our Single Layer Glass Reactor category.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKDF-10L | AKDF-20L | AKDF-30L | AKDF-50L | AKDF-100L |

|---|---|---|---|---|---|

| Material Capacity (L) | 10 | 20 | 30 | 50 | 100 |

| Vessel Type | Barrel type (Optional) | ||||

| Stirring Paddle | Stainless steel with fluorine material, integrated paddle-weldless | ||||

| Rotational Speed (rpm) | 0-450 | ||||

| Motor Power (W) | 120 | 120 | 120 | 120 | 120 |

| Heating Power (KW) | 3 | 4 | 5 | 6 | 9 |

| Temperature Control | Digital temperature control | ||||

| Temperature Range (°C) | Room temperature to 200°C | ||||

| Control Accuracy | ±1°C | ||||

| Constant Pressure Funnel (ml) | 1000 | 2000 | |||

| Solid Feeding Port (mm) | 125 | ||||

| Cooling Coil | Optional | ||||

| Rack Type | Frame type | ||||

| Explosion-proof Motor | Optional | ||||

| Insulation Layer | Optional | ||||

| Power Supply | 220V/50Hz | 380V/50Hz | |||

introduce

Application Scenarios

Pharmaceutical Intermediate Synthesis

The Electric Heating Single Layer Glass Reactor is ideal for synthesizing pharmaceutical intermediates that require precise temperature control and stable agitation during long reaction cycles.Organic Chemistry Experiments

In organic laboratories, this reactor supports controlled heating up to 200°C, making it suitable for various reflux, distillation, and condensation experiments.Pilot-Scale Process Development

With a 20L capacity, it bridges the gap between laboratory research and industrial production, making it a reliable tool for pilot-scale reaction validation.Natural Product Extraction and Purification

The system provides controlled thermal conditions to extract and purify active compounds from botanical or marine sources, enhancing efficiency and repeatability.Material Science and Polymer Research

The reactor is widely used for polymerization, resin synthesis, and composite material development where temperature stability and mechanical stirring are essential.Academic and Teaching Laboratories

Due to its visibility and operational simplicity, it is commonly employed in university labs for demonstration and research training in chemical engineering and applied chemistry.

peculiarity

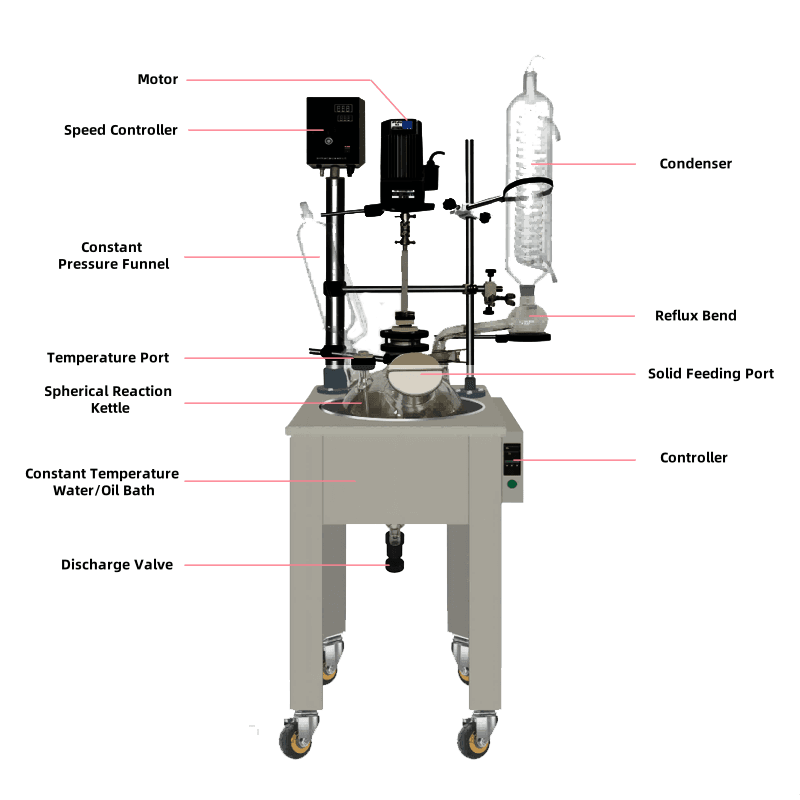

Full Copper Brushless Motor

Pure Copper Motor Coil, High Torque at Low Speed, Stepless Speed Regulation, Low Noise, Long Lifespan

Spiral Condenser

The inner tube is spiral-shaped, providing a larger cooling surface area for more effective condensation

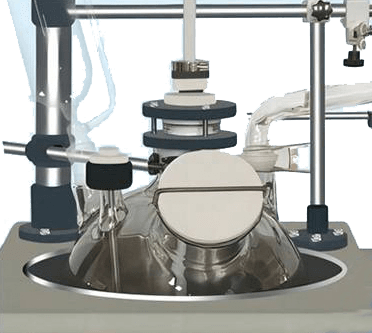

Sealing Device

Constructed from PTFE with CNC precision, featuring stainless steel bearings and fluororubber seals for resistance to acidic and alkaline gases. Reinforced with a plastic-coated aluminum flange to ensure stable stirring without tilting or wobbling.

Stainless Steel Pot Chamber

High Borosilicate Glass Parts in Contact with Materials Made from High Borosilicate Glass and PTFE (Polytetrafluoroethylene), Stable Performance with Minimal Chemical Reaction with Materials

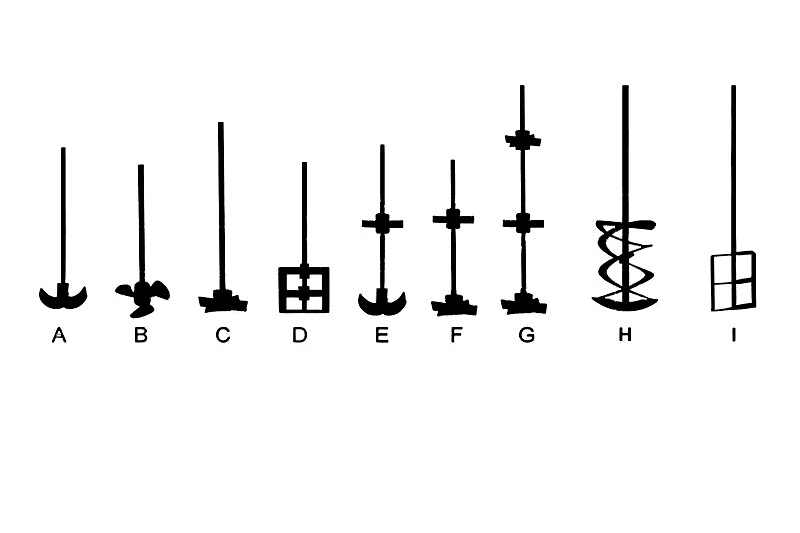

Multiple stirring paddles available for your selection

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well