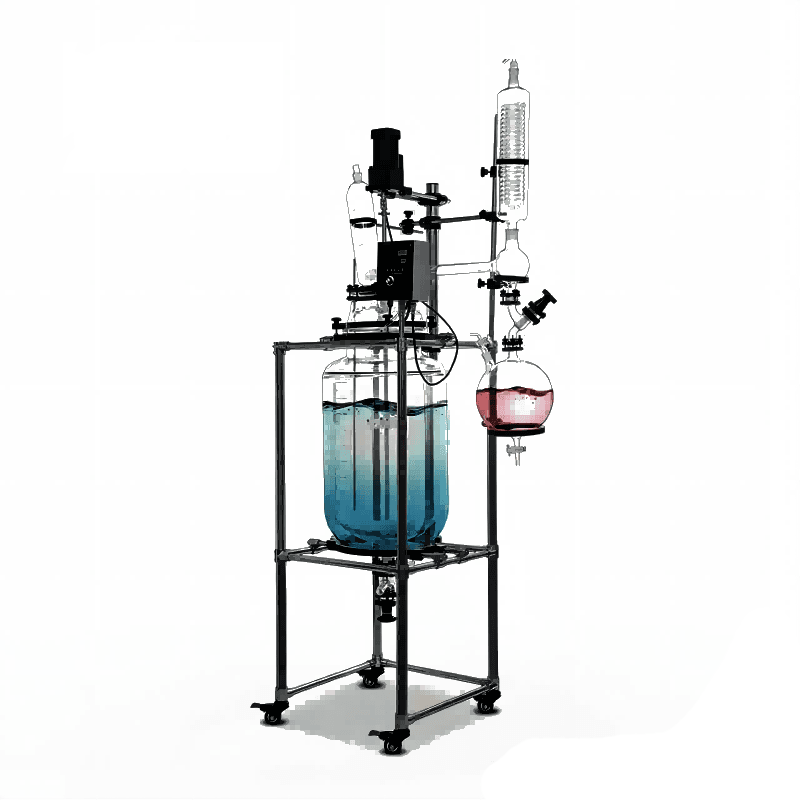

AKF-100L double-glazed reactor

AKF-100L Double-Glazed Reactor: High-Capacity, Precision, and Versatility for Industrial Applications

The AKF-100L Double-Glazed Reactor is the perfect solution for large-scale chemical synthesis, distillation, and extraction processes. With a robust 100L material capacity and 60L jacket capacity, this double-glazed reactor offers exceptional thermal control for high-volume reactions, whether they require cryogenic or high-temperature conditions. Operating within a temperature range of -120°C to 300°C, the reactor provides flexible, efficient, and precise temperature management for a wide variety of industrial and laboratory applications.

Designed for both industrial-scale processes and advanced laboratory use, the AKF-100L double-glazed reactor boasts a fluorine-coated stainless steel stirrer for smooth and consistent mixing. With 6 customizable ports, it can accommodate various setups and requirements, making it a highly adaptable reactor for different chemical operations. Whether you need precise temperature control, reliable stirring, or safety features like explosion-proof motors, the AKF-100L double-glazed reactor delivers on all fronts.

Key Features & Specifications

- Material Capacity: 100 liters

- Jacket Capacity: 60 liters

- Temperature Range: -120°C to 300°C

- Number of Ports: 6 customizable ports

- Constant Pressure Funnel: 5 liters

- Stirring Mechanism: Stainless steel fluorine-coated stirrer

- Reactor Dimensions:

- Cover Diameter: 600 mm

- Inner Cylinder Diameter: 500 mm

- Outer Cylinder Diameter: 600 mm

- Vessel Height: 1070 mm

- Speed Range: 0-450 rpm

- Stirring Shaft Diameter: 20 mm

- Stirring Connection: Universal joint connection

- Voltage Frequency: 220V/50Hz

- Temperature Probe: PT100 sensor

- Explosion-Proof Control Box: Optional

- Insulating Jacket: Optional

- Explosion-Proof Motor: Optional

Why Choose the AKF-100L Double-Glazed Reactor?

- Massive Capacity for Large-Scale Processes: The AKF-100L double-glazed reactor offers an impressive 100L material capacity and 60L jacket capacity, making it ideal for high-volume chemical reactions in both industrial and laboratory settings.

- Versatile Temperature Control: With a wide temperature range from -120°C to 300°C, this reactor is perfect for reactions that require either cryogenic or high-heat conditions, offering precise control over reaction environments.

- Efficient Stirring for Consistency: The fluorine-coated stainless steel stirrer ensures smooth, reliable mixing, even at lower speeds (up to 450 rpm), preventing uneven reactions and ensuring high-quality results.

- Customizable Ports for Flexibility: The 6 customizable ports give you the ability to configure the reactor to meet your specific process requirements, making it suitable for various chemical operations.

- Optional Safety Features: The AKF-100L double-glazed reactor offers optional explosion-proof motors and control boxes, ensuring that your processes are safe even in volatile environments.

Product specifications

| Model | AKF-1L | AKF-2L | AKF-3L | AKF-5L | AKF-10L | AKF-20L | AKF-30L | AKF-50L | AKF-100L | AKF-150L | AKF-200L |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material Capacity (L) | 1L | 2L | 3L | 5L | 10L | 20L | 30L | 50L | 100L | 150L | 200L |

| Mezzanine Capacity (L) | 1 | 1.5 | 2 | 2 | 6 | 10 | 16 | 30 | 60 | 60 | 60 |

| Number of Ports | 5 (Customizable) | 6 (Customizable) | |||||||||

| Constant Pressure Funnel | 250ML | 500ML | 1L | 2L | 5L | ||||||

| Stirring Paddle | Stainless Steel Covered with Fluorine Material | ||||||||||

| coverage diameter (mm) | 150 | 190 | 200 | 260 | 340 | ||||||

| inner cylinder diameter (mm) | 100 | 150 | 170 | 220 | 290 | 340 | |||||

| outer cylinder diameter (mm) | 150 | 170 | 200 | 230 | 270 | 370 | 410 | 500 | 600 | 690 | |

| vessel height (mm) | 320 | 370 | 395 | 430 | 500 | 635 | 710 | 820 | 1070 | 1170 | 1280 |

| Rotational Speed (rpm) | 0-1350 | 0-450 | |||||||||

| Stirring Shaft Diameter (mm) | 8 | 15 | 17 | ||||||||

| Stirring Connection | Gimbal Connection | ||||||||||

| Voltage Frequency | 220V/50Hz | ||||||||||

| temperature range | Low -120°C to High 300°C | ||||||||||

| Temperature Probes | PT100 Sensor Probe | ||||||||||

| Explosion-proof Control Box | Optional | ||||||||||

| Insulated Clothing | Optional | ||||||||||

| explosion-proof motor | Optional | ||||||||||

introduce

Product features:

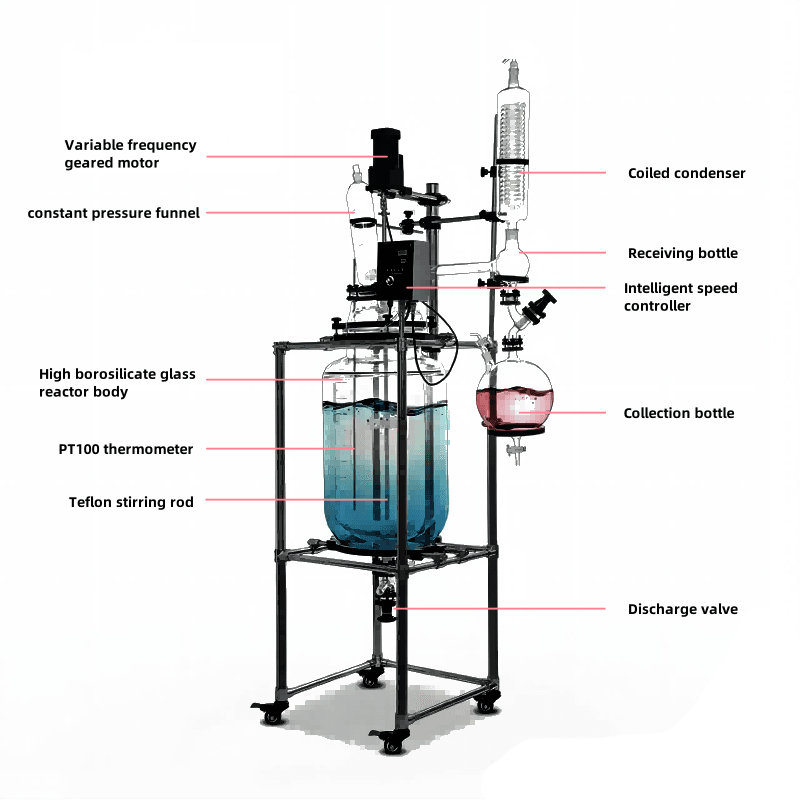

1. The parts in contact with the material are all made of high borosilicate glass (expansion system

No. 3.3) and PTFE materials, stable performance is not easy with materials

It is chemically reactive and easy to use.

2.The main bracket is made of cold plate anti-corrosion spraying + aluminum alloy material

Strong anti-corrosion, anti-oxidation characteristics, the pot is made of stainless steel

Quality, compact structure, durable, beautiful appearance.

3. Stirring and heating power on/off control, tilting button

(ON-OFF), simple and easy to operate.

4. Electronic stepless speed regulation, through the twist fine-tuning, the speed box digital display

Indication speed, stable performance, easy to use.

5. Digital display of thermostatic bath temperature, K-type sensor at the bottom of the pot + stainless steel

Probes make temperature control more accurate, and transfer temperature quickly and accurately.

6. The stirring system adopts ceramic bearings and mechanical seals to prevent stirring

The mixing rod is worn and debrated, with high temperature resistance, wear resistance and good sealing effect.

7. Vacuum pressure gauge shows real-time vacuum, pointer display.

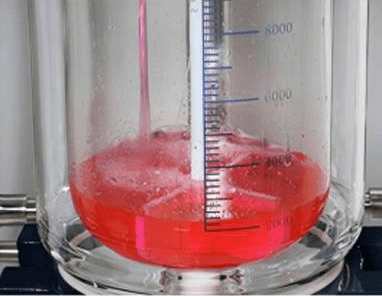

8. Crescent stirring paddle, 304 stainless steel + PTFE stirring

Leaf; The stirring rod is made of 304 stainless steel outer PTFE pipe,

High strength and strong corrosion resistance.

9. Stirring and heating double fuse* high protection performance.

peculiarity

Bottom Discharge Port

High borosilicate glass, anti-corrosion and corrosion-resistant

Spiral condenser

Inner tube spiral, cooling area Large, more effective condensation

High borosilicate glass

Corrosion-resistant,High temperature resistance 300'C, high borosilicate The glass has a low expansion rate and is resistant to high

PTFE stir bar

PTFE impeller is corrosion-resistant Corrosion/acid and alkali resistance

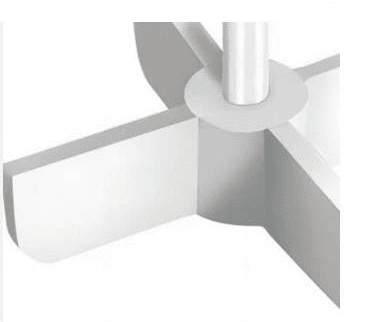

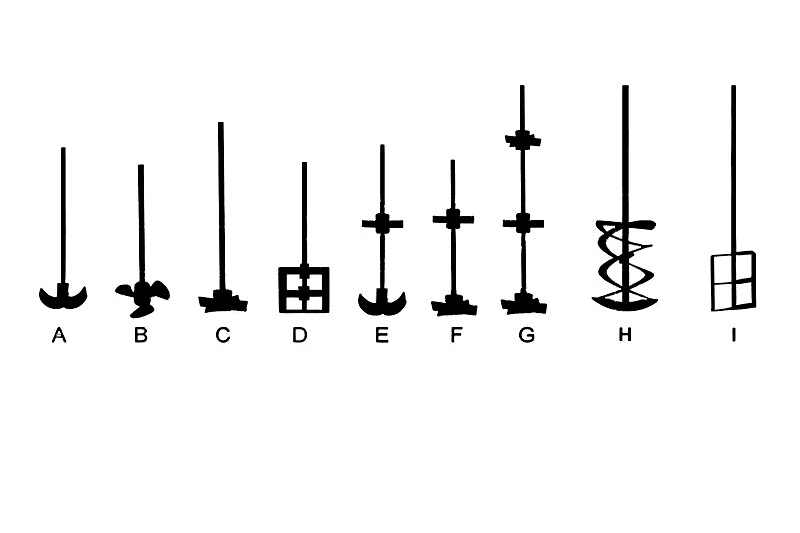

Multiple stirring paddles available for your selection

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well

Scope of Application

Biopharmaceuticals

Scientific Research Experiments

Food Processing

industrial factory

Why choose us?

Factory direct sales

“Factory direct sales ensure affordability, reliability, and direct access to high-quality products.”

Reliable quality

“Reliable quality ensures trust, satisfaction, durability, and consistent performance.”

Worry free after sale

“Worry-free after-sale service ensures peace of mind and satisfaction.”

Customized service

“Customized services provide personalized solutions and tailored experiences.”