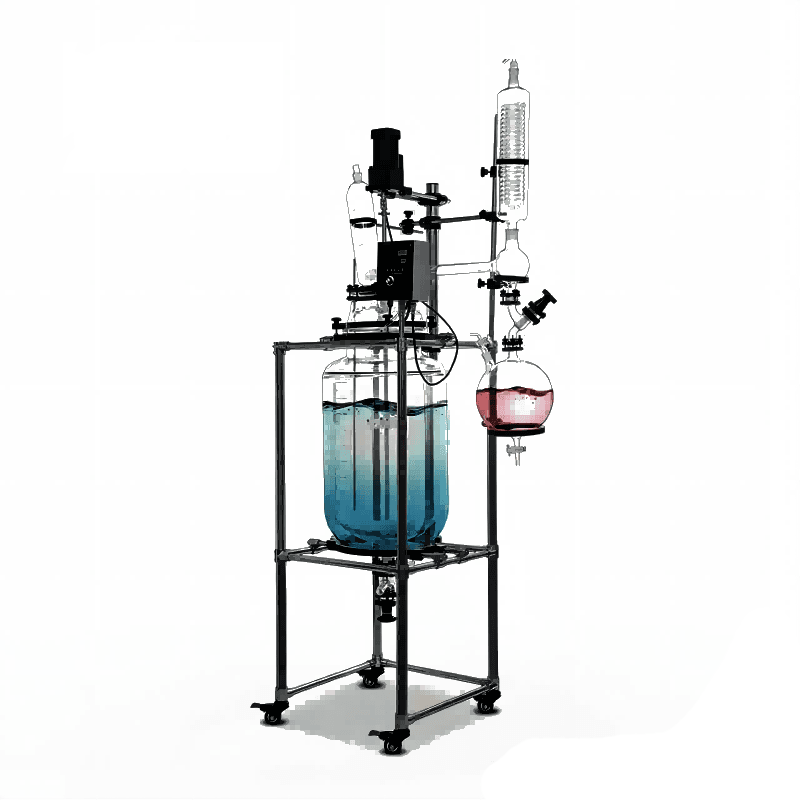

Detailed Description

Key Features of the Double Layer Reactor

High Capacity: 20L inner vessel for materials and 10L mezzanine layer for circulation fluids.

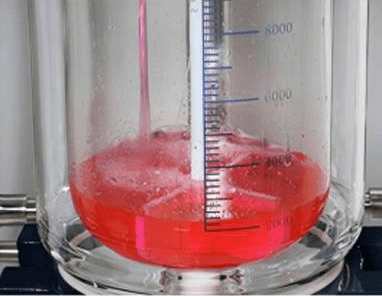

Efficient Heat Exchange: Double layer glass structure enables rapid heating or cooling.

Robust Stirring: Stainless steel stirring paddle coated with fluorine for chemical resistance.

Customizable Design: Six ports on the reactor lid allow for multiple functional expansions.

Wide Temperature Range: Suitable for both cryogenic and high-temperature reactions.

Durable Construction: Precision borosilicate glass, corrosion-resistant materials, and a gimbal stirring connection.

Technical Specifications

Material Capacity: 20L

Mezzanine Capacity: 10L

Number of Ports: 6 (Customizable)

Constant Pressure Funnel: 1L

Stirring Paddle: Stainless Steel Covered with Fluorine Material

Coverage Diameter: 260 mm

Inner Cylinder Diameter: 220 mm

Outer Cylinder Diameter: 370 mm

Vessel Height: 635 mm

Rotational Speed: 0–450 rpm

Stirring Shaft Diameter: 15 mm

Voltage / Frequency: 220V / 50Hz

Temperature Range: -120°C to +300°C

Compatible Equipment Suggestions

Recirculating Chiller: Provides stable low-temperature fluid for the mezzanine jacket.

Heating Circulator: Supports precise high-temperature applications up to 300°C.

Vacuum Pump: Enables reduced-pressure reactions and solvent removal.

Reflux Condenser: Useful in distillation and reflux applications under controlled conditions.

Temperature Controller: Ensures high-accuracy PID temperature regulation across the process.

Performance Highlight

The Double Layer Reactor 20L stands out for its combination of capacity, stability, and adaptability. Its double-walled design ensures highly efficient thermal exchange, while the chemical-resistant fluorine-coated paddle guarantees consistent mixing. Whether used in pharmaceutical R&D, chemical synthesis, or material science labs, this Double Layer Reactor offers reliability and versatility for a wide range of professional applications.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More

Explore our full range of Double Layer Reactor models on the double glass reactor category page.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKF-10L | AKF-20L | AKF-30L | AKF-50L | AKF-100L | AKF-150L | AKF-200L |

|---|---|---|---|---|---|---|---|

| Material Capacity (L) | 10L | 20L | 30L | 50L | 100L | 150L | 200L |

| Mezzanine Capacity (L) | 6 | 10 | 16 | 30 | 60 | ||

| Number of Ports | 6 (Customizable) | ||||||

| Constant Pressure Funnel | 1L | 2L | 5L | ||||

| Stirring Paddle | Stainless Steel Covered with Fluorine Material | ||||||

| Coverage Diameter (mm) | 260 | 340 | |||||

| Inner Cylinder Diameter (mm) | 220 | 290 | 340 | ||||

| Outer Cylinder Diameter (mm) | 270 | 370 | 410 | 500 | 600 | 690 | |

| Vessel Height (mm) | 500 | 635 | 710 | 820 | 1070 | 1170 | 1280 |

| Rotational Speed (rpm) | 0-450 | 0-450 | 0-450 | 0-400 | 0-350 | 0-300 | 0-250 |

| Stirring Shaft Diameter (mm) | 15 | 15 | 15 | 17 | 20 | 22 | 25 |

| Voltage Frequency | 220V/50Hz | ||||||

| Temperature Range | Low -120°C to High 300°C | ||||||

introduce

Application Scenarios

Chemical Synthesis and Reaction Optimization

The Double Layer Reactor is ideal for complex organic or inorganic synthesis that requires accurate temperature and mixing control. Its wide temperature range and high chemical resistance make it suitable for research labs and pilot plants.Pharmaceutical Process Development

Used extensively in pharmaceutical R&D, this reactor supports crystallization, solvent recovery, and compound purification under precise thermal and stirring conditions.Polymerization Experiments

Perfect for testing different monomer reactions in polymer science. The Double Layer Reactor allows safe, scalable experimentation with controlled pressure and temperature.Petrochemical and Catalyst Studies

The reactor enables simulation of industrial conditions on a lab scale, helping in catalytic reaction testing, hydrothermal synthesis, and stability studies of new materials.Food and Flavor Engineering

Applicable in extracting or synthesizing natural compounds under mild to extreme temperatures, especially in food chemistry labs focusing on flavor or fragrance development.Environmental and Waste Treatment Research

Suitable for developing chemical treatment methods for hazardous substances, or studying the degradation and transformation of pollutants under specific lab-controlled settings.Academic Research and Education

Widely used in university and research institutions for reaction mechanism studies, thermal property analysis, and process engineering education.

peculiarity

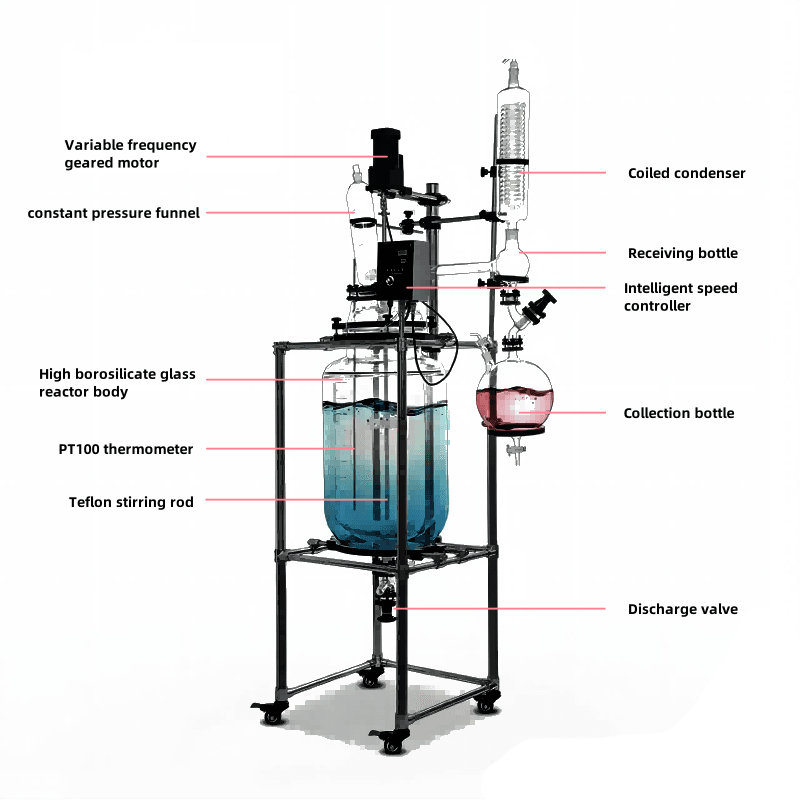

Bottom Discharge Port

High borosilicate glass, anti-corrosion and corrosion-resistant

Spiral condenser

Inner tube spiral, cooling area Large, more effective condensation

High borosilicate glass

Corrosion-resistant,High temperature resistance 300'C, high borosilicate The glass has a low expansion rate and is resistant to high

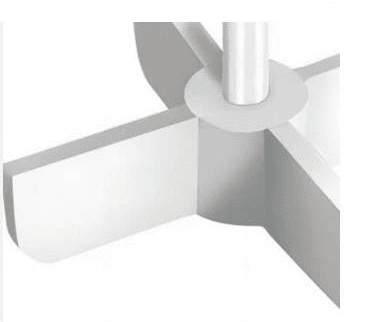

PTFE stir bar

PTFE impeller is corrosion-resistant Corrosion/acid and alkali resistance

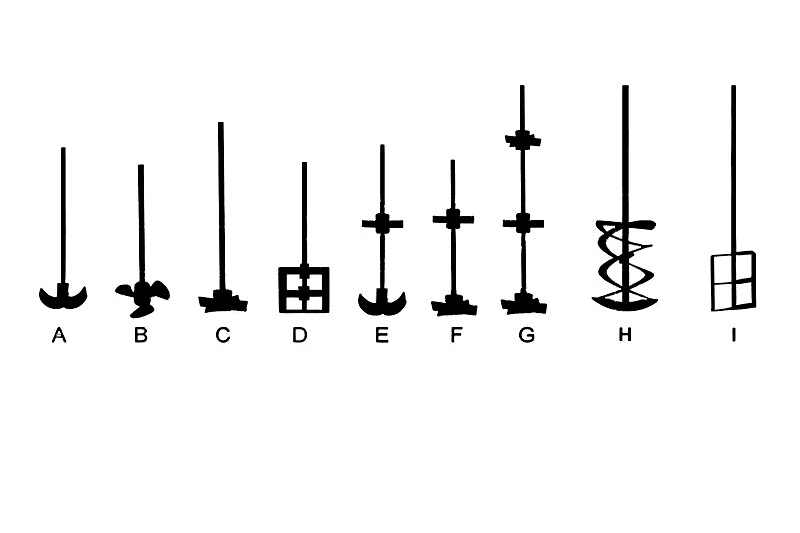

Multiple stirring paddles available for your selection

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well