Detailed Description

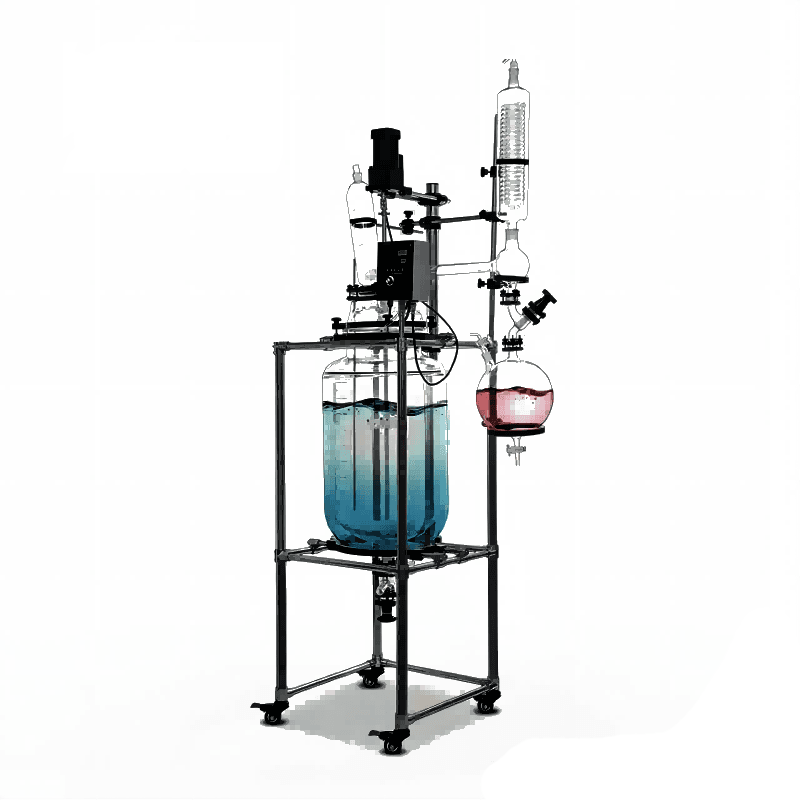

Key Features of the Laboratory Double Layer Glass Reactor

Large Capacity Reaction Vessel: With a 50L material volume and 30L mezzanine jacket, suitable for mid- to large-scale laboratory experiments.

Excellent Thermal Performance: Operates from -120°C to 300°C, suitable for exothermic and endothermic reactions.

Customizable Ports: Six standard ports allow flexible integration of sensors, feeding funnels, and condensers.

Durable Stirring System: Features a stainless steel stirring shaft covered with fluorine material for corrosion resistance and high chemical compatibility.

Stable and Adjustable Mixing: Rotational speed adjustable from 0 to 400 rpm, driven by a robust motor.

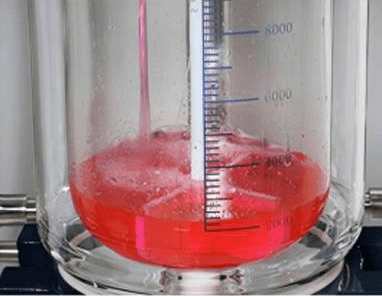

High Visibility and Safety: Double layer borosilicate glass provides clear observation and strong resistance to chemical attack.

Technical Specifications

Material Capacity: 50L

Mezzanine Capacity: 30L

Number of Ports: 6 (Customizable)

Constant Pressure Funnel: 2L

Stirring Paddle: Stainless Steel with Fluorine Coating

Coverage Diameter: 260mm

Inner Cylinder Diameter: 220mm

Outer Cylinder Diameter: 410mm

Vessel Height: 820mm

Rotational Speed: 0–400 rpm

Stirring Shaft Diameter: 17mm

Voltage / Frequency: 220V / 50Hz

Temperature Range: -120°C to 300°C

Compatible Equipment

Low Temperature Cooling Circulator – Maintains sub-zero temperatures for cryogenic reaction control.

Heating Circulator – Delivers stable heating, essential for thermal regulation in chemical reactions.

Vacuum Pump – Supports vacuum distillation and solvent recovery with the Laboratory Double Layer Glass Reactor.

Condenser and Collection Flask Set – Useful for reflux, condensation, and solvent separation setups.

Explosion-Proof Control Box – Enhances safety in high-risk laboratory environments.

Outstanding Benefits of the Laboratory Double Layer Glass Reactor

The Laboratory Double Layer Glass Reactor 50L delivers a balanced combination of high-capacity reaction volume, exceptional chemical resistance, and stable thermal control. Designed to handle a wide temperature range and equipped with a corrosion-resistant stirring system, it provides unparalleled performance for chemical synthesis, pharmaceutical development, and pilot-scale research. It is the ideal solution for labs requiring versatility, safety, and operational precision.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Discover More Laboratory Double Layer Glass Reactor Models

Explore more models in our Laboratory Double Layer Glass Reactor series for advanced chemical reaction solutions.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKF-10L | AKF-20L | AKF-30L | AKF-50L | AKF-100L | AKF-150L | AKF-200L |

|---|---|---|---|---|---|---|---|

| Material Capacity (L) | 10L | 20L | 30L | 50L | 100L | 150L | 200L |

| Mezzanine Capacity (L) | 6 | 10 | 16 | 30 | 60 | ||

| Number of Ports | 6 (Customizable) | ||||||

| Constant Pressure Funnel | 1L | 2L | 5L | ||||

| Stirring Paddle | Stainless Steel Covered with Fluorine Material | ||||||

| Coverage Diameter (mm) | 260 | 340 | |||||

| Inner Cylinder Diameter (mm) | 220 | 290 | 340 | ||||

| Outer Cylinder Diameter (mm) | 270 | 370 | 410 | 500 | 600 | 690 | |

| Vessel Height (mm) | 500 | 635 | 710 | 820 | 1070 | 1170 | 1280 |

| Rotational Speed (rpm) | 0-450 | 0-450 | 0-450 | 0-400 | 0-350 | 0-300 | 0-250 |

| Stirring Shaft Diameter (mm) | 15 | 15 | 15 | 17 | 20 | 22 | 25 |

| Voltage Frequency | 220V/50Hz | ||||||

| Temperature Range | Low -120°C to High 300°C | ||||||

introduce

Product features:

Chemical Synthesis in Research Laboratories

The laboratory double layer glass reactor 50L is ideal for controlled chemical synthesis in academic and industrial R&D labs. Its large material capacity and wide temperature range from -120°C to 300°C allow researchers to perform reactions under precisely regulated thermal conditions.Pharmaceutical Process Development

This double layer glass reactor is widely used in pharmaceutical labs for drug formulation testing and compound synthesis. Its chemical-resistant glass construction ensures purity, while the double-layer design provides stable thermal control essential for sensitive reactions.Pilot-Scale Experiments in Biochemical Engineering

Thanks to its 50L reaction volume and 30L jacketed layer, this reactor supports scale-up from bench-top to pilot-scale. It’s suitable for enzyme reactions, fermentation processes, and metabolic pathway testing under reproducible thermal and stirring conditions.Material Science Research and Polymerization

In materials research, the double layer glass reactor enables polymer synthesis, nanoparticle development, and sol-gel processing. The precise stirring system and stable jacketed temperature control are critical for producing consistent material properties.Petrochemical Testing and Analysis

Petrochemical engineers use this laboratory double layer glass reactor for evaluating catalyst performance, performing hydrothermal reactions, and testing additives under high or low temperatures, all with safe glass containment.Environmental and Agricultural Chemistry Applications

The reactor’s versatility supports research in environmental remediation (e.g., degradation studies of pollutants) and agricultural compound development, such as synthesizing fertilizers or plant-growth regulators with temperature-sensitive processes.Educational Demonstrations in Universities

For teaching purposes in chemical engineering and applied science departments, the 50L double layer glass reactor offers a visible and safe way to demonstrate reaction mechanisms, thermal control principles, and scale-up strategies.

peculiarity

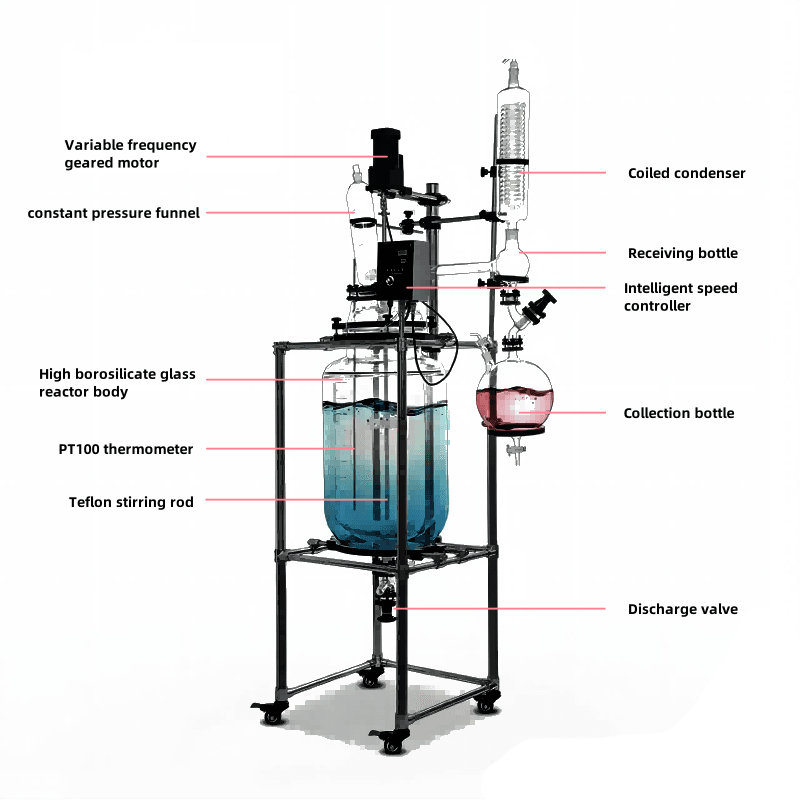

Bottom Discharge Port

High borosilicate glass, anti-corrosion and corrosion-resistant

Spiral condenser

Inner tube spiral, cooling area Large, more effective condensation

High borosilicate glass

Corrosion-resistant,High temperature resistance 300'C, high borosilicate The glass has a low expansion rate and is resistant to high

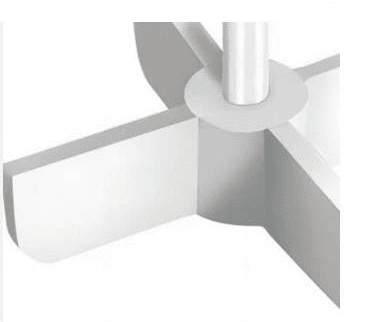

PTFE stir bar

PTFE impeller is corrosion-resistant Corrosion/acid and alkali resistance

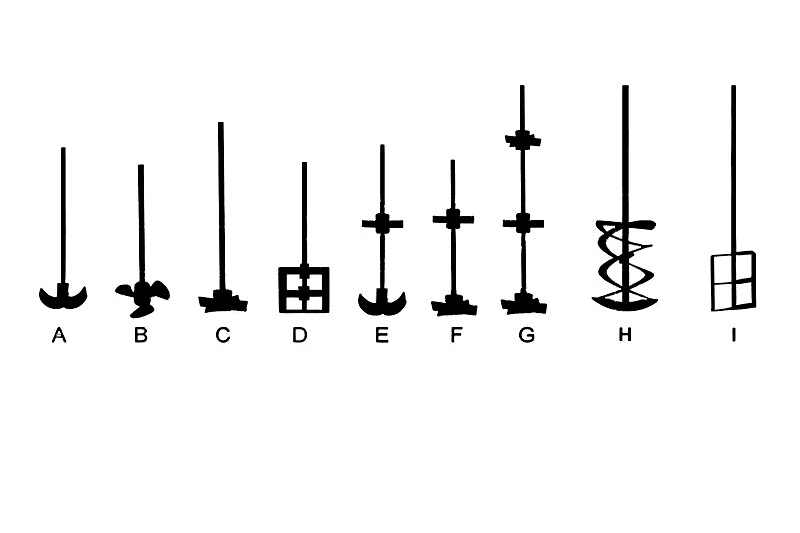

Multiple stirring paddles available for your selection

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well