Detailed Description

Main Features

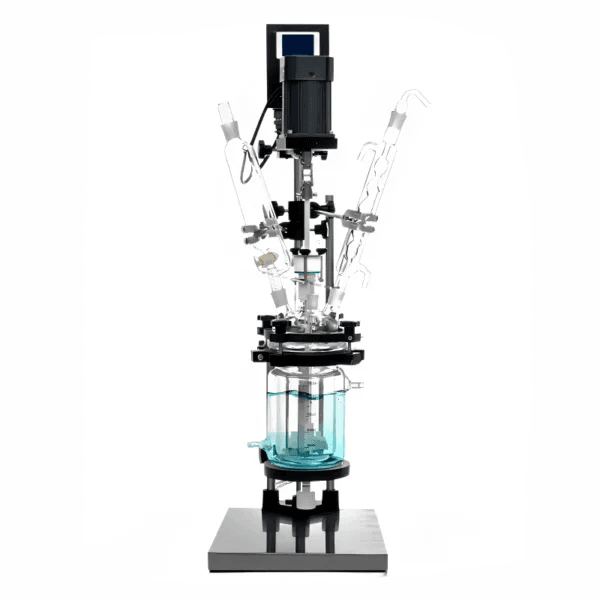

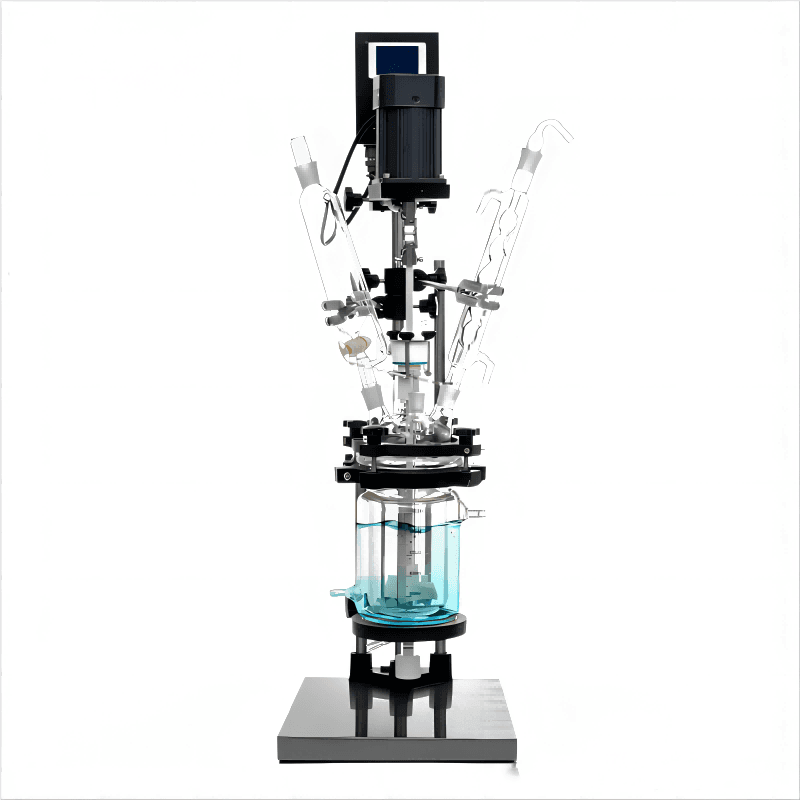

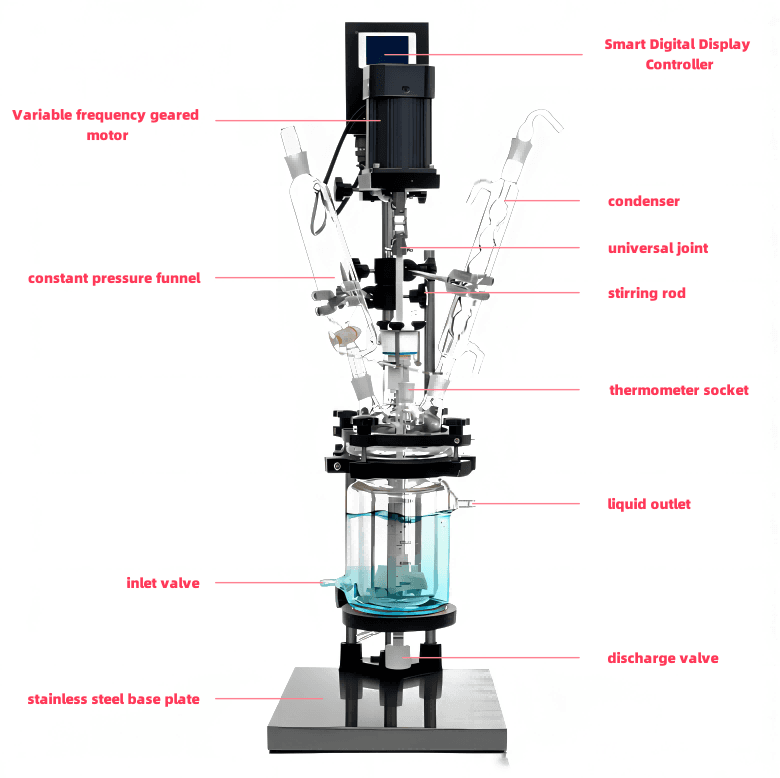

Double Jacketed Glass Reactor with 5L material capacity and 2L mezzanine layer

Supports temperatures from -120°C to +300°C for a wide range of experiments

Five customizable ports for sensors, condensers, or dosing systems

PT100 sensor probe for high-precision temperature monitoring

Fluorine-coated stainless steel stirring paddle ensures chemical resistance

Gimbal connection design enables stable and adjustable stirring

Optional explosion-proof motor, insulated clothing, and control box for safety

Transparent structure for easy visual monitoring during reactions

Technical Specifications

Material Capacity: 5 L

Mezzanine Capacity: 2 L

Number of Ports: 5 (Customizable)

Constant Pressure Funnel: 500 ml

Stirring Paddle: Stainless Steel Covered with Fluorine Material

Coverage Diameter: 200 mm

Inner Cylinder Diameter: 170 mm

Outer Cylinder Diameter: 230 mm

Vessel Height: 430 mm

Rotational Speed: 0–1350 rpm

Stirring Shaft Diameter: 8 mm

Stirring Connection: Gimbal Connection

Voltage / Frequency: 220V / 50Hz

Temperature Range: -120°C to +300°C

Temperature Probes: PT100 Sensor Probe

Explosion-proof Control Box: Optional

Insulated Clothing: Optional

Explosion-proof Motor: Optional

Recommended Compatible Equipment

Low-Temperature Circulator – For maintaining stable operation of the Double Jacketed Glass Reactor under sub-zero conditions

Rotary Evaporator – Useful for post-reaction solvent removal and concentration

Vacuum Pump – For distillation, filtration, or vacuum reactions inside the reactor

Refrigerated Chiller – Supports consistent jacket cooling and thermal control

Overhead Stirrer – Assists with high-viscosity solutions in the Double Jacketed Glass Reactor

Emphasizing the Benefits

The Double Jacketed Glass Reactor 5L delivers exceptional control and adaptability for lab-scale research. Its dual-layer design enhances thermal efficiency while supporting vacuum and pressure reactions. This Double Jacketed Glass Reactor accommodates varied experiment setups with flexible ports and a reliable stirring system, making it a go-to solution for laboratories seeking performance and reliability.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Options

Discover more configurations in our double jacketed glass reactor category for tailored laboratory applications.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKF-1L | AKF-2L | AKF-3L | AKF-5L |

|---|---|---|---|---|

| Material Capacity (L) | 1L | 2L | 3L | 5L |

| Mezzanine Capacity (L) | 1 | 1.5 | 2 | 2 |

| Number of Ports | 5 (Customizable) | |||

| Constant Pressure Funnel | 250ML | 500ML | ||

| Stirring Paddle | Stainless Steel Covered with Fluorine Material | |||

| Coverage Diameter (mm) | 150 | 190 | 200 | |

| Inner Cylinder Diameter (mm) | 100 | 150 | 170 | |

| Outer Cylinder Diameter (mm) | 150 | 170 | 200 | 230 |

| Vessel Height (mm) | 320 | 370 | 395 | 430 |

| Rotational Speed (rpm) | 0-1350 | |||

| Stirring Shaft Diameter (mm) | 8 | |||

| Stirring Connection | Gimbal Connection | |||

| Voltage Frequency | 220V/50Hz | |||

| Temperature Range | Low -120°C to High 300°C | |||

| Temperature Probes | PT100 Sensor Probe | |||

| Explosion-proof Control Box | Optional | |||

| Insulated Clothing | Optional | |||

| Explosion-proof Motor | Optional | |||

introduce

Application Scenarios

Chemical synthesis and reactions requiring precise temperature control between -120°C and +300°C

Pharmaceutical research and development for formulation and compound testing

Polymerization processes where controlled heating and cooling are essential

Vacuum distillation and reflux reactions using customizable ports for condensers and sensors

Fine chemical production involving corrosive or sensitive materials, utilizing fluorine-coated stirring paddle

Laboratory scale scale-up experiments to simulate industrial conditions

Biochemical processes needing sterile and transparent reactor environment

Material science research for thermal property analysis and reaction kinetics

Catalyst testing and reaction optimization under controlled stirring and temperature conditions

Teaching laboratories for practical demonstrations of chemical reaction principles

peculiarity

thickened glass reactor body

Inject Constant Temperature Circulating Liquid into the Central Layer Regulates the Temperature Inside the Reactor Open Design

Stirring System

Custom Variable Frequency Motor, LCD Display Stable, Can Operate Continuously Low Noise Speed Controller, Safe

Discharge valve

Discharge valve with a glass and PTFE combination Corrosion-resistant and non-contaminating No residue accumulation, flow rate adjustable

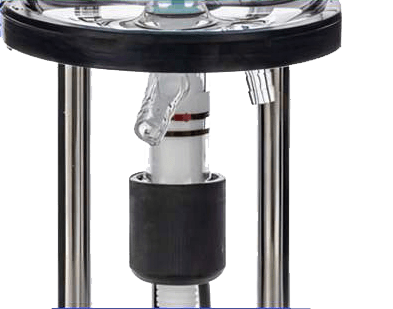

Corrosion-resistant sealing system

-0.098MPA:Uses PTFE and mechanical double-layer sealing, vacuum achievable to -0.098 MPa Non-contaminating

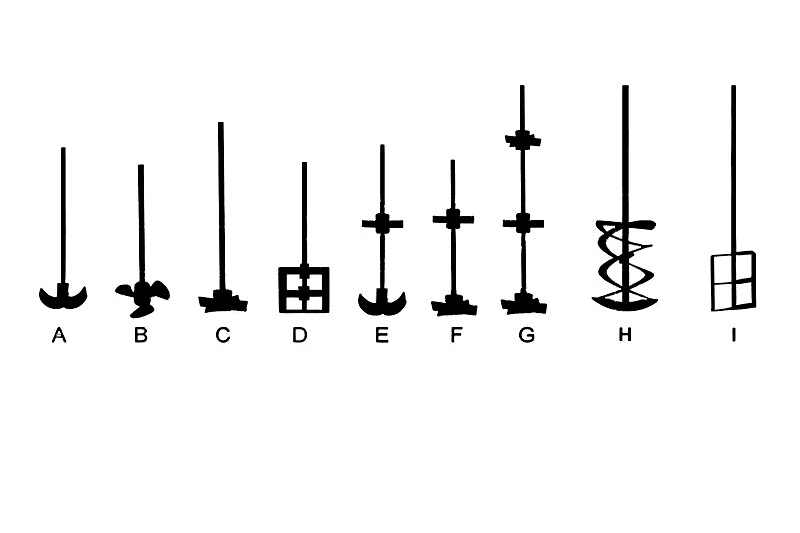

Multiple stirring paddles available for your selection

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well