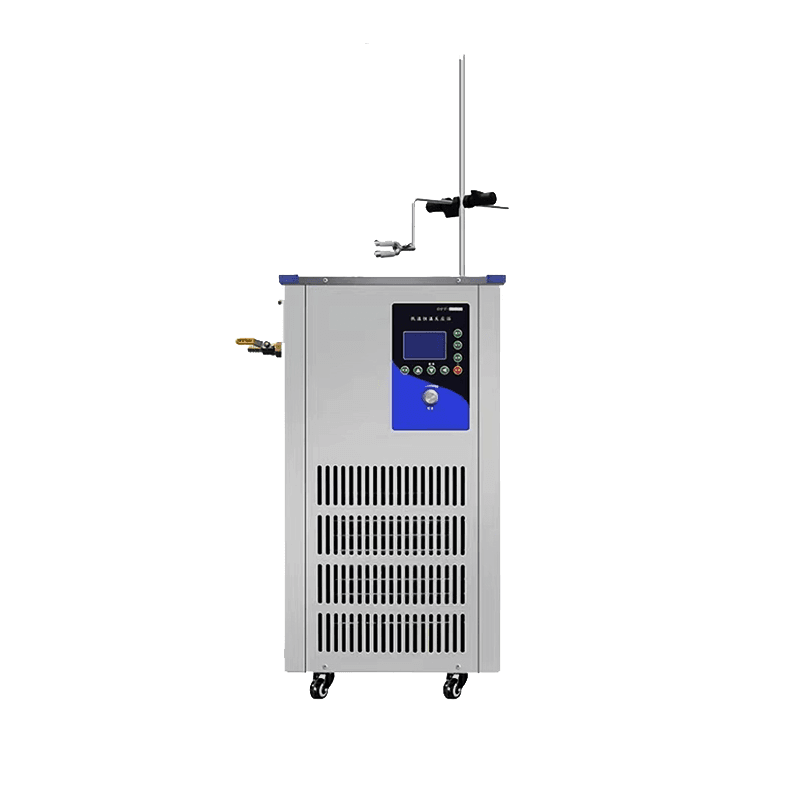

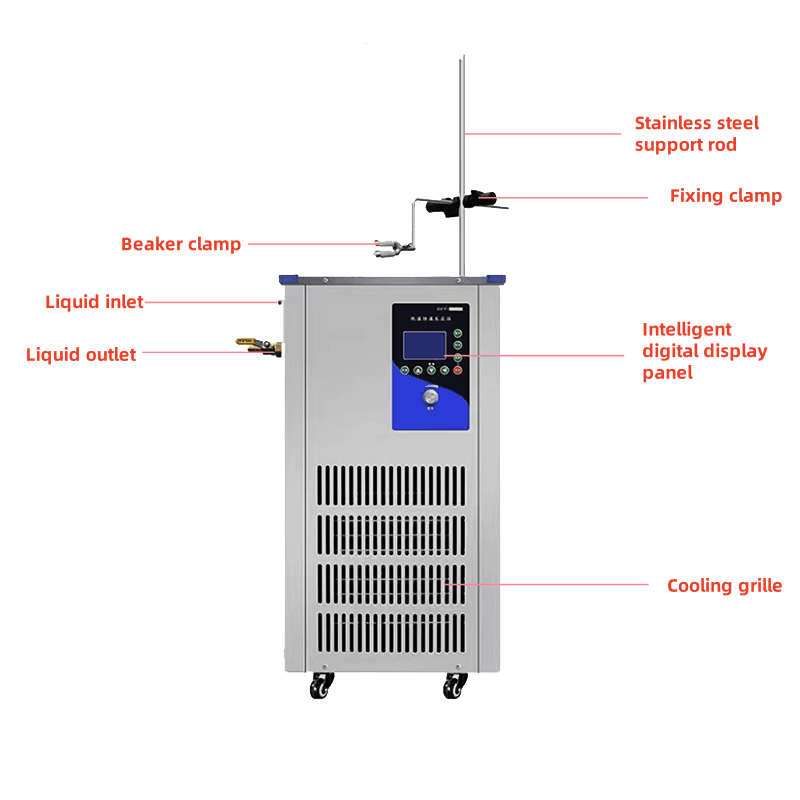

Detailed Description

Key Features

Wide Temperature Range: Models offer -20℃ to -120℃ minimums, all with a +99℃ upper limit, enabling both low-temp and heating applications.

20L Storage Capacity: Ideal for medium-scale lab operations requiring precise thermal processing.

Magnetic Bottom Stirring: Ensures uniform temperature distribution throughout the fluid.

Temperature Accuracy ±0.5℃: Maintains stable reaction conditions for sensitive processes.

Powerful Heating System: 3000W heater rapidly reaches setpoint temperatures.

Efficient Circulating Pump: 100W motor ensures continuous, uniform flow within the tank.

Safety Protections: Includes delay start, overload prevention, and overheat shutdown.

Durable Construction: Cold-rolled steel body with anti-corrosion plastic coating and nickel-plated copper cooling coil.

Display & Control: LCD digital screen with responsive button operation for clear temperature monitoring.

Optional Features: Explosion-proof compressor and controller available for high-risk environments.

Technical Specifications

Model Variants and Compressor Power:

AKFY-20/20: -20 to +99℃, 1103W

AKFY-20/30: -30 to +99℃, 1200W

AKFY-20/40: -40 to +99℃, 2205W

AKFY-20/60: -60 to +99℃, 2500W

AKFY-20/80: -80 to +99℃, 4410W

AKFY-20/120: -120 to +99℃, 6615W

Common Specifications:

Storage Capacity: 20L

Temperature Control Accuracy: ±0.5℃

Open Diameter: 285mm

Discharge Volume: 5L

Stirring Method: Magnetic stirring at tank bottom

Heating Power: 3000W

Circulating Pump Power: 100W

Cooling Coil: Nickel-plated copper

Condenser Type: Air-cooled (optional water-cooled)

Display & Control: LCD digital, button-operated

Body Material: Cold-rolled steel with corrosion-resistant coating

Ambient Temperature: 5–35℃

Humidity Range: 60%–80%, ventilated

Power Supply: 380V / 50Hz

Explosion-Proof Options: Compressor and controller (optional)

Compatible Equipment Recommendations

Vacuum Filtration Units – Ideal for combining with the bath for temperature-controlled separation processes.

Low-Temperature Circulating Chillers – Useful when additional external cooling is needed or when upgrading to a water-cooled condenser.

Reflux Condensers – For closed-loop experiments where condensation and temperature regulation must be maintained.

Thermal Sensors and Controllers – To integrate with automated lab control systems for remote monitoring and precision regulation.

Glass Reactors – Perfect for chemical synthesis when connected to a temperature control source like this bath.

Performance and Reliability You Can Trust

This Cooling Heating and Stirring Reaction Bath delivers reliable, high-precision thermal control and fluid agitation in a compact, durable system. Whether you are developing pharmaceuticals, studying reaction kinetics, or maintaining biological samples at exact temperatures, this unit provides the control, efficiency, and flexibility required in professional lab environments. The optional explosion-proof components further ensure operational safety in volatile experimental conditions.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Low-Temperature Reaction Baths

Browse our full range of cooling and heating bath systems here: Low-Temperature Reaction Bath Product Category

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKFY-20/20 | AKFY-20/30 | AKFY-20/40 | AKFY-20/60 | AKFY-20/80 | AKFY-20/120 |

|---|---|---|---|---|---|---|

| Temperature Range (℃) | -20~+99 | -30~+99 | -40~+99 | -60~+99 | -80~+99 | -120~+99 |

| Storage Capacity (L) | 20 | |||||

| Best Ambient Temperature (℃) | 5~35 | |||||

| Ambient Humidity | ≥60-80% ventilation | |||||

| Temperature Control Accuracy (℃) | ±0.5 | |||||

| Practical Open Diameter (mm) | 285 | |||||

| Discharge Volume (L) | 5 | |||||

| Stirring | Magnetic stirring at the bottom of the liquid storage tank | |||||

| Safety Protection | Delay/Overload/Overheat | |||||

| Display Method | LCD digital display, button operation | |||||

| Cooling Coil | Nickel-plated copper tube | |||||

| Body Material | Cold-rolled sheet sprayed with anti-corrosion plastic | |||||

| Heating Power (W) | 3000 | |||||

| Compressor Power (W) | 1103 | 1200 | 2205 | 2500 | 4410 | 6615 |

| Circulating Pump Power (W) | 100 | |||||

| Condenser | Air-cooled condenser (optional water-cooled) | |||||

| Power Supply | 380V/50Hz | |||||

| Explosion-proof Compressor | Optional | |||||

| Explosion-proof Controller | Optional | |||||

introduce

Application Scenarios

Pharmaceutical Research and Development

Used for precise temperature-controlled synthesis and crystallization of active pharmaceutical ingredients (APIs), ensuring uniform mixing and thermal stability during reactions.Chemical Synthesis and Analysis

Ideal for conducting exothermic or endothermic reactions that require accurate temperature profiles and consistent magnetic stirring to ensure uniform reaction conditions.Biochemical and Enzyme Reactions

Supports low-temperature enzymatic reactions where exact temperature control and gentle stirring are critical to preserving enzyme activity and reaction efficiency.Material Science and Nanomaterials

Enables temperature-sensitive processing such as polymerization, sol-gel synthesis, or nanomaterial dispersion where consistent thermal and stirring conditions are crucial.Food and Beverage Quality Testing

Applied in controlled heating or cooling of samples for stability tests, extraction procedures, or viscosity studies, ensuring reproducibility of test conditions.Environmental Sample Processing

Suitable for the preparation and conditioning of environmental samples requiring thermal treatment or mixing before analysis (e.g., soil or water testing protocols).Petrochemical Laboratory Workflows

Used in oil analysis, additive formulation, and fuel component testing, especially when samples must be maintained at specific temperatures for extended periods.Education and Academic Laboratories

Essential for university chemistry and biology labs conducting various heating, cooling, and reaction experiments with precise parameters for student learning and research.

peculiarity

Variable Frequency Compressor

Uses a leading brand fully enclosed compressor, occupying minimal space, with high heat exchange efficiency, providing effective cooling with safety and stability.

Solution 1

Combines a rotary evaporator with a circulating water vacuum pump to form a complete and integrated system.

Louvered Cooling Window

Features a louvered design for efficient heat dissipation, allowing for rapid cooling and ensuring stable machine operation.

Solution 2

Combines a double-layer glass reactor with its own circulation system to transfer the cooling medium to the reactor for circulation. This setup enables the glass reactor to conduct low-temperature reaction experiments on materials.