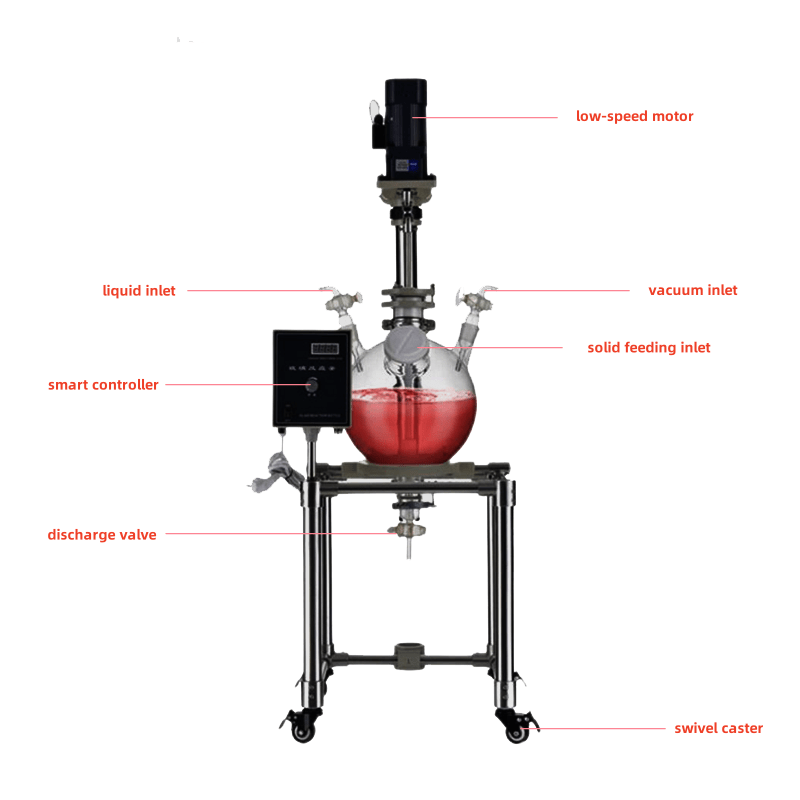

Detailed Description

Key Features

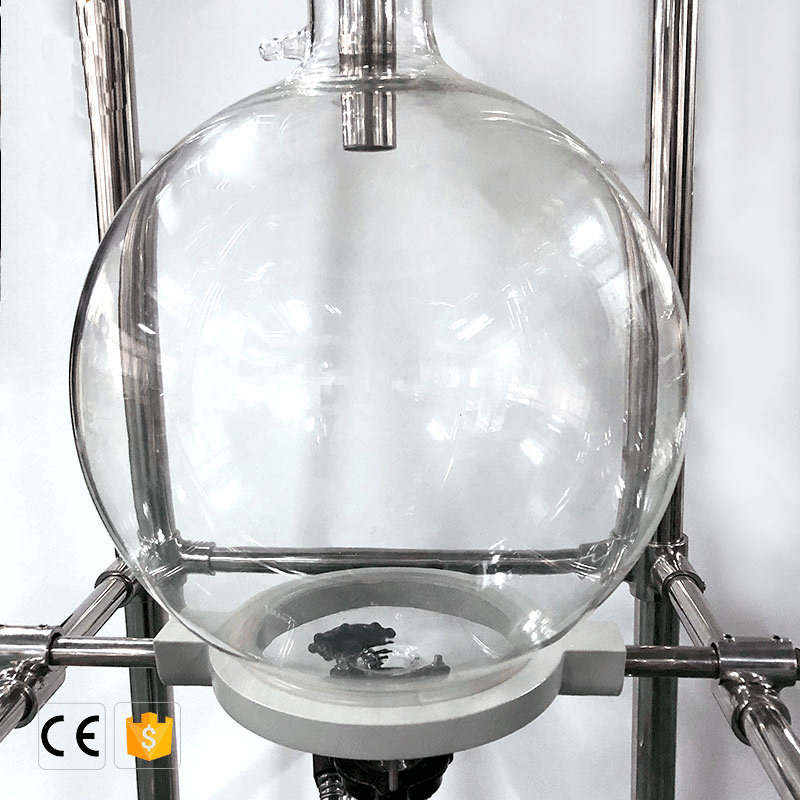

50L borosilicate glass body supports visual monitoring and chemical resistance

Maximum 80% loading capacity ensures effective phase separation

120W motor drives smooth stirring at 0–450 rpm

Stainless steel stirring rod coated with PTFE for chemical durability and inertness

High vacuum capability up to 0.098 Mpa improves separation precision

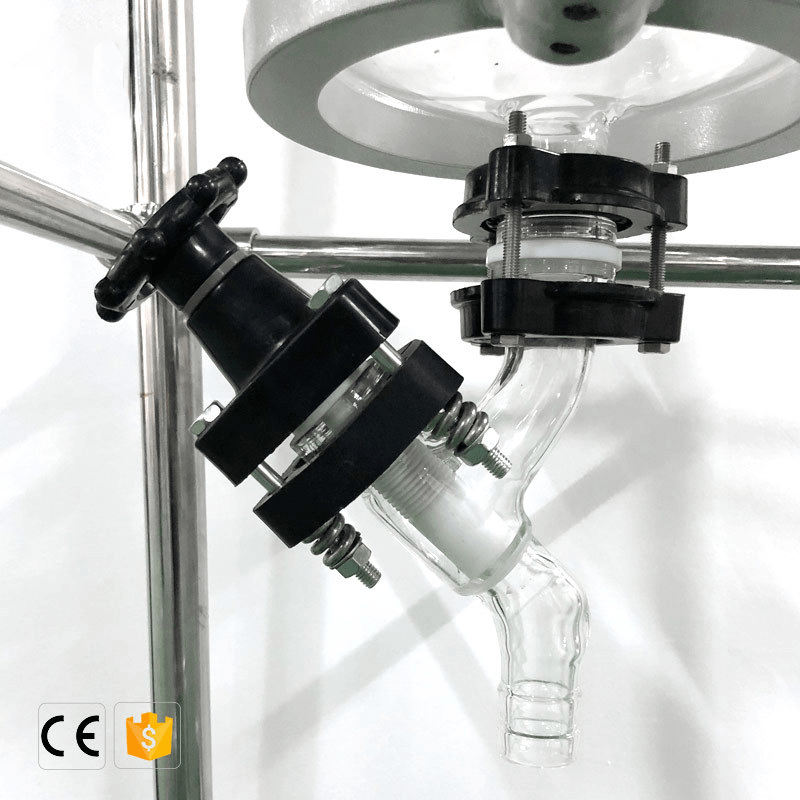

PTFE discharge valve ensures residue-free drainage with no dead angles

304 stainless steel frame (Teflon-coated option available) for enhanced durability

Operates safely at 220V/50Hz, suitable for most lab setups

Technical Specifications

Model: 50L Glass Separator Extractor For Liquid

Glass Volume: 50L

Loading Capacity: ≤80%

Motor Power: 120W

Rotation Speed: 0–450 rpm

Stirring Rod Diameter: 17mm

Stirring Rod Material: Stainless Steel coated with PTFE

Vacuum Degree: 0.098 Mpa

Frame Material: 304 Stainless Steel (optional Teflon coating)

Discharge Valve: PTFE core, corrosion-resistant, residue-free

Voltage: 220V/50Hz

Compatible Equipment

Rotary Evaporator – Ideal for solvent recovery and concentration after separation

Vacuum Pump – Provides stable vacuum conditions to enhance liquid-liquid separation efficiency

Reactor Vessels – Complements chemical synthesis setups requiring post-reaction phase separation

Freeze Dryer – Enables drying of aqueous or organic separated fractions after extraction

Liquid Collection Tanks – Useful for collecting separated organic or aqueous layers during continuous operations

Why Choose This Glass Separator Extractor?

This 50L Glass Separator Extractor For Liquid is engineered to deliver precision, stability, and chemical durability in every use. Whether in a high-throughput extraction lab or a university research setting, its vacuum-assisted design, variable stirring, and PTFE components ensure that separation is efficient, residue-free, and repeatable. The corrosion-resistant materials make it a long-term solution even for aggressive solvents or acidic systems.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore Related Products

Discover more Glass Separator Extractor For Liquid models in our liquid-liquid separator category for tailored solutions to your laboratory needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKFY-10L | AKFY-20L | AKFY-30L | AKFY-50L | AKFY-100L |

|---|---|---|---|---|---|

| Glass Volume (L) | 10L | 20L | 30L | 50L | 100L |

| Loading Capacity | ≦80% | ||||

| Motor Power | 120W | ||||

| Rotation Speed | 0-450rpm | ||||

| Stirring Rod Diameter | 10mm | 12mm | 17mm | ||

| Stirring Rod Material | Stainless Steel Coated with PTFE (Various options available) | ||||

| Vacuum Degree | 0.098Mpa | ||||

| Frame Material | 304 Stainless Steel (Optional Spray Teflon) | ||||

| Discharge Valve | PTFE Valve Core, Corrosion-resistant, No Dead Angle Stirring, No Liquid Residue | ||||

| Voltage | 220V/50Hz | ||||

introduce

Application Scenarios

Chemical Liquid-Liquid Extraction

Ideal for separating immiscible liquids in chemical synthesis, purification, and post-reaction separation.Pharmaceutical Process Separation

Used in pharmaceutical labs to isolate organic and aqueous phases during compound formulation or active ingredient extraction.Biotechnology Sample Preparation

Suitable for extracting compounds from biological mixtures, aiding in downstream processing of bio-products.Food and Beverage Testing Labs

Useful for separating oil-water mixtures or solvents in quality control and food-grade material analysis.Environmental Analysis

Applied in laboratories to separate and analyze pollutant layers in water or soil samples.Research and Development

Perfect for R&D departments needing precise and repeatable liquid-liquid extraction for formulation or experimental scale-up.

peculiarity

High-Performance PTFE Stirring Rod

Corrosion-resistant and durable against acids and bases, ideal for laboratory use.

Swivel Caster Wheels with Locking Function

Swivel caster wheels enable smooth movement and feature a reliable locking mechanism for secure positioning. Durable and versatile, they are perfect for various applications, combining convenience with stability.

Bottom Discharge Valve

No Dead Angle Discharge, Corrosion-Resistant, Pollution-Free, and Long-Lasting.

Thickened High Borosilicate Glass

Durable and Sturdy, Easy to Clean, Shatter-Resistant, with Excellent Transparency for Easy Observation.