Detailed Description

Key Features

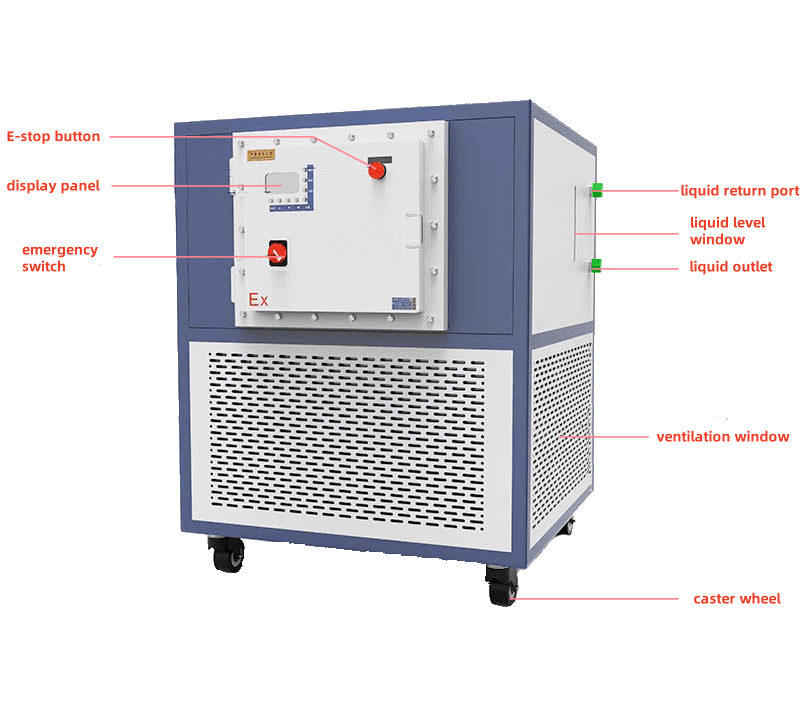

Explosion Proof Closed Heating Circulator with wide -30°C to 200°C operating range

Temperature stability of ±1°C for consistent thermal performance

Fully enclosed rotary compressor (2 HP) using R22 refrigerant

Heating power of 5 kW and cooling power of 1.47 kW

Air-cooled design eliminates the need for external water supply

Built-in 370W circulating pump with 42 L/min flow and 22 bar pressure

SUS304 stainless steel tank, valves, and pipelines for corrosion resistance

15L internal liquid capacity with closed-loop design for safety and efficiency

Technical Specifications

Model: AKGD-20L/-30+200

Temperature Range: -30°C to 200°C

Temperature Stability: ±1°C

Ambient Temperature: 5°C–35°C

Best Ambient Humidity: ≤60%

Power Supply: 1PH / 220V / 50Hz

Total Power: 6.84 kW / 31.1 A

Heating Power: 5 kW

Cooling Power: 1.47 kW

Cooling Method: Air-cooled

Compressor Model: QX-D29F050

Compressor Power: 2 HP

Refrigerant: R22

Cooling Capacity:

– @200°C: 6.42 kW

– @30°C: 4.5 kW

– @10°C: 4.38 kW

– @-5°C: 3.16 kW

– @-10°C: 2.23 kW

– @-20°C: 1.31 kW

– @-30°C: 0.65 kW

Circulating Pump Power: 370 W

Flow Rate: 42 L/min

Pump Pressure: 22 bar

External Interface Size: DN15

Internal Liquid Capacity: 15 L

Circulating Medium: Silicone oil (below 50cs)

Tank and Piping Material: SUS304

Compatible Equipment

Glass Reactor Systems – Use with the Explosion Proof Closed Heating Circulator for precise control during chemical reactions.

High-Pressure Reactors – Ideal for maintaining stable thermal conditions in high-pressure, volatile environments.

Rotary Evaporators – Ensures efficient solvent recovery through rapid heating and cooling cycles.

Distillation Columns – Enables accurate temperature transitions during separation processes.

Vacuum Freeze Dryers – Pre-cools materials to required low temperatures before drying.

Why Choose This Explosion Proof Closed Heating Circulator

This Explosion Proof Closed Heating Circulator offers unmatched reliability, safety, and efficiency in temperature-sensitive applications. Its explosion-proof design is ideal for handling flammable chemicals, and the closed-loop system ensures zero leakage and consistent performance. Constructed from high-grade stainless steel and equipped with powerful heating and cooling capabilities, the unit is suitable for both research and production-scale operations.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Circulators

Explore more models in our Explosion Proof Closed Heating Circulator category for a complete range of thermal control solutions.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | Specifications |

|---|---|

| Model | AKGD-20L/-30+200 |

| Temperature Stability (℃) | ±1 |

| Operating Temperature Range (℃) | -30~200 |

| Ambient Temperature (℃) | 5~35 |

| Best Ambient Humidity | ≤60% |

| Power Supply | 1PH/220V/50HZ |

| Total Power (kW/A) | 6.84/31.1 |

| Cooling Power (kW) | 1.47 |

| Heating Power (kW) | 5 |

| Cooling Method | Air-cooled |

| Compressor Model | QX-D29F050 |

| Compressor Power (HP) | 2 |

| Refrigerant | R22 |

| Type | Fully Enclosed Rotary Compressor |

| Cooling Capacity (kW) @ 200℃ | 6.42KW |

| Cooling Capacity (kW) @ 30℃ | 4.5KW |

| Cooling Capacity (kW) @ 10℃ | 4.38KW |

| Cooling Capacity (kW) @ -5℃ | 3.16KW |

| Cooling Capacity (kW) @ -10℃ | 2.23KW |

| Cooling Capacity (kW) @ -20℃ | 1.31KW |

| Cooling Capacity (kW) @ -30℃ | 0.65KW |

| Circulating Pump Power (W) | 370W |

| Circulating Pump Flow Rate (L/min) | 42 |

| Circulating Pump Pressure (bar) | 22 |

| External Circulation Interface Size | DN15 |

| Heat Transfer Fluid Tank Material | SUS304 |

| Heat transfer fluid piping and valve materials | SUS304 |

| Circulating Medium | Silicone oil below 50cs |

| Internal Liquid Capacity (L) | 15 |

introduce

Application Scenarios

Ideal for chemical synthesis processes involving flammable and explosive substances, ensuring safe operation and precise temperature control to prevent hazards.

Widely used in pharmaceutical laboratories, meeting high demands for temperature stability and safety during drug development and production.

Suitable for petrochemical labs, safely handling organic solvents and volatile materials to protect equipment and personnel.

Supports pilot-scale production with a wide operating temperature range from -30°C to 200°C and ±1°C temperature stability, ensuring controllable and repeatable process conditions.

Perfect for quality testing and scientific research, minimizing temperature fluctuations to obtain reliable experimental data and process parameters.

Used in electronic component aging tests, providing precise temperature cycling to simulate real working environments and assess heat resistance.

Applicable in environmental simulation chambers, enabling accurate temperature variation control to mimic extreme climate conditions for product testing.

Ensures safe operation in industrial processes requiring explosion-proof thermal control, reducing risks caused by temperature anomalies.

Compatible with silicone oil and other heat transfer media circulation, improving heat exchange efficiency and maintaining long-term stable temperature control.

peculiarity

Eco Cooling: Copeland & Taikang

The refrigeration system uses an American Copeland compressor and a French Taikang high-temperature resistant circulation pump, offering stable performance. It adopts eco-friendly, CFC-free refrigerants, compliant with both EU and national standards.

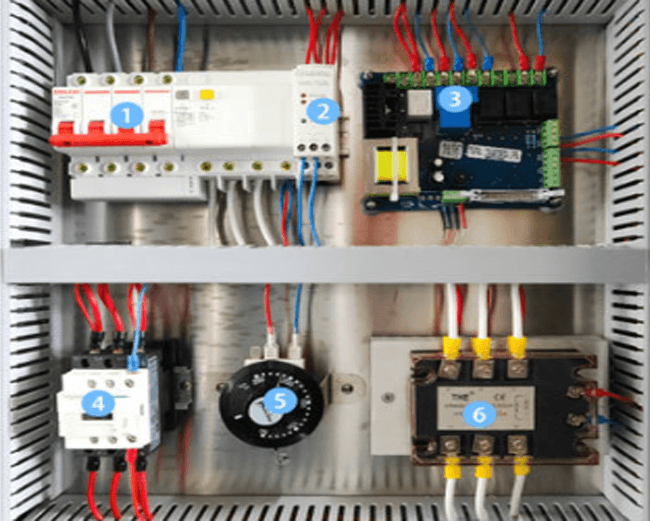

Safety-Certified Electrical Components

This equipment uses well-known brand electrical components that meet safety standards and can be equipped with explosion-proof distribution boxes.

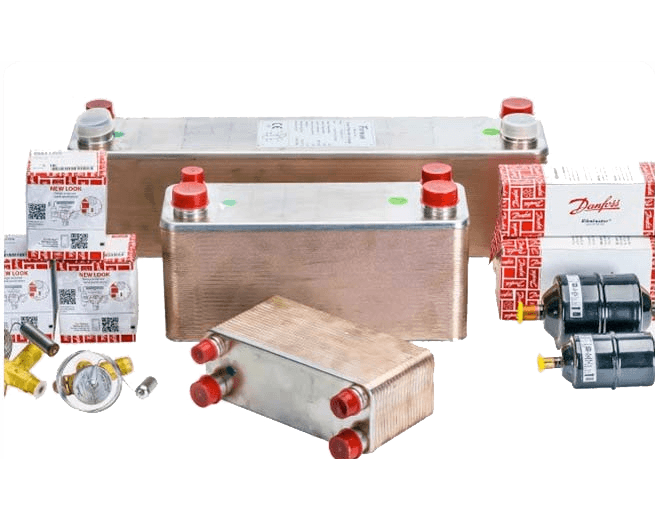

Compact, High-Efficiency Brazed Plate Heat Exchanger

The refrigeration uses a fully brazed plate heat exchanger, which is space-efficient and has high heat transfer efficiency, requiring less thermal oil.

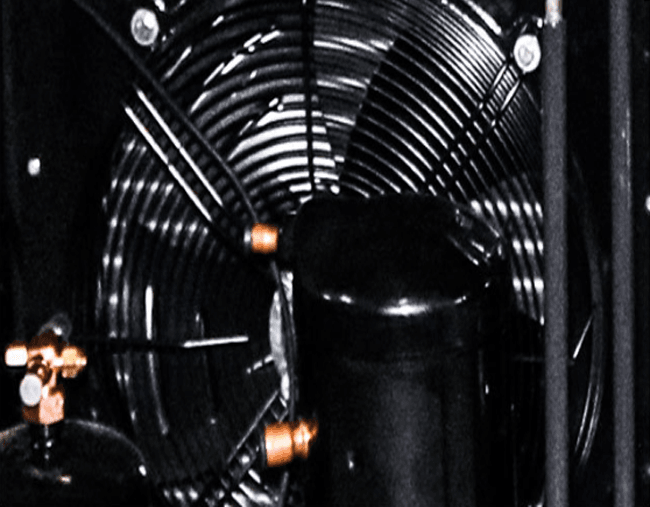

High-Efficiency Air-Cooled Condenser

Designed for superior heat dissipation and rapid cooling, our air-cooled condenser ensures optimal performance and fast temperature reduction