Product specifications

| Parameter | Specifications |

|---|---|

| Model | AKGD-50L/-30+200 |

| Temperature Stability (℃) | ±1 |

| Operating Temperature Range (℃) | -30~200 |

| Ambient Temperature (℃) | 5~35 |

| Best Ambient Humidity | ≤60% |

| Power Supply | 3PH/380V/50HZ |

| Total Power (kW/A) | 11.6/19.66 |

| Cooling Power (kW) | 2.25 x2 |

| Heating Power (kW) | 7.5 |

| Cooling Method | Air-cooled |

| Compressor Model | YM86A1G-100 |

| Compressor Power (HP) | 5 |

| Refrigerant | R22 |

| Type | Fully Enclosed Rotary Compressor |

| Cooling Capacity (kW) @ 100℃ | 17.4KW |

| Cooling Capacity (kW) @ 30℃ | 15.66KW |

| Cooling Capacity (kW) @ -5℃ | 11.87KW |

| Cooling Capacity (kW) @ -10℃ | 9.99KW |

| Cooling Capacity (kW) @ -20℃ | 6.89KW |

| Cooling Capacity (kW) @ -30℃ | 4.55KW |

| Circulating Pump Power (W) | 370W |

| Circulating Pump Flow Rate (L/min) | 42 |

| Circulating Pump Pressure (bar) | 22 |

| External Circulation Interface Size | DN15 |

| Heat Transfer Fluid Tank Material | SUS304 |

| Heat transfer fluid piping and valve materials | SUS304 |

| Circulating Medium | Silicone oil below 50cs |

| Internal Liquid Capacity (L) | 20 |

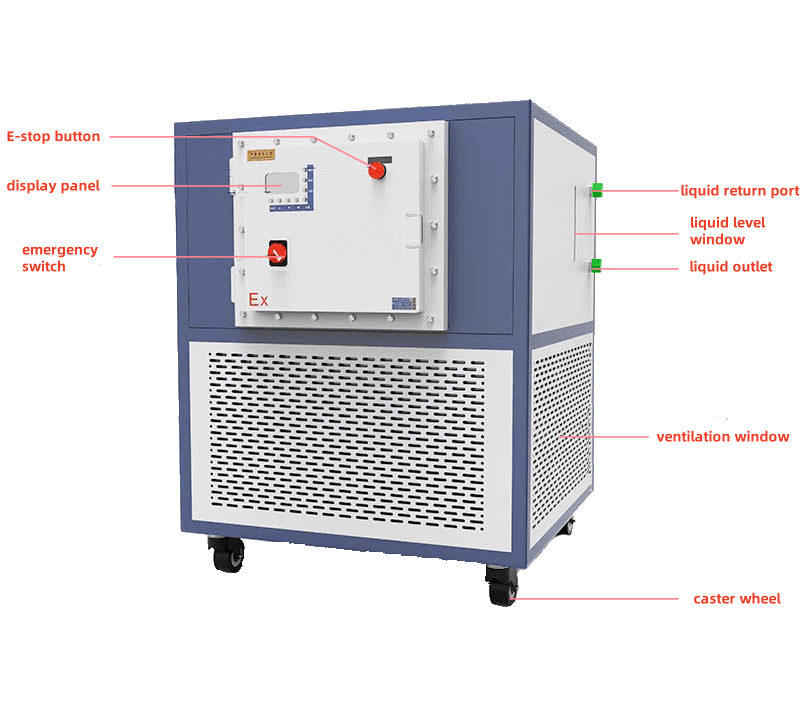

introduce

Product features:

High and Low Temperature Integrated Circulator: The Perfect Combination of Efficient Heating and Cooling

The high and low temperature integrated circulator is designed with advanced heating and cooling integration, featuring a large heat exchange surface that significantly accelerates both heating and cooling rates while reducing the consumption of thermal oil, greatly improving operational efficiency. The system supports continuous temperature rise and fall, utilizing high-temperature, high-pressure compressor technology that can initiate cooling directly from 350°C, ensuring rapid cooling and saving both time and effort

Safety

This series of equipment is equipped with multiple safety features, including self-diagnostic systems, overload protection for the refrigeration unit, high-pressure switches, overload relays, and high-pressure protection for the circulation system during high-temperature heating. These comprehensive safety measures ensure reliable and safe operation. The adaptive temperature control system continuously adjusts PID parameters based on specific process requirements (e.g., chemical reactions) to achieve optimal temperature control and reaction speed. By utilizing multiple temperature measurement points and analyzing temperature changes and rates in real-time, the system delivers precise temperature control.

Precise Temperature Measurement and Eco-Friendly Design

The circulator is equipped with both external and internal circulation temperature probes (PT100), ensuring precise calibration and consistent temperature control throughout the process. The equipment uses CFC- and HCFE-free refrigerants, meeting environmental standards while ensuring long-term, stable operation.

Durable and Reliable Construction

The liquid circulation and heating pipes are made from high-quality industrial-grade seamless 304 stainless steel with a thickness of 3.0MM, offering superior durability compared to standard decorative pipes. The refrigeration system utilizes a scroll compressor along with a high-temperature-resistant circulation pump, ensuring stable performance under both high and low-temperature conditions. The entire system operates with solid-state relays, eliminating sparks and noise, extending the lifespan of the equipment, and enhancing operational safety.

Wide Temperature Range and Efficient Control

This series of high and low temperature integrated circulators provides a wide working temperature range, from as low as -95°C to as high as 350°C, catering to a variety of complex experimental needs. Users can simultaneously monitor both the set temperature and the actual temperature, as well as the over-temperature alarm values, effectively preventing any abnormal temperature conditions. Additionally, the equipment features a quick liquid filling function, making the filling process simple and ensuring rapid cooling even under high-temperature conditions, further saving time in experiments and production.

Durable and Safe Design

The circulation and heating pipes are made of industrial-grade 304 stainless steel, and all connection hoses are insulated with stainless steel wire and insulation sleeves to mitigate the risks associated with high-temperature operations. The compressor lubricant is entirely synthetic, preventing carbonization and discoloration at high temperatures, further extending the equipment’s lifespan. The high-temperature-resistant circulation pump operates with low noise, no leakage, and reliable performance, ensuring stable operation over extended periods.

peculiarity

Eco Cooling: Copeland & Taikang

The refrigeration system uses an American Copeland compressor and a French Taikang high-temperature resistant circulation pump, offering stable performance. It adopts eco-friendly, CFC-free refrigerants, compliant with both EU and national standards.

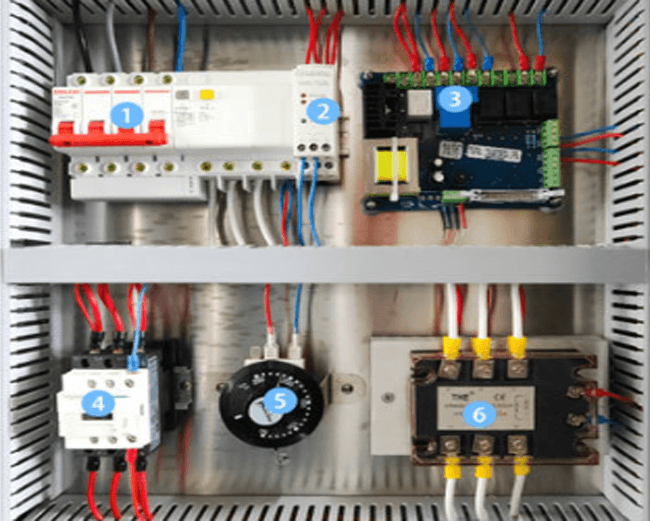

Safety-Certified Electrical Components

This equipment uses well-known brand electrical components that meet safety standards and can be equipped with explosion-proof distribution boxes.

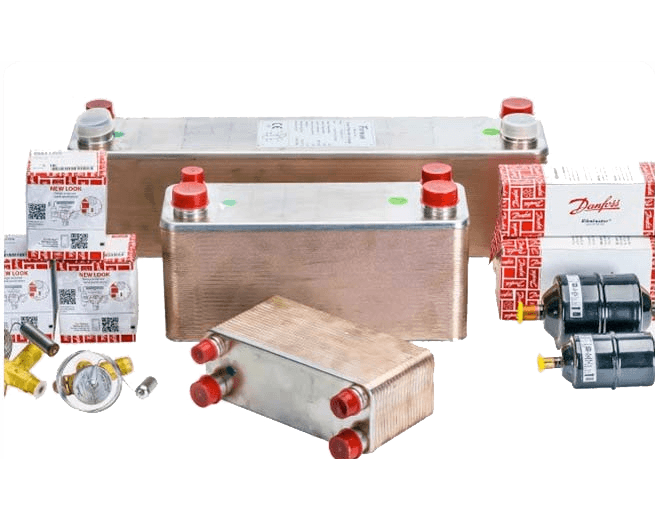

Compact, High-Efficiency Brazed Plate Heat Exchanger

The refrigeration uses a fully brazed plate heat exchanger, which is space-efficient and has high heat transfer efficiency, requiring less thermal oil.

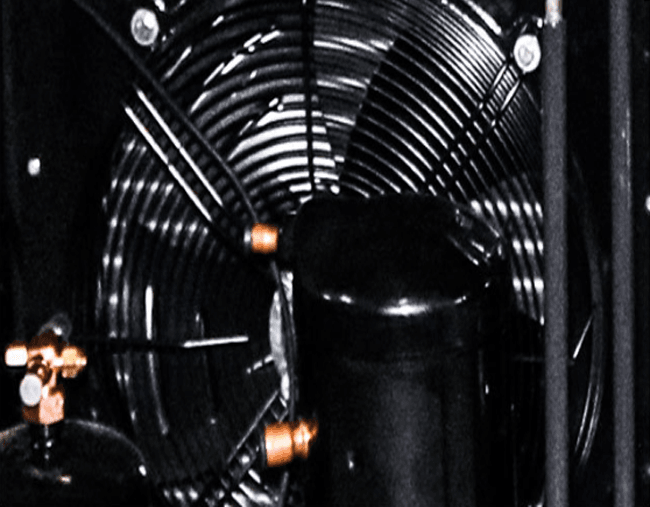

High-Efficiency Air-Cooled Condenser

Designed for superior heat dissipation and rapid cooling, our air-cooled condenser ensures optimal performance and fast temperature reduction