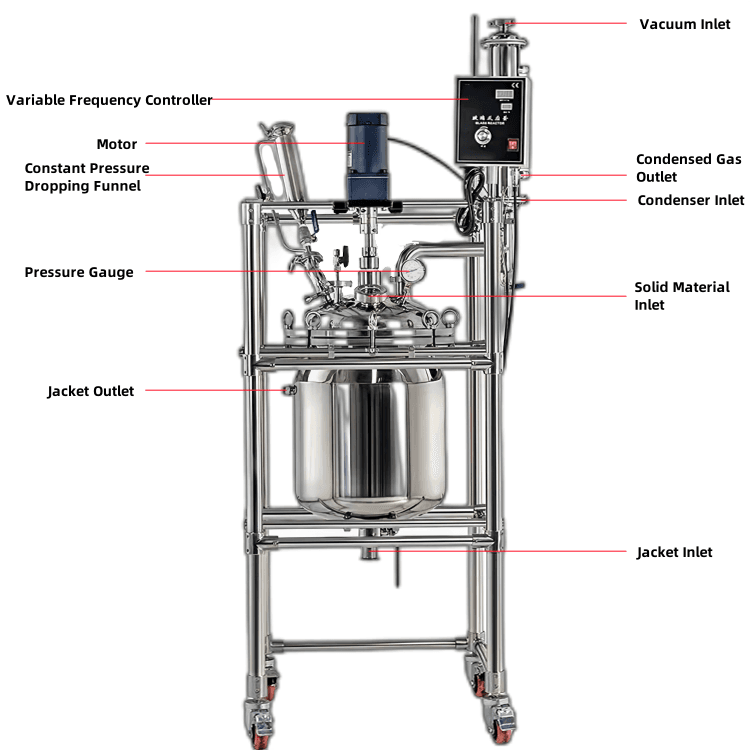

Detailed Description

Key Features

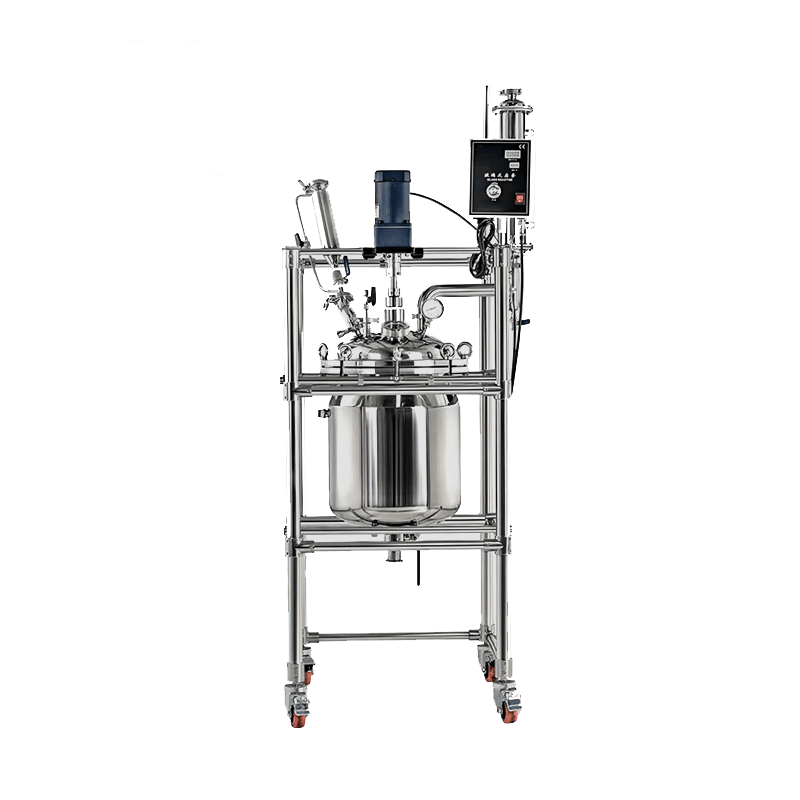

Large Capacity: 200L stainless steel reactor chamber suitable for mid-to-large scale reactions.

Material Options: Available in 304 or 316 stainless steel for enhanced chemical compatibility.

Digital Control: Features adjustable stirring speed and temperature display for precise reaction monitoring.

Pressure Tolerance: Designed for working pressures from 1 to 0.59 MPa, ensuring safe pressurized operations.

Durable Construction: Inner and outer walls are both 4 mm thick, adjustable to meet pressure demands.

Efficient Mixing: Fluorine-coated stainless steel agitator shaft provides corrosion-resistant and stable stirring at 0–450 RPM.

Customizable Design: Kettle diameter and shaft types can be tailored to your project needs.

Easy Discharge: Equipped with DN32 stainless steel ball valve for clean and efficient product discharge.

Technical Specifications

Reaction Volume: 200L

Material: 304 or 316 Stainless Steel (Optional)

Wall Thickness: Inner 4 mm / Outer 4 mm (Adjustable)

Motor Power: 750W

Rotation Speed: 0–450 RPM

Controller: Speed Adjustable, Digital Temperature Display

Kettle Diameter: Customizable

Working Pressure: 1 ~ 0.59 MPa

Agitator Shaft: Stainless Steel with Fluorine Coating

Discharge Valve: DN32 Ball Valve

Power Supply: 220V / 50Hz

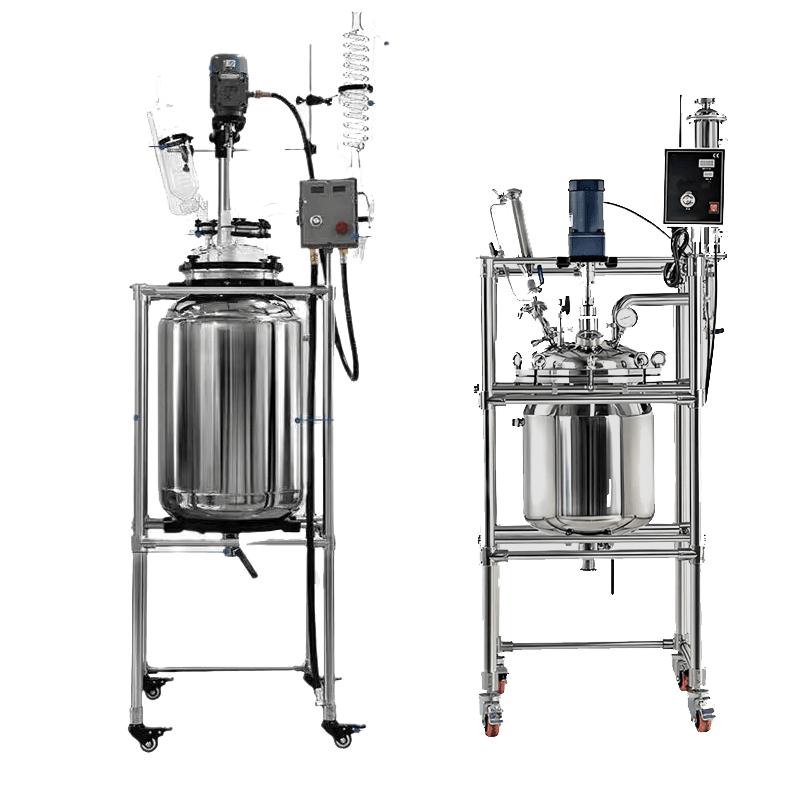

Compatible Equipment

Circulating Heating System – To provide uniform heating across the reactor jacket, maintaining consistent reaction temperature.

Vacuum Pump – Enables reduced-pressure reactions and degassing for sensitive compounds.

Condensation Coil – Useful for exothermic reactions or to recover solvents by condensing vapors.

Control Cabinet with PLC – For process automation and remote data monitoring.

Liquid Feeding Pump – Supports continuous feeding during long reactions, improving efficiency and safety.

Why Choose Our Stainless Steel Reactor

This 200L Stainless Steel Reactor is optimized for chemical synthesis, process development, and pilot-scale production where performance and durability are critical. Its flexible design accommodates different pressure levels and stirring requirements, while the digital display and fluorine-coated shaft ensure precision and chemical resistance. Whether you’re processing high-viscosity fluids or scaling up a formulation, this stainless steel reactor delivers reliable performance across the board.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More in Our Stainless Steel Reactor Category

Discover more models in our Stainless Steel Reactor collection.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKGF-5L | AKGF-10L | AKGF-20L | AKGF-30L | AKGF-50L | AKGF-100L | AKGF-200L |

|---|---|---|---|---|---|---|---|

| Reaction Volume (L) | 5 | 10 | 20 | 30 | 50 | 100 | 200 |

| Material | 304 (316) Stainless Steel (Optional) | ||||||

| Thickness | Inner wall 4mm, outer wall 4mm (Adjustable based on pressure) | ||||||

| Motor Power (W) | 120 | 200 | 250 | 250 | 400 | 400 | 750 |

| Rotation Speed | 0-450 RPM | ||||||

| Controller | Speed adjustment, digital temperature display | ||||||

| Kettle Diameter (mm) | Customized based on requirements | ||||||

| Working Pressure | (1~0.59Mpa) | ||||||

| Agitator Shaft | Stainless Steel coated with fluorine materials (Various types available) | ||||||

| Discharge Valve | DN32 Ball Valve | ||||||

| Power Supply | 220V/50Hz | ||||||

introduce

Application Scenarios

Pharmaceutical Synthesis

The stainless steel reactor is widely used in pharmaceutical manufacturing for synthesizing active pharmaceutical ingredients (APIs), where temperature precision and corrosion resistance are critical.Chemical Processing Plants

Ideal for mid-scale to industrial chemical production, the stainless steel reactor offers stable pressure control and durable construction for acid, base, or organic reactions.Pilot Plant Scale-Up

In R&D or pilot environments, the 200L stainless steel reactor bridges lab-scale and commercial production, allowing for reliable process scale-up with customizable stirring and heating options.Food and Beverage Additive Formulation

Suitable for emulsification, mixing, or thermal processing of food additives, leveraging the stainless steel reactor’s sanitary design and digital temperature control.Petrochemical Research

Used for catalyst testing, polymer synthesis, and reaction kinetics studies under controlled pressure and temperature in petrochemical R&D labs.Battery Materials and Nanomaterials Synthesis

Stainless steel reactors are preferred for high-purity synthesis of lithium battery components or nanomaterials due to their resistance to contamination and high thermal tolerance.Cosmetics and Personal Care Product Development

Efficiently mixes viscous formulations such as creams or gels, while maintaining product purity and consistent heating in cosmetic production trials.

peculiarity

“Stainless Steel Reactor Body” “High-Quality Stainless Steel Reactor Body” “Corrosion-Resistant and High-Temperature Resistant”

Stainless Steel Reactor LidGood Sealing PerformanceThe material is neither volatile nor flammable/explosive

Bottom Discharge Outlet” “Stainless Steel Discharge Outlet, corrosion-resistant and wear-resistant” “No dead angles inside the reactor, no residual liquid during discharge

“Visual Window” “High-Pressure Sealed Visual Window” “Provides a clear view of the reaction inside the reactor”