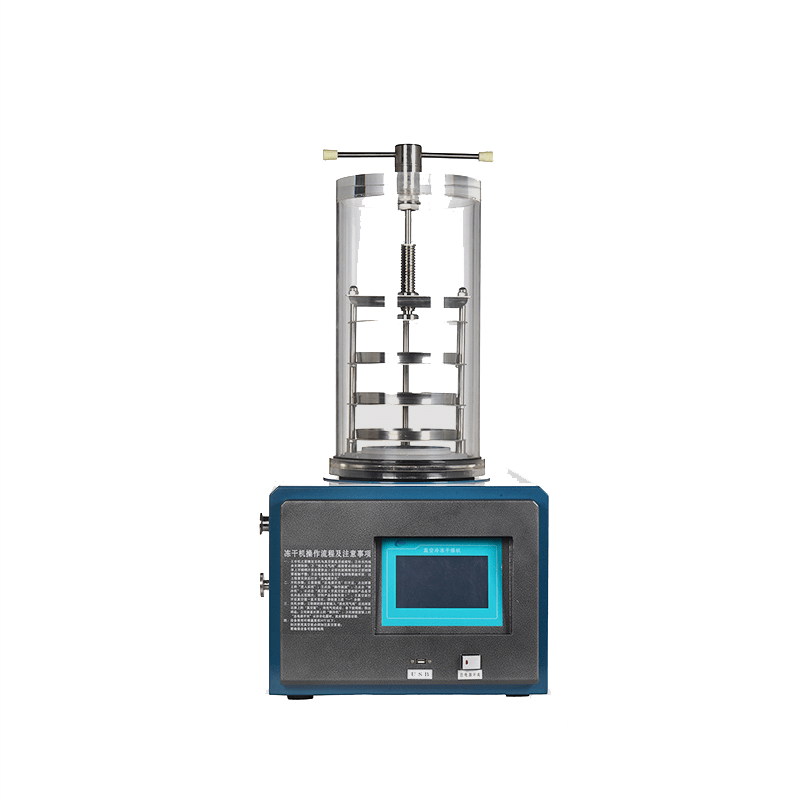

Detailed Description

Key Features of the Benchtop Top Press Vacuum Freeze Dryer

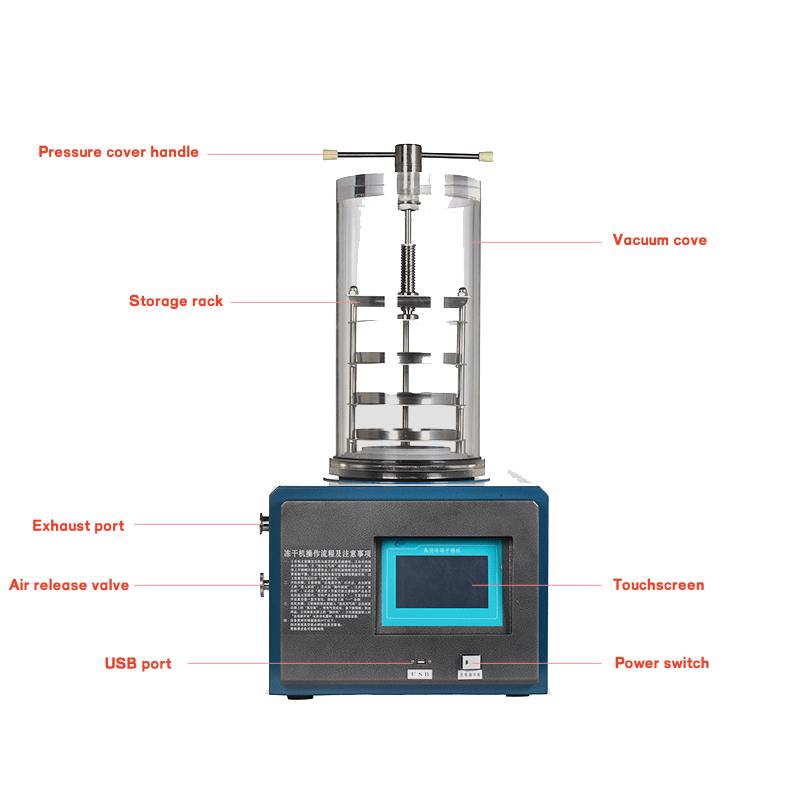

Cold Coil Cooling: Reaches -55°C (optional -80°C) for stable and rapid sublimation.

High Vacuum Performance: Achieves vacuum levels below 5Pa, ensuring thorough moisture removal.

Efficient Drying Rate: Handles 3–4kg of water extraction per 24 hours, ideal for small-batch applications.

Compact Tray Area: Offers 0.08m² of usable drying area with three φ180mm trays and 100mm max spacing.

Large Vial Capacity: Supports up to 920 vials (φ12mm) or 480 vials (φ16mm) for high-throughput processing.

Compact Form Factor: Dimensions of 520×600×400mm and weight of just 48kg make it suitable for any lab bench.

Cooling System: Air-cooled design with natural defrost mode reduces maintenance and operating costs.

Low Power Consumption: Operates efficiently at 950W using standard 220V laboratory power.

Safe and Stable: Designed for environments between 10°C–30°C with relative humidity ≤70%.

Technical Specifications

Model: Benchtop Top Press Vacuum Freeze Dryer

Additional Surface Area: 0.08 m²

Cold Coil Temperature: -55°C (optional -80°C)

Ultimate Vacuum: Below 5Pa (unloaded)

Pumping Speed: 2L/S

Water Extraction Capacity: 3–4 kg/24 h

Cooling Method: Air cooling

Defrost Mode: Natural defrost

Dimensions: 520×600×400 mm

Weight: 48 kg

Total Power: 950W

Material Trays: 3 trays, φ180mm, max press-fit spacing 100mm

Vial Support: φ12mm: 920 vials, φ16mm: 480 vials

Power Supply: 220V±10%, 50Hz

Operating Environment: 10°C–30°C, ≤70% RH, no explosive gases, conductive dust, or EMI

Storage Temperature: -40°C~50°C

Recommended Compatible Equipment

To enhance performance and workflow, this Benchtop Top Press Vacuum Freeze Dryer can be used with:

Oil-Free Vacuum Pump for clean and reliable vacuum generation

Pre-Cooling Freezer to shorten freezing time before drying

Vial Sealing Press for efficient post-drying vial closure

Cold Trap to capture and condense excess vapors

Inert Gas Inlet System for oxygen-sensitive sample drying

Compact and Precise Freeze-Drying for Laboratory Workflows

The Benchtop Top Press Vacuum Freeze Dryer is tailored for labs requiring precise, space-efficient freeze-drying. Its high vial capacity, consistent vacuum performance, and energy-saving design make it an excellent tool for small-batch research and production environments.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Discover More Vacuum Freeze Dryers for Laboratory Use

Explore more lab freeze dryers in our vacuum freeze dryer category to find the perfect fit for your application.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKGJ-10 Standard Model | AKGJ-10 Multi-branch Model | AKGJ-10 Press-fit Model | AKGJ-10 Multi-branch Press-fit Model |

|---|---|---|---|---|

| Addition Surface Area | 0.1m² | 0.1m² | 0.08m² | 0.08m² |

| Cold Coil Temperature | -55°C (unloaded), Optional -80°C (unloaded) | |||

| Ultimate Vacuum | Below 5Pa (unloaded) | |||

| Pumping Speed | 2L/S | |||

| Water Extraction Capacity | 3-4kg/24h | |||

| Cooling Method | Air cooling | |||

| Defrost Mode | Natural defrosting | |||

| Main Unit Weight | 48kg | |||

| Main Unit Dimensions | 520×600×400(mm) | |||

| Total Power | 950W | |||

| Material Tray | 4 trays, tray diameter φ180mm, tray spacing 70mm | 3 trays, tray diameter φ180mm, maximum press-fit spacing 100mm | ||

| Pear-shaped Flask | 8 pear-shaped flasks: 100ml, 150ml, 250ml, 500ml, 2 each | |||

| Flask Support Device | For φ12mm vials: 920 vials, For φ16mm vials: 480 vials | For φ12mm vials: 560 vials, For φ16mm vials: 285 vials | ||

| Operating Conditions/Environmental Temperature | 10°C~30°C | |||

| Relative Humidity | ≤70% | |||

| Power Supply Voltage | Single-phase 220V±10% 50Hz | |||

| Operating Environment | The operating environment should be free of conductive dust, explosive gases, and strong electromagnetic interference | |||

| Transportation Conditions/Environmental Temperature | -40°C~50°C | |||

introduce

Application Scenarios

Pharmaceutical Research and Development

Ideal for freeze-drying sensitive pharmaceutical compounds, such as vaccines and biologics. The precise control over freezing and drying processes ensures high product integrity and effective preservation of active ingredients.Biotechnology and Laboratory Applications

Suitable for laboratories focused on biotechnology research, including the preservation of microbial cultures, enzymes, and DNA samples. The efficient moisture removal enhances sample stability for further analysis.Food and Beverage Industry

In food processing, this freeze dryer is perfect for dehydrating fruits, vegetables, and other food products while maintaining taste, texture, and nutritional value. It’s particularly useful for creating freeze-dried meals and snacks.Chemical Analysis and Material Preservation

The vacuum freeze dryer is essential for preserving various chemical compounds and materials, such as polymers and specialty chemicals, by removing moisture without compromising their structure.Environmental and Field Research

In environmental science, this system can be used to dry samples from field research, such as soil and water samples, helping researchers analyze substances in their natural state without degradation.

peculiarity

Exclusive Confidential Noise-Canceling Technology

Low decibel / Non-intrusive / Use with confidence

Say goodbye to inferior aluminum cores

Prone to oxidation / Poor conductivity / Short lifespan

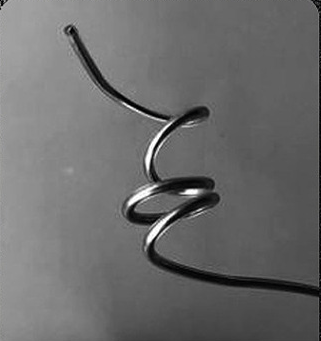

Made with thick copper wire

Low heat generation / Powerful performance / Stable operation

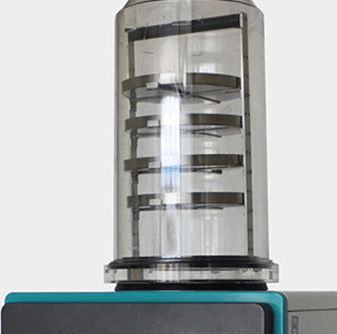

High-Transparency Freeze-Drying Chamber

Scratch-Resistant and Durable / Superior Quality for Long-lasting Use