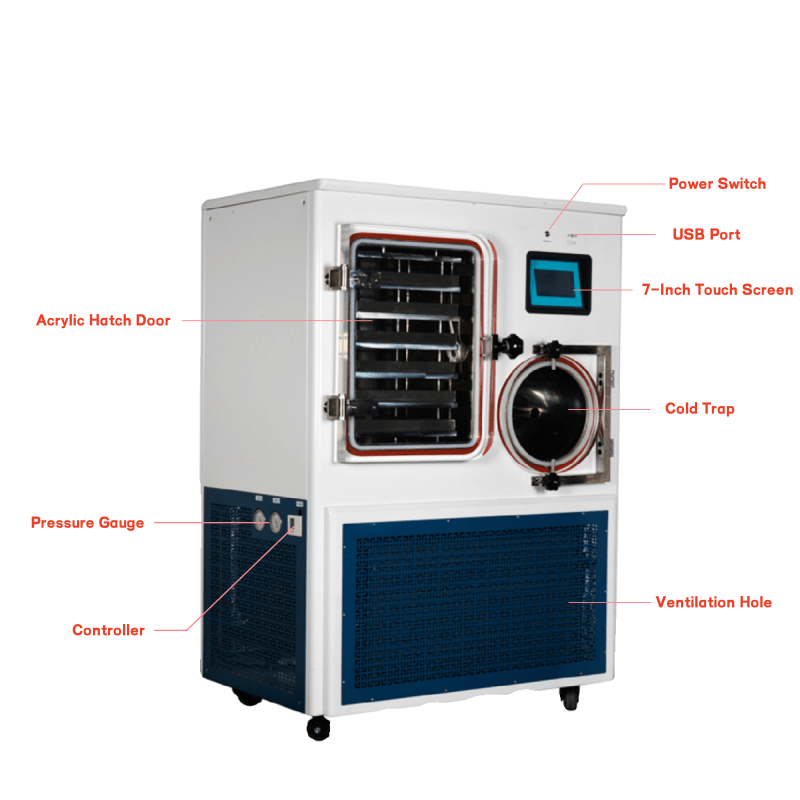

Detailed Description

Main Features

15L Tray Capacity: Suitable for medium-scale lab freeze drying and pilot production.

Wide Shelf Temperature Range (-50°C to 70°C): Supports different sample types and drying stages.

High Water Capture Efficiency (15kg/24H): Ensures fast drying cycles and stable performance.

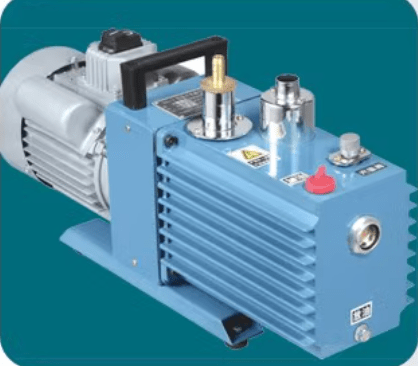

Powerful Vacuum Pump (16L/S): Provides strong vacuum for effective sublimation.

Versatile Vial Compatibility: Supports 12mm, 16mm, and 22mm vials, up to 7,380 vials per run.

Air Cooling System: Reliable and energy-efficient cooling for stable operation.

High-Temperature Defrost Mode: Easy maintenance and faster defrost cycles.

Stainless Steel 304 Construction: Corrosion-resistant and durable for long-term use.

Clear Observation Window: Acrylic window for real-time monitoring during freeze drying.

Technical Specifications

Model: AKGJ-100

Freeze-Drying Area: 1m²

Water Capture Capacity: 15kg/24H

Tray Solution Volume: 15L

Vials (12mm): 7380 pcs

Vials (16mm): 3880 pcs

Vials (22mm): 2040 pcs

Shelf Temperature: -50°C ~ 70°C

Cold Trap Temperature: -80°C (unloaded)

Ultimate Vacuum: 2PA (unloaded)

Cooling Method: Air cooling

Defrost Mode: High-temperature defrost

Storage/Transport Environment: -40°C ~ 50°C, RH ≤70%

Operating Environment Temperature: 10°C ~ 35°C

Dimensions (mm): 1400×850×1725

Vacuum Pump: 16L/S

Total Power: 6.5KW

Material: 304 stainless steel

Observation Window: Acrylic

Compatible Equipment

Enhance performance with compatible laboratory equipment:

Vacuum Pumps: Essential for achieving stable vacuum levels during freeze drying.

Cooling Systems: Additional chillers or cooling units for large-scale operations.

Temperature Controllers: Ensure precise shelf and trap temperature control.

Vial Holders & Trays: Secure sample placement and stable loading.

Product Highlights

High-Efficiency Freeze Drying: 15kg/24H water capture and 15L tray capacity ensure fast and stable drying cycles.

Precision Temperature Control: -50°C to 70°C shelf temperature range for accurate and reproducible drying results.

Pilot-Scale Lyophilizer: Suitable for laboratory research, pilot production, and small batch manufacturing.

Direct Manufacturer Supply: Competitive pricing, OEM/ODM customization, and fast global delivery.

Why Buy from Us

Direct China Manufacturer & Supplier: Skip middlemen and enjoy competitive pricing.

OEM/ODM Customization: Tailored solutions for pharmaceutical, biotech, and food industries.

Technical Support & Warranty: Professional guidance throughout installation and operation.

Fast Global Shipping: Efficient delivery to labs and pilot plants worldwide.

Request a Quote or Datasheet: Get precise pricing and specifications for your application.

Watch Product Demonstrations

Explore real-world performance and applications in our demo videos.

FAQ

Q1: What is the tray capacity of AKGJ-100?

A1: The AKGJ-100 features a 15L tray capacity, suitable for medium-scale lab and pilot freeze drying.

Q2: What is the shelf temperature range?

A2: Shelf temperature ranges from -50°C to 70°C, supporting various sample types and drying stages.

Q3: Is the AKGJ-100 suitable for pharmaceuticals and biologics?

A3: Yes, it is designed for pharmaceutical, biotech, and food preservation applications, ensuring precise and contamination-free drying.

Q4: What is the difference between a manual freeze dryer and an automated freeze dryer?

A4: Manual freeze dryers are more cost-effective and easier to maintain, suitable for moderate workloads. Automated systems offer higher automation, monitoring, and large-scale production efficiency.

Q5: How to choose between 15L and 25L freeze dryer?

A5: Choose 15L for lab research and pilot production; choose 25L for higher throughput and larger batch sizes. Consider your sample volume, production scale, and budget.

Q6: How can I buy or request a quote?

A6: Contact us directly through our inquiry form or WhatsApp. We provide factory-direct pricing, OEM/ODM support, and datasheets.

Q7: Where can I learn more about freeze drying and its applications?

A7: You can read a comprehensive overview on Freeze drying – Wikipedia, including principles, components, and typical laboratory uses.

Related Products

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKGJ-20 | AKGJ-30 | AKGJ-50 | AKGJ-100 |

|---|---|---|---|---|

| Specification | Silicone Oil Heating | Silicone Oil or Electric Heating | Silicone Oil or Electric Heating | Silicone Oil Heating |

| Freeze-drying Area | 0.3m² | 0.4m² | 0.6m² | 1m² |

| Water Capture Capacity | 4kg/24H | 6kg/24H | 8kg/24H | 15kg/24H |

| Tray Solution Volume | 3L | 5L | 6L | 15L |

| Vials (12mm) | 1300 pcs | 2600 pcs | 3690 pcs | 7380 pcs |

| Vials (16mm) | 810 pcs | 1620 pcs | 1940 pcs | 3880 pcs |

| Vials (22mm) | 430 pcs | 860 pcs | 1020 pcs | 2040 pcs |

| Shelf Length (mm) | 265 | 300 | 320 | 360 |

| Shelf Width (mm) | 395 | 345 | 320 | 480 |

| Shelf Spacing | 50mm | 50mm | 70mm | 100mm |

| Sample Trays | 3 | 4 | 4 | 6 |

| Shelf Temperature | -50°C~70°C | -50°C~70°C | -50°C~70°C | -50°C~70°C |

| Cold Trap Temperature | -70°C (unloaded) | -70°C (unloaded) | -80°C (unloaded) | -80°C (unloaded) |

| Ultimate Vacuum | 2PA (unloaded) | |||

| Cooling Method | Air Cooling | |||

| Defrost Mode | High-Temperature Defrost | |||

| Storage/Transport Environment | -40°C~50°C | |||

| Relative Humidity | ≤70% | |||

| Operating Environment Temperature | 10°C~35°C | |||

| Dimensions (mm) | 594×718×1400 | 880×735×1320 | 1100×812×1420 | 1400×850×1725 |

| Vacuum Pump | 4L/S | 6L/S | 8L/S | 16L/S |

| Total Weight | 200KG | 400KG | 500KG | 600KG |

| Total Power | 3.0KW | 4.5KW | 5.5KW | 6.5KW |

| Main Material | 304 Stainless Steel | |||

| Observation Window Material | Acrylic | |||

introduce

Application Scenarios

Pharmaceutical Laboratories

Used for drying vaccines, injectable solutions, and active pharmaceutical ingredients (APIs). The AKGJ-100 Vacuum Freeze Dryer ensures product sterility, stability, and extended shelf life without compromising molecular integrity.Biological Research Centers

Ideal for preserving enzymes, proteins, tissues, and microbial cultures. Its low-temperature and high-vacuum capabilities help maintain biological activity and structure during long-term storage.Food and Beverage Industry

Enables gentle dehydration of heat-sensitive food products such as fruits, coffee, herbs, dairy, and snacks. The Vacuum Freeze Dryer preserves natural flavors, colors, and nutrients, making it suitable for premium product manufacturing.Environmental Testing and Soil Labs

Facilitates the preservation of water and soil samples without altering chemical composition. Its precise drying process ensures accurate downstream analysis.Biotechnology Startups and Pilot-Scale Production

Offers reliable freeze drying for experimental materials or limited-scale product batches. Its flexible parameters make it ideal for R&D, testing, and process optimization.

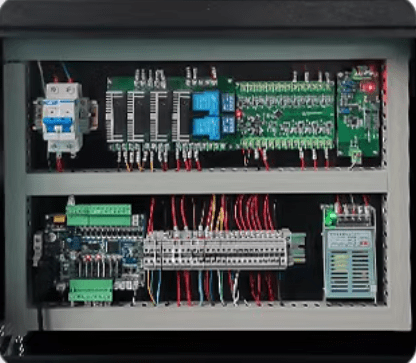

peculiarity

Multi-functional Control System

Versatile Adjustments High Freeze-drying Efficiency Energy-saving and Power-efficient

Branded Vacuum Pump

Pure Copper Motor Continuous Operation Without Overheating No Oil Backflow, Prevents Material Contamination

European DANFOSS Compressor

Low Noise, High Power, Long Lifespan Excellent Cooling Performance Enhanced Stability

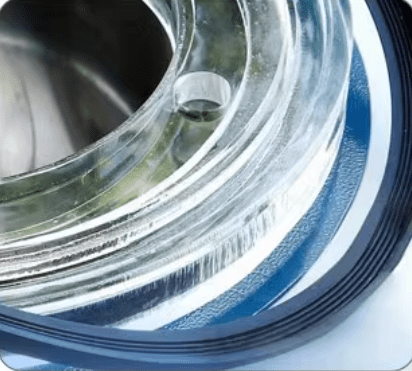

Silicone Sealing Ring

Ensures Vacuum Operation of the Equipment Anti-Aging, Safe and Reliable to Use