Detailed Description

Advantages

Preserves Quality and Nutrients: Maintains natural color, aroma, and taste of samples.

Protects Proteins and Bioactive Compounds: Freeze-drying preserves sensitive enzymes and proteins.

Reduces Weight and Volume: Loss of 70–90% weight and >50% volume lowers storage and transport costs.

Extends Shelf Life: Removes 95–99% moisture, inhibiting microbial growth for long-term storage.

Small Industrial & Laboratory Ready: Compact design suitable for pilot-scale production and lab use.

Direct from Manufacturer: Available for sale with reliable technical support and competitive pricing.

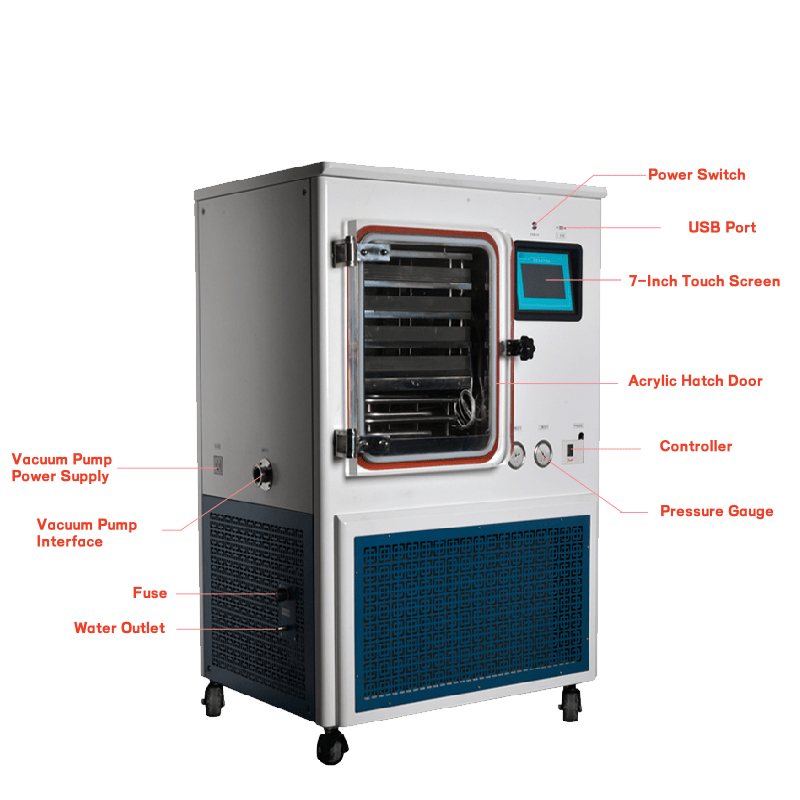

Key Features

Dual Heating System: Silicone oil or electric heating for precise thermal control.

Freeze-Drying Area: 0.4 m² with 4 adjustable trays for small batch processing.

Water Capture Capacity: Up to 6 kg per 24 hours via high-efficiency cold trap.

Shelf Temperature Range: -50°C to 70°C for sensitive materials.

Vial Capacity: 12 mm (2600 pcs), 16 mm (1620 pcs), 22 mm (860 pcs).

Ultimate Vacuum: 2 Pa (unloaded) for superior drying efficiency.

Air-Cooled Operation: Energy-efficient and reliable.

High-Temperature Defrost Mode: Easy cleaning and maintenance.

Observation Window: Acrylic window to monitor drying in real time.

Small Industrial / Laboratory Application: Ideal for pilot production, food research, and biotechnology labs.

Technical Specifications

Model: AKGJ-30

Heating Type: Silicone Oil or Electric Heating

Freeze-Drying Area: 0.4 m²

Water Capture Capacity: 6 kg/24H

Tray Solution Volume: 5 L

Vial Capacity: 12 mm (2600 pcs), 16 mm (1620 pcs), 22 mm (860 pcs)

Shelf Size: 300 × 345 mm

Shelf Spacing: 50 mm

Number of Trays: 4

Shelf Temperature Range: -50°C to 70°C

Cold Trap Temperature: -70°C (unloaded)

Ultimate Vacuum: 2 Pa (unloaded)

Cooling Method: Air Cooling

Defrost Mode: High-Temperature Defrost

Operating Temperature: 10°C to 35°C

Storage/Transport Temperature: -40°C to 50°C

Relative Humidity: ≤70%

Dimensions: 880 × 735 × 1320 mm

Vacuum Pump Capacity: 6 L/S

Total Weight: 400 kg

Total Power: 4.5 kW

Main Material: 304 Stainless Steel

Observation Window: Acrylic

Compatible Equipment

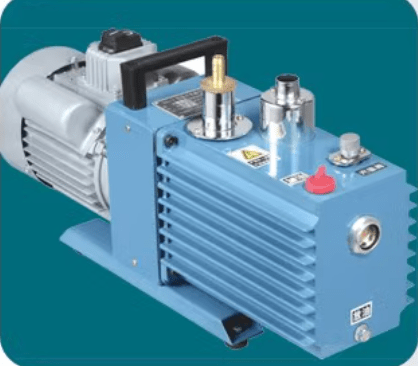

Vacuum Pumps: Dry or oil-sealed for stable vacuum levels.

Cold Trap Pre-Coolers: Boost ice trapping efficiency.

Moisture Analyzers: Verify dryness after freeze-drying.

Inert Gas Purge Systems: For oxygen-sensitive samples.

Heat Sealers: Seal vials after drying.

Why Choose AKGJ-30

Direct manufacturer and supplier with competitive pricing.

Reliable silicone oil heating for consistent thermal control.

Compact, durable design for small industrial batches and lab use.

High vacuum efficiency for superior freeze-drying performance.

Full technical support ensures reliable and continuous operation.

Learn About the Freeze-Drying Process

The AKGJ-30 Silicone Oil Heating Freeze Dryer is designed for food, pharmaceutical, and laboratory samples. Its freeze-drying process — freezing → vacuum → silicone oil heating → sublimation — preserves nutrients, flavor, and structure. For more detailed technical information, visit Freeze drying on Wikipedia.

Explore More Industrial Freeze Dryers

Browse our Vacuum Freeze Dryer collection for additional small-scale industrial freeze drying solutions:

AKGJ-100L Vacuum Freeze Dryer – Large capacity industrial freeze dryer for pilot and production use

50L Industrial Freeze Dryer for Sale – Compact industrial solution for small-scale production

- AKGJ-20 Small Vacuum Freeze Dryer – Ideal for laboratory and pilot-scale applications

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKGJ-20 | AKGJ-30 | AKGJ-50 | AKGJ-100 |

|---|---|---|---|---|

| Specification | Silicone Oil Heating | Silicone Oil or Electric Heating | Silicone Oil or Electric Heating | Silicone Oil Heating |

| Freeze-drying Area | 0.3m² | 0.4m² | 0.6m² | 1m² |

| Water Capture Capacity | 4kg/24H | 6kg/24H | 8kg/24H | 15kg/24H |

| Tray Solution Volume | 3L | 5L | 6L | 15L |

| Vials (12mm) | 1300 pcs | 2600 pcs | 3690 pcs | 7380 pcs |

| Vials (16mm) | 810 pcs | 1620 pcs | 1940 pcs | 3880 pcs |

| Vials (22mm) | 430 pcs | 860 pcs | 1020 pcs | 2040 pcs |

| Shelf Length (mm) | 265 | 300 | 320 | 360 |

| Shelf Width (mm) | 395 | 345 | 320 | 480 |

| Shelf Spacing | 50mm | 50mm | 70mm | 100mm |

| Sample Trays | 3 | 4 | 4 | 6 |

| Shelf Temperature | -50°C~70°C | -50°C~70°C | -50°C~70°C | -50°C~70°C |

| Cold Trap Temperature | -70°C (unloaded) | -70°C (unloaded) | -80°C (unloaded) | -80°C (unloaded) |

| Ultimate Vacuum | 2PA (unloaded) | |||

| Cooling Method | Air Cooling | |||

| Defrost Mode | High-Temperature Defrost | |||

| Storage/Transport Environment | -40°C~50°C | |||

| Relative Humidity | ≤70% | |||

| Operating Environment Temperature | 10°C~35°C | |||

| Dimensions (mm) | 594×718×1400 | 880×735×1320 | 1100×812×1420 | 1400×850×1725 |

| Vacuum Pump | 4L/S | 6L/S | 8L/S | 16L/S |

| Total Weight | 200KG | 400KG | 500KG | 600KG |

| Total Power | 3.0KW | 4.5KW | 5.5KW | 6.5KW |

| Main Material | 304 Stainless Steel | |||

| Observation Window Material | Acrylic | |||

introduce

Application Scenarios

Home Food Preservation

Ideal for preserving a wide range of food items such as fruits, vegetables, meats, and herbs. The AKGJ-30 Silicone Oil Heating Freeze Dryer ensures the retention of nutrients, flavor, and texture, providing long-term storage without refrigeration.Small-Scale Laboratories

Perfect for small labs requiring the freeze-drying of biological, pharmaceutical, or chemical samples. With its precise temperature control and vacuum capabilities, it helps maintain the integrity of sensitive materials.Research Facilities

Researchers can use the AKGJ-30 for drying delicate scientific samples, ensuring minimal degradation and preserving the structure of organic compounds. This dryer is well-suited for both experimental work and sample preparation in academic and industrial research.Herbal and Nutraceutical Applications

The freeze dryer is excellent for preserving herbal products and nutraceuticals. It retains the active compounds and nutrients in herbs and supplements, extending their shelf life without compromising quality.Emergency and Survival Food Preparation

For emergency preparedness or survival food production, the AKGJ-30 can efficiently freeze-dry meals and ingredients, ensuring a long shelf life without refrigeration while maintaining the food’s original nutritional content.

peculiarity

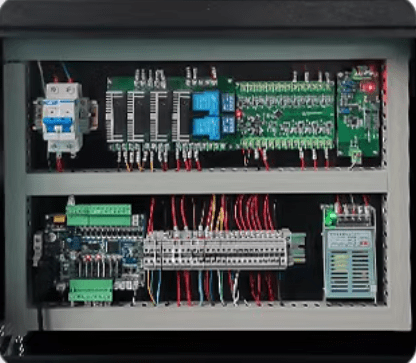

Multi-functional Control System

Versatile Adjustments High Freeze-drying Efficiency Energy-saving and Power-efficient

Branded Vacuum Pump

Pure Copper Motor Continuous Operation Without Overheating No Oil Backflow, Prevents Material Contamination

European DANFOSS Compressor

Low Noise, High Power, Long Lifespan Excellent Cooling Performance Enhanced Stability

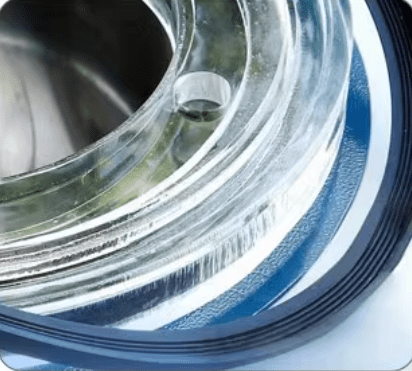

Silicone Sealing Ring

Ensures Vacuum Operation of the Equipment Anti-Aging, Safe and Reliable to Use