Detailed Description

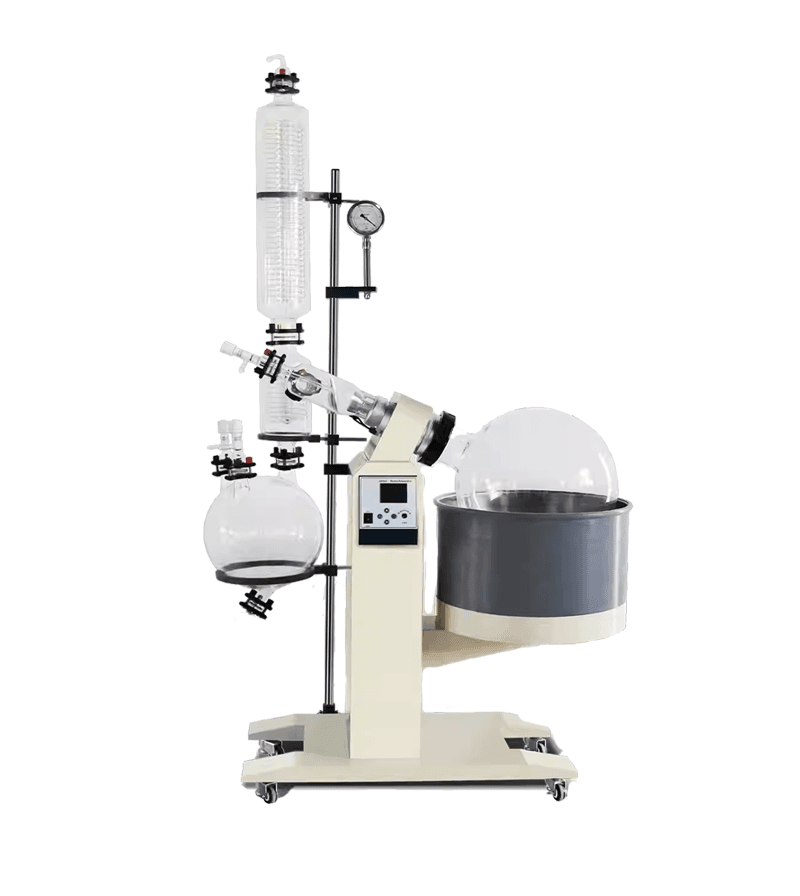

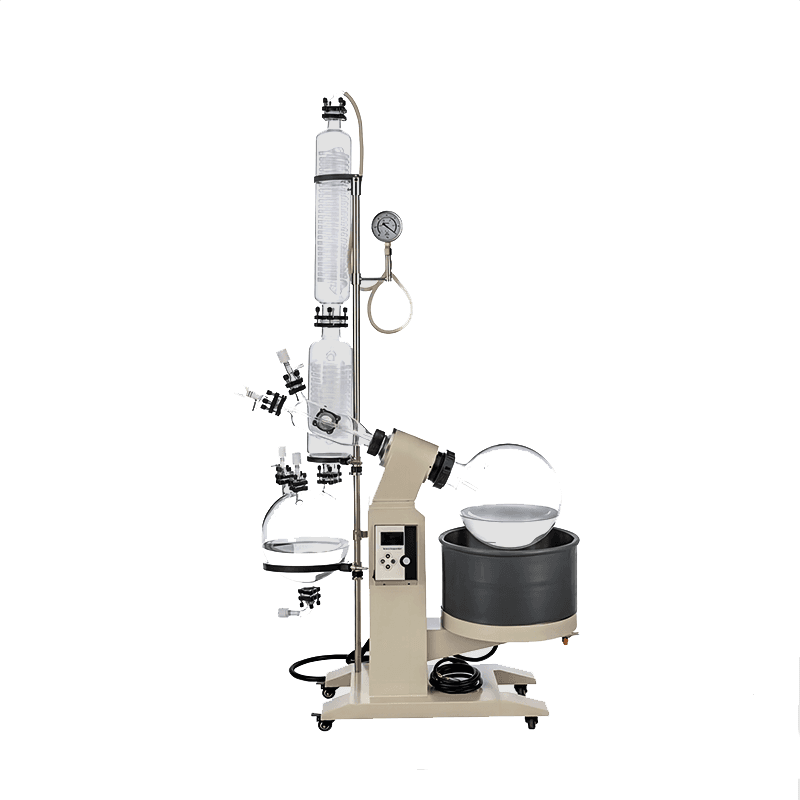

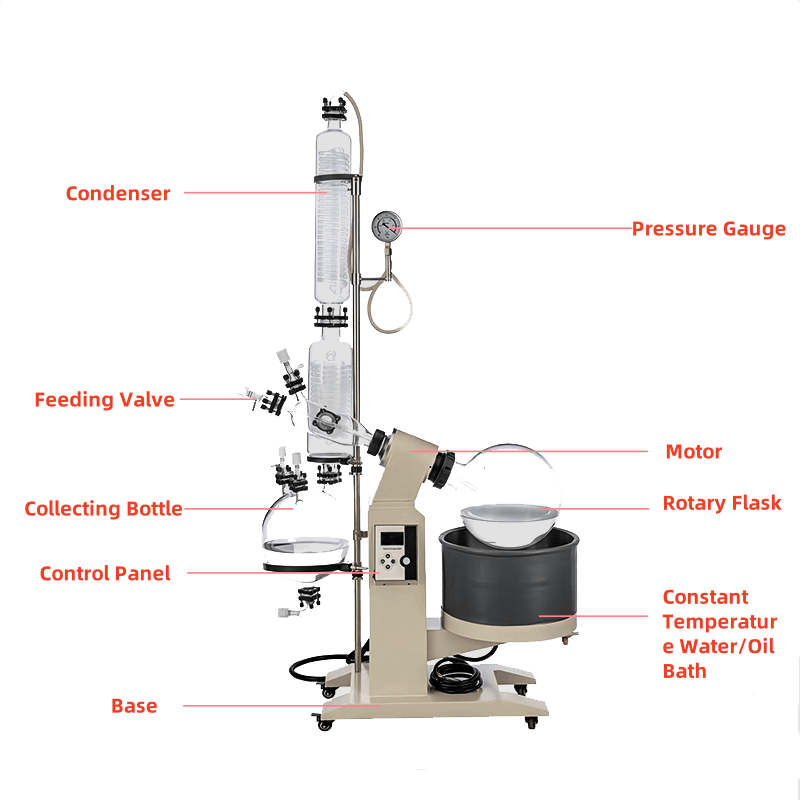

Key Features of the Rotary Evaporator Distillation System

The rotary evaporator distillation system includes a large 20L evaporation flask (φ355mm / φ95 flange) and a 10L collection flask, ideal for high-volume rotary evaporator distillation applications.

Powerful 5000W heating power supports rapid solvent evaporation during rotary evaporator distillation operations.

Rotating speed adjustable from 0 to 120 rpm for precise control during rotary evaporator distillation.

Temperature control from room temperature to 180°C with ±1°C accuracy ensures consistent rotary evaporator distillation results.

Vacuum degree of 0.095 MPa maximizes efficiency in rotary evaporator distillation by lowering solvent boiling points.

150mm bath lifting stroke facilitates easy loading and unloading during rotary evaporator distillation tasks.

High-efficiency condenser with 0.94㎡ area and multiple flange ports optimize condensation in rotary evaporator distillation.

Glass and Teflon valves ensure secure vacuum operation throughout rotary evaporator distillation.

Technical Specifications

Voltage / Frequency: 220V / 50Hz

Total Power: 5180W

Rotating Motor Power: 60W / 1/5 HP

Lifting Motor Power: EX120W

Heating Power: 5000W

Vacuum Degree: 0.095 MPa

Evaporation Flask Capacity: 20L (φ355mm / φ95 flange)

Collection Flask Capacity: 10L (φ280mm + φ60 flange + φ50 flange)

Rotating Speed: 0–120 rpm/min

Temperature Range: Room Temperature to 180°C

Temperature Accuracy: ±1°C

Bath Lifting Stroke: 150mm

Condenser Dimensions: φ130 × 700mm

Condenser Area: 0.94㎡ (0.46 + 0.48)

Gas Collection Bottle Flange Ports: Left φ35, Top Middle φ35, Side Middle φ60, Right Middle φ60

Exhaust Valve: φ35 flange ×2, Glass + Teflon Valve, Exhaust Nozzle (Bola Connector) φ12mm

Discharge Valve: φ50 flange, Side Nozzle (Bola Connector) φ20mm, Height 210mm

Vacuum Exhaust Head: φ60 glass flange, Exhaust Nozzle φ10mm

Condenser Coil Circulation Ports: Bola Connector φ16mm

Boiler Size / Volume: φ450 × 260mm, Approx. 41L

Overall Dimensions (W×D×H): 1210 × 610 × 2170 mm

Net Weight: 84KG

Packing Size: 1050 × 530 × 1210 mm, Wooden Box

Packing Weight: 116KG

Compatible Equipment for Enhanced Rotary Evaporator Distillation

Vacuum Pumps are essential to maintain optimal vacuum degree during rotary evaporator distillation, improving solvent evaporation efficiency.

Cooling Circulators provide stable temperature control for condenser coils in rotary evaporator distillation.

Magnetic Stirrers ensure uniform mixing of samples in rotary evaporator distillation for consistent evaporation.

Solvent Recovery Systems capture evaporated solvents during rotary evaporator distillation, enhancing sustainability.

Compatible Glassware Sets tailored for rotary evaporator distillation improve operational flexibility.

Why Choose This Rotary Evaporator Distillation System

This rotary evaporator distillation model offers a combination of large capacity, high power, and precise control to meet demanding laboratory rotary evaporator distillation needs. With advanced vacuum control, robust construction, and adjustable speed and temperature settings, this rotary evaporator distillation system maximizes evaporation efficiency and safety. The user-friendly bath lifting mechanism and versatile flange design support diverse rotary evaporator distillation applications with ease.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Cooling Solutions

Explore more models in our rotary evaporator distillation category for advanced rotary evaporator distillation solutions tailored for your lab.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKR-1010 | AKR-1020 | AKR-1050 |

|---|---|---|---|

| Voltage Frequency | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Power | 3180W | 5180W | 6780W |

| Rotating Motor Power | 60W/1/5 | 60W/1/5 | 100W/1/5 |

| Lifting Motor Power | EX120W | EX120W | EX180W |

| Heating Power | 3000W | 5000W | 6500W |

| Vacuum Degree | 0.095Mpa | 0.095Mpa | 0.095Mpa |

| Evaporation Capacity | 10L φ280mm/φ95 Flange | 20L φ355mm/φ95 Flange | 50L φ470mm/φ125 Flange |

| Collection Capacity | 5L φ230mm + φ60 Flange + φ50 Flange | 10L φ280mm + φ60 Flange + φ50 Flange | 20L φ355mm + φ60 Flange + φ50 Flange |

| Rotation Speed | 0-120rpm/min | 0-120rpm/min | 0-120rpm/min |

| Temperature Range | Room temperature to 180°C | Room temperature to 180°C | Room temperature to 180°C |

| Temperature Accuracy | ±1°C | ±1°C | ±1°C |

| Bath Lifting Stroke | 190mm | 150mm | 215mm |

| Condenser Dimensions | Main: φ120×620mm, Top: φ60 Flange, Bottom: φ80 Flange | Main: φ130×700mm, Top: φ60 Flange, Bottom: φ80 Flange | Main: φ160×835mm, Top: φ60 Flange, Bottom: φ80 Flange |

| Condenser Area | 0.51 (0.33 + 0.18)m² | 0.94 (0.46 + 0.48)m² | 1.44 (0.95 + 0.49)m² |

| Gas Collection Bottle | Left φ35 Flange, Top φ35 Flange, Side φ60 Flange, Right φ60 Flange | Left φ35 Flange, Top Middle φ35 Flange, Side Middle φ60 Flange, Right Middle φ60 Flange | Left Middle φ35 Flange, Top Middle φ35 Flange, Side Middle φ60 Flange, Right Middle φ70 Flange |

| Exhaust Valve | φ35 Flange ×2, Glass + Teflon Valve, Exhaust Nozzle (Bola Connector) Outer Diameter φ12mm | φ35 Flange ×2, Glass + Teflon Valve, Exhaust Nozzle (Bola Connector) Outer Diameter φ12mm | φ35 Flange ×2, Glass + Teflon Valve, Exhaust Nozzle (Bola Connector) Outer Diameter φ12mm |

| Discharge Valve | φ50 Flange, Side Discharge Nozzle (Bola Connector) Outer Diameter φ20mm, Height 210mm | φ50 Flange, Side Discharge Nozzle (Bola Connector) Outer Diameter φ20mm, Height 210mm | φ50 Flange, Side Discharge Nozzle (Bola Connector) Outer Diameter φ20mm, Height 300mm |

| Vacuum Exhaust Head | φ60 Flange Glass Exhaust Head, Exhaust Nozzle (Bola Connector) Outer Diameter φ10mm | φ60 Flange Glass Exhaust Head, Exhaust Nozzle (Bola Connector) Outer Diameter φ10mm | φ60 Flange Glass Exhaust Head, Exhaust Nozzle (Bola Connector) Outer Diameter φ10mm |

| Condenser Coil Inlet/Outlet/Circulation Nozzle | Bola Connector Outer Diameter φ16mm | Bola Connector Outer Diameter φ16mm | Bola Connector Outer Diameter φ16mm |

| Boiler Dimensions/Volume | φ350×220mm, Approx. 21L | φ450×260mm, Approx. 41L | φ550×320mm, Approx. 76L |

| Overall Dimensions | 1130×470×1940mm (W×D×H) | 1210×610×2170mm (W×D×H) | 1390×700×2300mm (W×D×H) |

| Net Weight | 70KG | 84KG | 103KG |

| Packing Size | 980×520×1190mm, Wooden Box | 1050×530×1210mm, Wooden Box | 1230×630×1420mm, Wooden Box |

| Packing Volume | 0.61m³ | 0.68m³ | 1.1m³ |

| Packing Weight | 107KG | 116KG | 148KG |

introduce

Application Scenarios

Chemical Synthesis and Purification

Used to efficiently remove solvents after chemical reactions, isolating high-purity compounds through precise rotary evaporator distillation.Pharmaceutical Research

Ideal for concentrating drug formulations and extracting active pharmaceutical ingredients with controlled temperature and vacuum.Food and Beverage Industry

Employed to extract natural flavors, concentrate food extracts, and recover solvents safely during product development.Environmental Analysis

Useful for concentrating environmental samples, enabling sensitive pollutant detection and analysis.Material Science

Applied in polymer preparation and purification of intermediates by removing solvents with minimal sample degradation.Academic and Industrial Research

Commonly used in laboratories for various distillation and solvent recovery tasks requiring accurate temperature and vacuum control.

peculiarity

Stainless Steel + PTFE Composite Pot

This pot combines the durability of stainless steel with the non-stick properties of PTFE (Teflon), offering superior resistance to chemical reactions and easy maintenance. Ideal for various applications requiring a high-performance, non-reactive surface.

PTFE + Imported Fluororubber Combination

This combination utilizes PTFE (Teflon) and high-quality imported fluororubber to provide superior sealing performance. It offers excellent chemical resistance and durability, ensuring reliable operation under various conditions.

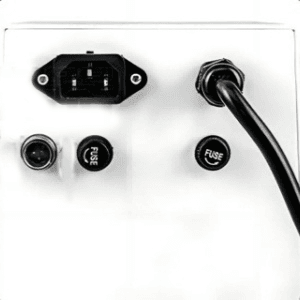

Power Plug and Fuse Switch

The device features a power plug for connection and a fuse switch for protection. The fuse switch ensures safety by protecting the equipment from electrical faults and overloads.

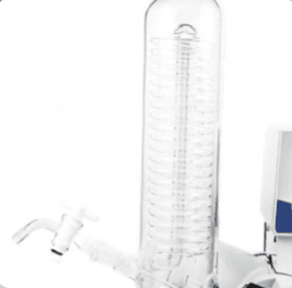

Vertical Double-Layer Serpentine Coil

This design features a vertical double-layer serpentine coil that ensures efficient heat exchange and high recovery rates. The compact and effective coil structure enhances overall performance and thermal efficiency.