Detailed Description

Key Features of the Rotovap Distillation System

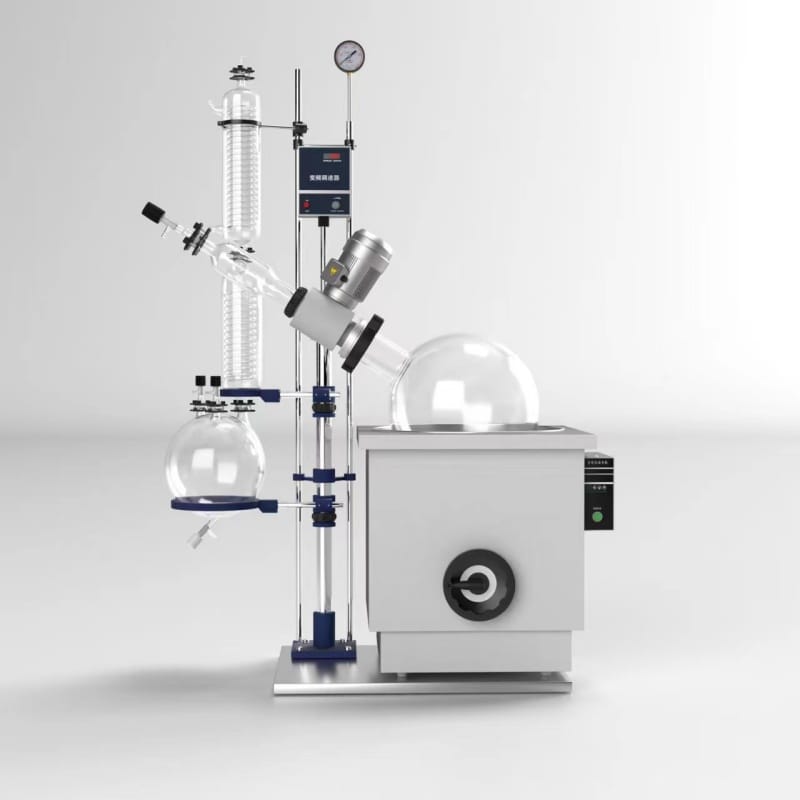

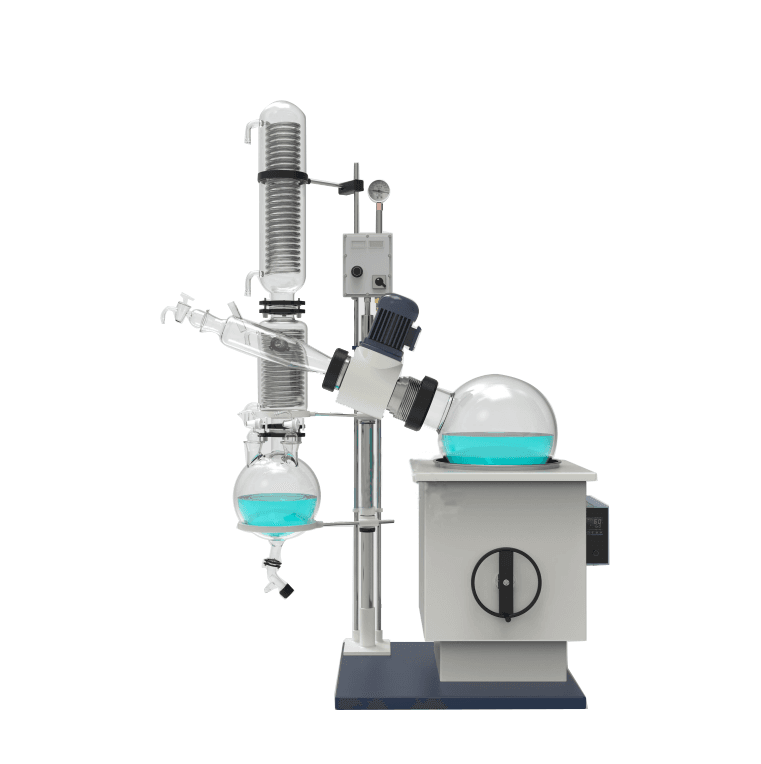

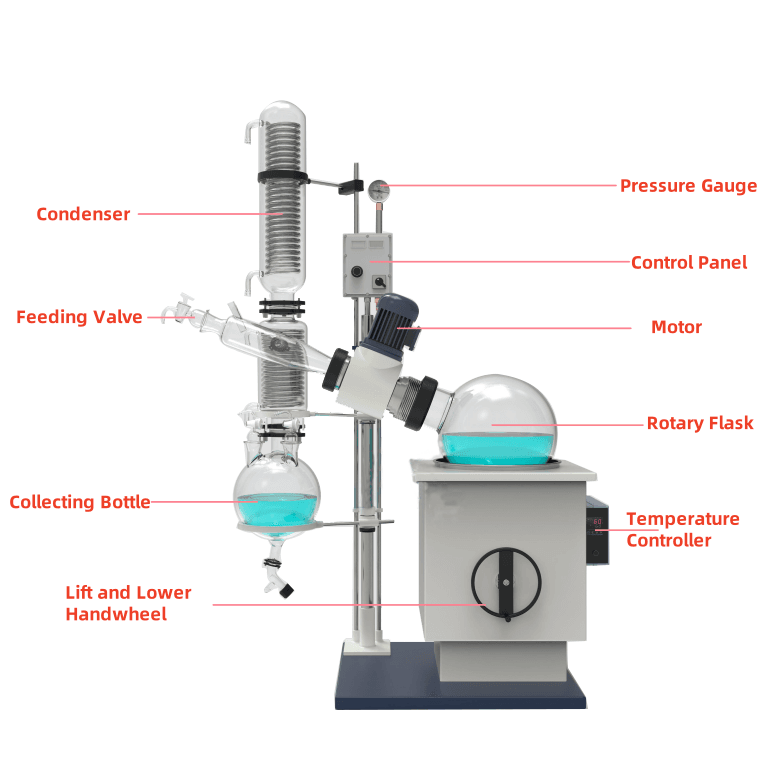

Large 10L rotating flask and 5L collection flask capacities for substantial sample processing

Powerful 3kW heating bath with 20L volume for consistent and rapid temperature control

Dual cooling area totaling 0.51㎡ enhances condensation efficiency

Rotating speed adjustable from 0 to 120 rpm for optimized evaporation rates

Manual lifting function for precise control of flask immersion depth

Vacuum degree of 0.098 MPa to reduce boiling points and protect heat-sensitive compounds

Optional explosion-proof motor, controller, and protective cover for enhanced safety

Technical Specifications of Rotovap Distillation

Rotating Flask Capacity: 10 L

Collection Flask Capacity: 5 L

Rotating Speed: 0–120 rpm

Cooling Area: 0.51 ㎡ (0.33 + 0.18)

Rotating Motor Power: 120 W

Heating Power: 3 kW

Bath Inner Volume: 20 L

Temperature Control Range: Ambient – 99℃ (Customizable)

Temperature Control Precision: ±1℃

Vacuum Degree: 0.098 MPa

Lifting Function: Manual

Power Supply: 220V / 50Hz (Customizable)

Optional: Anti-boiling & Explosion-proof Bath, Explosion-proof Motor, Controller, Protective Cover

Compatible Equipment for Enhanced Performance

Vacuum Pumps: To maintain stable vacuum pressure and improve evaporation efficiency.

Chillers or Cooling Circulators: To supply coolant for the condenser and optimize condensation.

Solvent Recovery Systems: For efficient collection and recycling of evaporated solvents, reducing waste.

Glassware Sets: Additional collection and receiving flasks to expand capacity and flexibility.

Digital Controllers: For automated temperature and vacuum regulation enhancing precision and safety.

These compatible devices maximize the rotovap distillation system’s efficiency and usability in various laboratory applications.

Emphasizing the Excellence of Our Rotovap Distillation System

Our rotovap distillation offers reliable, high-capacity solvent evaporation with precision temperature and vacuum control, ensuring optimal distillation outcomes for chemical, pharmaceutical, and research laboratories. The combination of powerful heating, effective cooling, and safety options like explosion-proof components makes it a trusted choice for demanding lab environments.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Cooling Solutions

Explore more advanced solutions in our rotary evaporator product category to find the perfect fit for your laboratory needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKRE-1002 | AKRE-2002 | AKRE-5002 |

|---|---|---|---|

| Rotating Flask Capacity (L) | 10 | 20 | 50 |

| Collection Flask Capacity (L) | 5 | 10 | 20 |

| Rotating Speed (rpm) | 0-120 | 0-120 | 0-120 |

| Cooling Area (㎡) | 0.51 (0.33 + 0.18) | 0.95 (0.46 + 0.49) | 1.44 (0.95 + 0.49) |

| Rotating Motor Power (W) | 120 | 120 | 120 |

| Heating Power (KW) | 3 | 3 | 8 |

| Bath Inner Volume (L) | 20 | 40 | 75 |

| Temperature Control Range | Ambient-99℃ (Customizable) | Ambient-99℃ (Customizable) | Ambient-99℃ (Customizable) |

| Temperature Control Precision | ±1℃ | ±1℃ | ±1℃ |

| Vacuum Degree (Mpa) | 0.098 | 0.098 | 0.098 |

| Lifting Function | Manual Lifting | Manual Lifting | Manual Lifting |

| Power Supply | 220V/50Hz (Customizable) | 220V/50Hz (Customizable) | 220V/50Hz (Customizable) |

| Anti-boiling & Explosion-proof Bath | Optional | Optional | Optional |

| Explosion-proof Motor | Optional | Optional | Optional |

| Explosion-proof Controller | Optional | Optional | Optional |

| Protective Cover | Optional | Optional | Optional |

introduce

Application Scenarios

The rotovap distillation system is a versatile tool widely used across academic, industrial, and pharmaceutical laboratories. Thanks to its precise temperature control, large flask capacity, and strong vacuum performance, it supports a broad range of applications involving solvent recovery, sample concentration, and purification.

Chemical Synthesis and Organic Reactions

In chemical and pharmaceutical labs, rotovap distillation is essential for removing solvents after synthesis. Its efficient vacuum and heating system allow for gentle evaporation of solvents without degrading sensitive compounds.Plant Extracts and Natural Product Research

Researchers frequently use rotovap distillation to concentrate and isolate natural extracts, such as essential oils, herbal extracts, and bioactive compounds. The 10L flask and customizable temperature range provide flexibility for various botanical materials.Pharmaceutical Formulation Development

In drug development, rotovap distillation is used for drying APIs (active pharmaceutical ingredients) and removing high-boiling-point solvents in formulation stages. Its precise control ensures reproducibility and safety in preclinical and clinical research.Food and Beverage Quality Control

Food scientists use rotovap distillation to analyze flavor compounds and remove unwanted solvents from extracts. It is particularly useful in aroma analysis, where high vacuum and low temperatures are needed to preserve volatile compounds.Cannabis and Hemp Processing

The rotovap distillation unit is widely adopted in cannabinoid purification workflows. It efficiently removes ethanol or other extraction solvents, preparing concentrates for further refinement or formulation.Educational and Training Laboratories

Universities and training institutions integrate rotovap distillation into lab curricula for teaching distillation principles, solvent handling, and evaporation techniques using safe and reliable equipment.

By covering multiple scientific and industrial needs, this rotovap distillation unit demonstrates its adaptability and performance across all application levels.

peculiarity

Stainless Steel + PTFE Composite Pot

This pot combines the durability of stainless steel with the non-stick properties of PTFE (Teflon), offering superior resistance to chemical reactions and easy maintenance. Ideal for various applications requiring a high-performance, non-reactive surface.

PTFE + Imported Fluororubber Combination

This combination utilizes PTFE (Teflon) and high-quality imported fluororubber to provide superior sealing performance. It offers excellent chemical resistance and durability, ensuring reliable operation under various conditions.

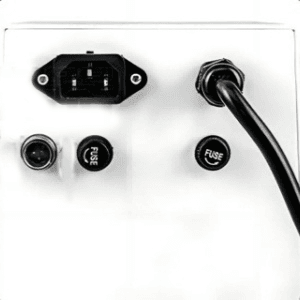

Power Plug and Fuse Switch

The device features a power plug for connection and a fuse switch for protection. The fuse switch ensures safety by protecting the equipment from electrical faults and overloads.

Vertical Double-Layer Serpentine Coil

This design features a vertical double-layer serpentine coil that ensures efficient heat exchange and high recovery rates. The compact and effective coil structure enhances overall performance and thermal efficiency.