Detailed Description

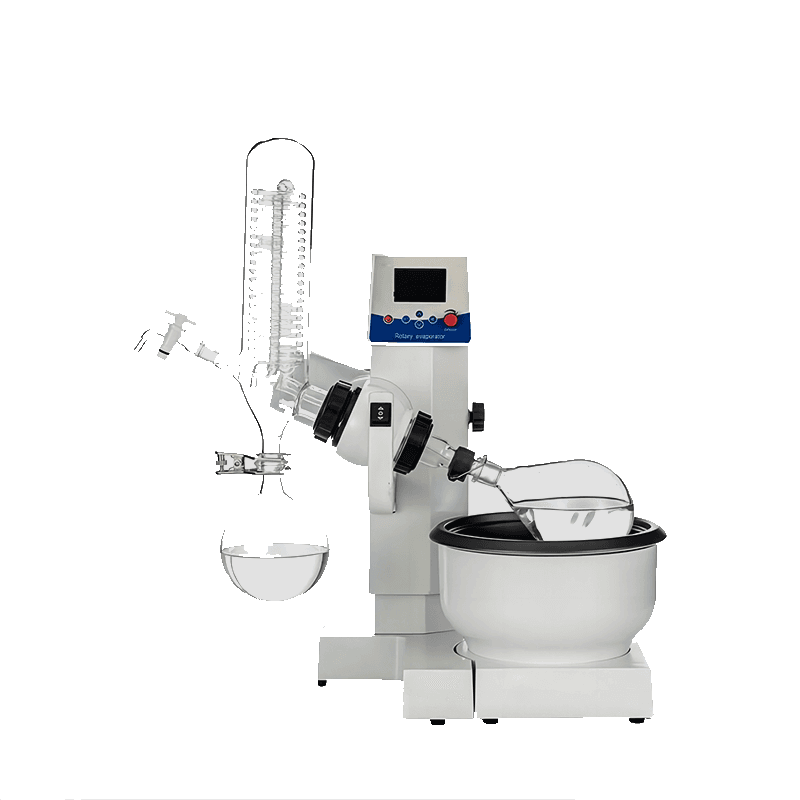

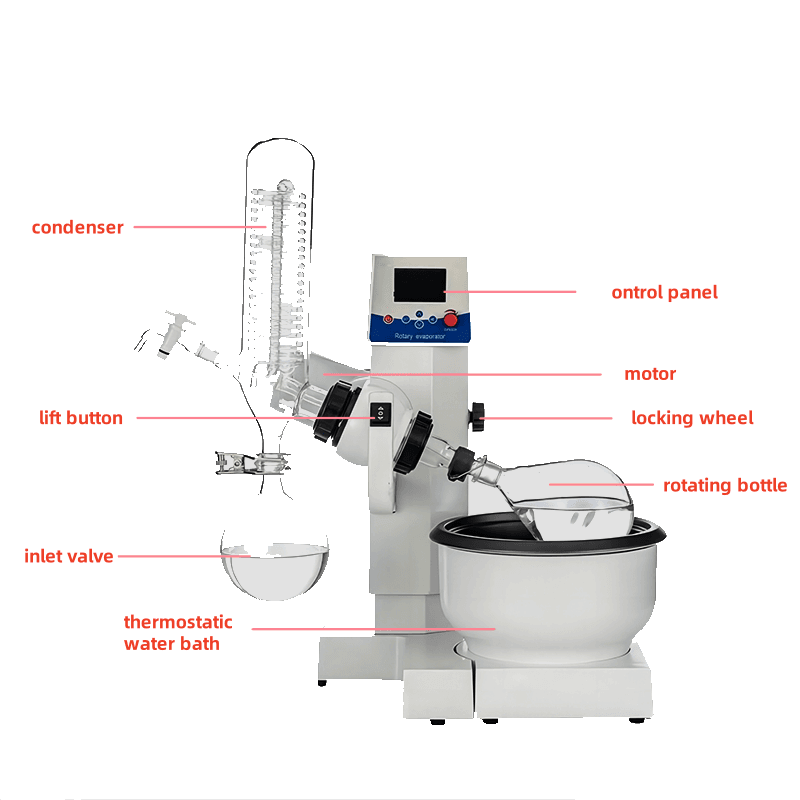

Key Features of the Electric Lift Laboratory Vacuum Evaporator

1L Rotary and Collection Flask: Standard joint glassware ensures tight connections and easy operation for solvent recovery

0.098 MPa Vacuum Performance: Enables rapid solvent removal at low temperatures, protecting heat-sensitive samples

Rotating Speed up to 200 rpm: Allows flexible control over evaporation speed for a variety of solvents

Electric Lifting Mechanism: 20 W motor provides smooth, hands-free adjustment of the flask position

Dual Heating Options: Water bath up to 99°C or oil bath up to 200°C for broader application compatibility

0.17 ㎡ Condenser Area: Maximizes condensation efficiency, reducing loss of valuable materials

Compact Design: Small footprint (630 × 400 × 690–810 mm) fits tight spaces while offering stable operation

Temperature Accuracy ±1°C: Ensures consistent process conditions for reliable evaporation results

Technical Specifications

Voltage: 220V / 50Hz

Total Power: 1260 W

Rotating Motor Power: 40 W

Lifting Motor Power: 20 W

Heating Power: 1200 W

Vacuum Degree: 0.098 MPa

Rotary Flask Capacity: 1L, Φ131mm / 24# standard joint

Collection Flask Capacity: 1L, Φ131mm / 35# spherical joint

Rotating Speed: 0–200 rpm

Temperature Range:

• Water Bath: RT–99°C

• Oil Bath: RT–200°C (optional)

Temperature Accuracy: ±1°C

Condenser Size: Φ85 × 430H mm, 35# spherical joint

Condenser Area: 0.17 ㎡

Pot Capacity: Ф235 × 145H mm, approx. 6.2L, 3.5 KG

Overall Dimensions: 630 × 400 × (690–810) mm

Filling Valve: 19# standard stopper valve, inlet Ø10mm

Machine Weight: 18.5 KG

Compatible Equipment for Enhanced Laboratory Evaporation

Vacuum Pump: Maintains 0.098 MPa vacuum level for optimal solvent evaporation and low boiling point operation

Low-Temperature Cooling Circulator: Enhances condenser efficiency, especially during long or continuous operations

Vacuum Controller: Provides precision vacuum regulation for reproducible results and sample safety

Drying Oven or Freeze Dryer: Complements downstream sample processing after evaporation

Glass Reactor: Useful for synthesis work that requires immediate post-reaction solvent removal using the evaporator

Why Choose This Electric Lift Laboratory Vacuum Evaporator

This Electric Lift Laboratory Vacuum Evaporator offers an ideal combination of precision, convenience, and safety. The electric lift system streamlines height adjustments, freeing lab technicians from manual operations. A dual-mode heating bath supports a wide range of solvents, while the 0.098 MPa vacuum degree ensures efficient solvent removal without compromising sample integrity. Compact and robust, this evaporator is well-suited for research labs, academic environments, and small-scale production requiring consistent evaporation performance.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Evaporation Systems

Discover additional models in our Electric Lift Laboratory Vacuum Evaporator category to find the ideal solution for your lab’s evaporation needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | RE-2000A | RE-2000B | RE-2000E |

|---|---|---|---|

| Voltage | 220V/50Hz | 220V/50Hz | 220V/50Hz |

| Total Power (W) | 1260 | 1260 | 1260 |

| Rotating Motor Power (W) | 40 | 40 | 40 |

| Lifting Motor Power (W) | 20 | 20 | 20 |

| Heating Power (W) | 1200 | 1200 | 1200 |

| Vacuum Degree (Mpa) | 0.098 | 0.098 | 0.098 |

| Rotary Flask Capacity | 1L, Φ131mm/24# standard joint | 1L, Φ131mm/24# standard joint | 1L, Φ131mm/24# standard joint |

| Collection Flask Capacity | 1L, Φ131mm/35# spherical joint | 1L, Φ131mm/35# spherical joint | 1L, Φ131mm/35# spherical joint |

| Rotating Speed (rpm) | 0-200 | 0-200 | 0-200 |

| Temperature Range | Water bath: RT-99°C; Oil bath: RT-200°C (optional) | Water bath: RT-99°C; Oil bath: RT-200°C (optional) | Water bath: RT-99°C; Oil bath: RT-200°C (optional) |

| Temperature Accuracy (±℃) | ±1°C | ±1°C | ±1°C |

| Condenser Size (mm) | Φ85x430H, 35# spherical joint | Φ85x430H, 35# spherical joint | Φ85x430H, 35# spherical joint |

| Condenser Area (㎡) | 0.17 | 0.17 | 0.17 |

| Pot Inner Dimensions & Capacity | Ф235x145H(mm), approx. 6.2L, 3.5KG | Ф235x145H(mm), approx. 6.2L, 3.5KG | Ф235x145H(mm), approx. 6.2L, 3.5KG |

| Overall Dimensions (mm) | 630x400x(690-810)mm (W x D x H) | 630x400x(690-810)mm (W x D x H) | 630x400x(690-810)mm (W x D x H) |

| Filling Valve | 19# Standard Stopper Valve, Inlet Nozzle (Hose Barb) Outer Diameter 10mm | 19# Standard Stopper Valve, Inlet Nozzle (Hose Barb) Outer Diameter 10mm | 19# Standard Stopper Valve, Inlet Nozzle (Hose Barb) Outer Diameter 10mm |

| Machine Weight (KG) | 20.5KG | 20.5KG | 18.5KG |

introduce

Application Scenarios

1. Organic Chemistry and Chemical Synthesis

This evaporator efficiently removes solvents from reaction mixtures during organic synthesis, offering precise temperature control (up to 99°C water bath or 200°C oil bath) and vacuum conditions (0.098 MPa). The 1L flask capacity and 0–200 rpm rotation speed adapt well to various sample sizes and solvent types.

2. Pharmaceutical Development and Drug Formulation

Ideal for concentrating active pharmaceutical ingredients (APIs) and solvent recycling in pharmaceutical labs. The electric lift design ensures safe and convenient operation, reducing manual handling risks during sensitive drug development processes.

3. Natural Product Extraction and Essential Oils

Widely used in phytochemical extraction to concentrate plant extracts and essential oils. The powerful 1200W heating and efficient condenser improve solvent recovery while preserving delicate compounds.

4. Food Science and Flavor Concentration

Supports evaporation and concentration of flavors, extracts, and food additives in food technology labs. The precise temperature accuracy (±1°C) ensures product quality and consistency.

5. Academic and Research Laboratories

This vacuum evaporator suits teaching and research labs for distillation and solvent removal experiments. Its easy-to-use electric lift and reliable vacuum system help students and researchers perform reproducible operations safely.

6. Environmental Testing and Sample Preparation

Used to concentrate environmental samples by removing solvents under controlled vacuum and temperature, aiding pollutant detection and analysis with high accuracy.

7. Cosmetic Industry Applications

Facilitates solvent removal during formulation and extraction of botanical ingredients in cosmetics R&D, enhancing production efficiency and product purity.

peculiarity

Stainless Steel + PTFE Composite Pot

This pot combines the durability of stainless steel with the non-stick properties of PTFE (Teflon), offering superior resistance to chemical reactions and easy maintenance. Ideal for various applications requiring a high-performance, non-reactive surface.

PTFE + Imported Fluororubber Combination

This combination utilizes PTFE (Teflon) and high-quality imported fluororubber to provide superior sealing performance. It offers excellent chemical resistance and durability, ensuring reliable operation under various conditions.

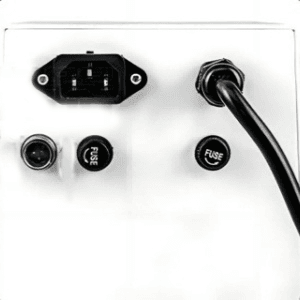

Power Plug and Fuse Switch

The device features a power plug for connection and a fuse switch for protection. The fuse switch ensures safety by protecting the equipment from electrical faults and overloads.

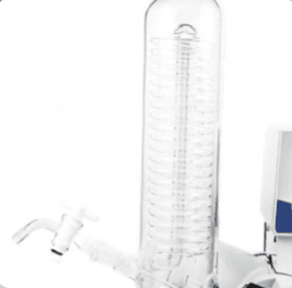

Vertical Double-Layer Serpentine Coil

This design features a vertical double-layer serpentine coil that ensures efficient heat exchange and high recovery rates. The compact and effective coil structure enhances overall performance and thermal efficiency.