Detailed Description

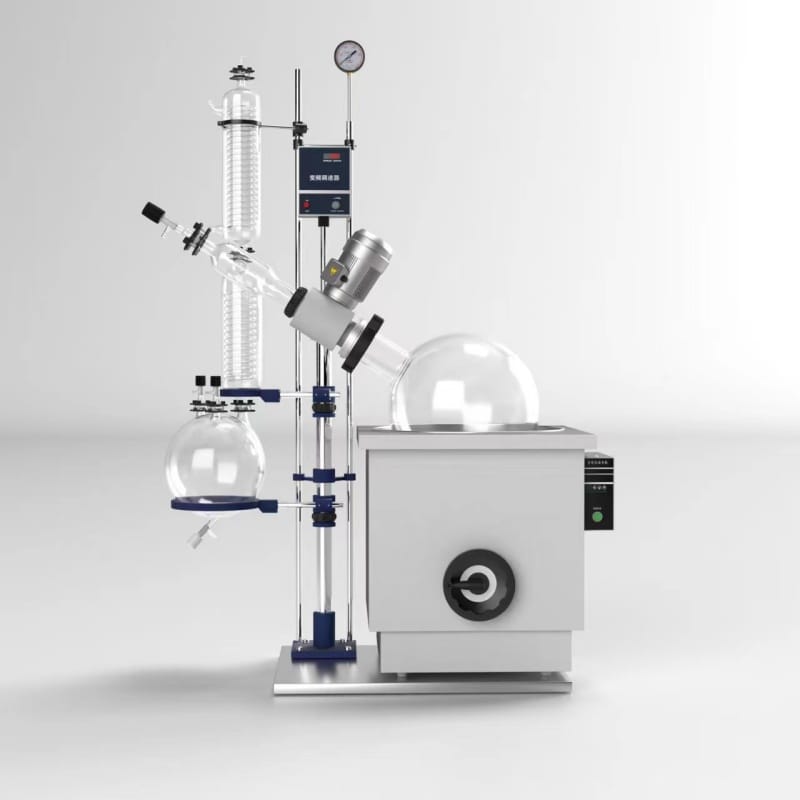

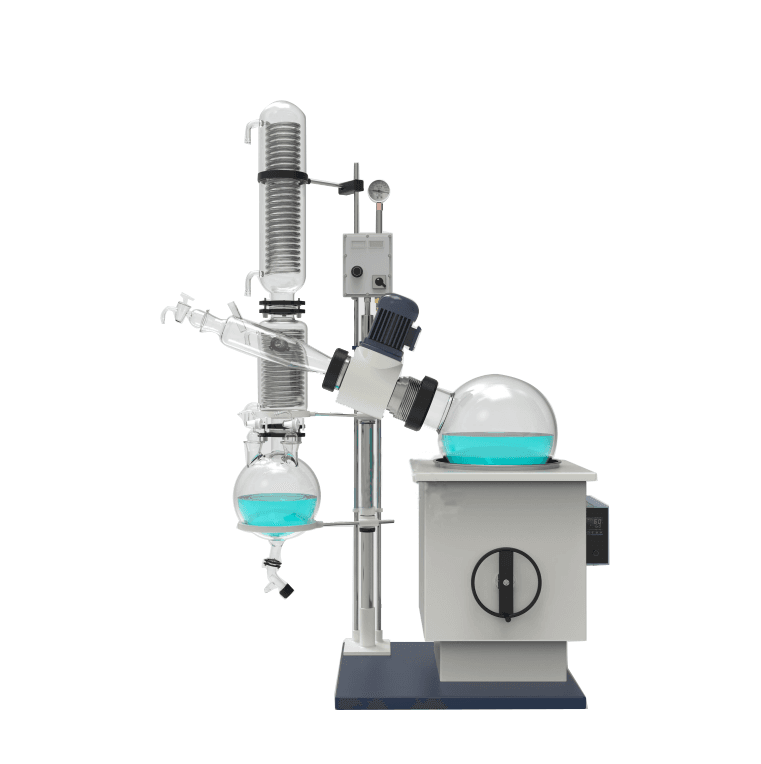

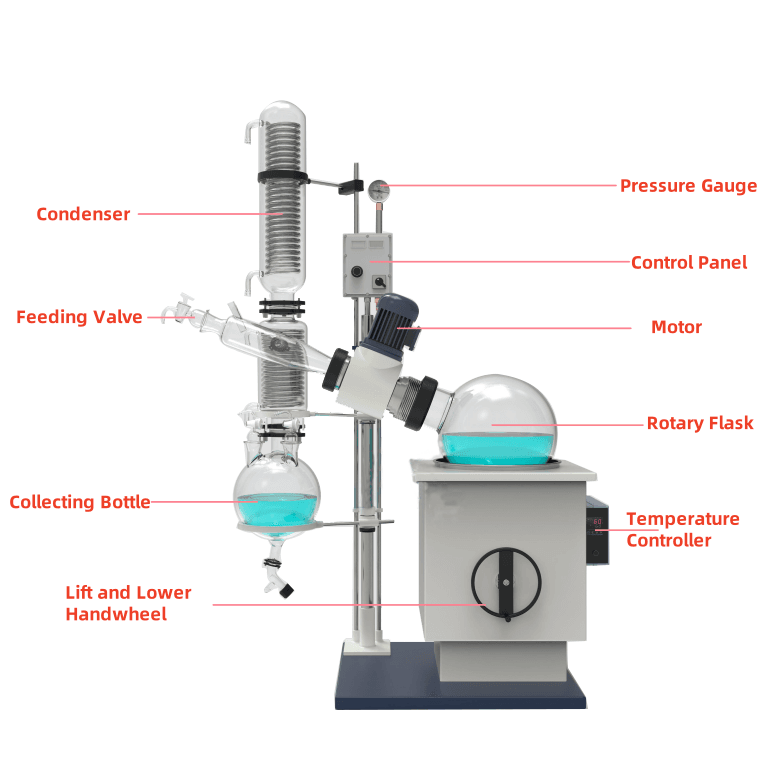

Key Features of the Manual Lift Rotary Evaporator

Large Capacity Operation: 50L rotating flask and 20L collection flask accommodate high-volume distillation needs.

Manual Lifting Mechanism: Stable and precise manual lift system supports controlled positioning and ease of operation.

Powerful Heating System: 8 kW heating capacity with a 75L water/oil bath for rapid temperature ramp-up.

Enhanced Cooling Efficiency: Dual condenser with a total cooling area of 1.44㎡ ensures optimal vapor condensation.

Reliable Vacuum Performance: Achieves up to 0.098 MPa vacuum for low-temperature evaporation.

Customizable Safety Options: Optional explosion-proof bath, motor, and controller for high-risk lab environments.

Technical Specifications

Rotating Flask Capacity: 50 L

Collection Flask Capacity: 20 L

Rotating Speed: 0–120 rpm

Cooling Area: 1.44 ㎡ (0.95 + 0.49)

Rotating Motor Power: 120 W

Heating Power: 8 kW

Bath Inner Volume: 75 L

Temperature Control Range: Ambient – 99℃ (Customizable)

Temperature Control Precision: ±1℃

Vacuum Degree: 0.098 MPa

Lifting Function: Manual Lifting

Power Supply: 220V / 50Hz (Customizable)

Optional Features: Anti-boiling bath, explosion-proof components, protective cover

Compatible Laboratory Equipment

Vacuum Pumps: Essential for maintaining 0.098 MPa vacuum level to support solvent evaporation.

Recirculating Chillers: Improve cooling performance and condenser efficiency for large-scale evaporation.

Vacuum Controllers: Ensure precise vacuum regulation to prevent bumping or boiling over.

Glass Receiving Flasks: Additional flasks for sample handling or switching during continuous runs.

Explosion-Proof Cabinets: Recommended when using flammable solvents with the optional explosion-proof system.

Designed for Demanding Manual Lift Rotary Evaporator Applications

This 50L Manual Lift Rotary Evaporator is the optimal choice for pilot plants, chemical laboratories, and pharmaceutical production environments requiring high-capacity solvent recovery. Its customizable design and optional safety enhancements make it suitable for a wide range of organic synthesis and separation processes. High durability and manual control offer balance between affordability and performance.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Manual Lift Rotary Evaporator Models

Discover more options in our Manual Lift Rotary Evaporator category for scalable evaporation systems tailored to your lab needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKRE-1002 | AKRE-2002 | AKRE-5002 |

|---|---|---|---|

| Rotating Flask Capacity (L) | 10 | 20 | 50 |

| Collection Flask Capacity (L) | 5 | 10 | 20 |

| Rotating Speed (rpm) | 0-120 | 0-120 | 0-120 |

| Cooling Area (㎡) | 0.51 (0.33 + 0.18) | 0.95 (0.46 + 0.49) | 1.44 (0.95 + 0.49) |

| Rotating Motor Power (W) | 120 | 120 | 120 |

| Heating Power (KW) | 3 | 3 | 8 |

| Bath Inner Volume (L) | 20 | 40 | 75 |

| Temperature Control Range | Ambient-99℃ (Customizable) | Ambient-99℃ (Customizable) | Ambient-99℃ (Customizable) |

| Temperature Control Precision | ±1℃ | ±1℃ | ±1℃ |

| Vacuum Degree (Mpa) | 0.098 | 0.098 | 0.098 |

| Lifting Function | Manual Lifting | Manual Lifting | Manual Lifting |

| Power Supply | 220V/50Hz (Customizable) | 220V/50Hz (Customizable) | 220V/50Hz (Customizable) |

| Anti-boiling & Explosion-proof Bath | Optional | Optional | Optional |

| Explosion-proof Motor | Optional | Optional | Optional |

| Explosion-proof Controller | Optional | Optional | Optional |

| Protective Cover | Optional | Optional | Optional |

introduce

Application Scenarios

Chemical Laboratories: The Manual Lift Rotary Evaporator is essential in chemical labs for large-scale solvent evaporation, enabling efficient concentration and recovery of solvents in synthesis and analysis processes. It supports various organic and inorganic chemical reactions by removing volatile solvents under vacuum and controlled temperature.

Pharmaceutical Research: This rotovap is widely used in pharmaceutical development for concentrating active pharmaceutical ingredients (API). It allows precise temperature control and vacuum settings to ensure compound stability during solvent removal, which is critical for drug formulation and purity testing.

Food and Beverage Industry: The equipment is ideal for extracting and purifying flavors, essential oils, and other volatile compounds in food and beverage processing. Its large capacity supports scale-up production, helping maintain the integrity and aroma of sensitive ingredients through gentle evaporation.

Environmental Laboratories: Environmental scientists use the rotary evaporator to concentrate samples such as water or soil extracts for pollutant analysis. The precise vacuum and temperature controls enable safe removal of solvents without degrading target analytes, ensuring accurate environmental monitoring.

Material Science Research: In material science and chemical engineering, the rotovap is utilized to purify and prepare chemical compounds, polymers, and nanomaterials. Its adjustable rotation speed and heating power provide versatile evaporation conditions, essential for experimental reproducibility.

Academic and Industrial Research: This rotary evaporator serves both academic research labs and industrial R&D facilities, where reproducible solvent removal and sample concentration are vital. The manual lift function provides ease of operation and flexibility for handling large volume batches safely.

peculiarity

Stainless Steel + PTFE Composite Pot

This pot combines the durability of stainless steel with the non-stick properties of PTFE (Teflon), offering superior resistance to chemical reactions and easy maintenance. Ideal for various applications requiring a high-performance, non-reactive surface.

PTFE + Imported Fluororubber Combination

This combination utilizes PTFE (Teflon) and high-quality imported fluororubber to provide superior sealing performance. It offers excellent chemical resistance and durability, ensuring reliable operation under various conditions.

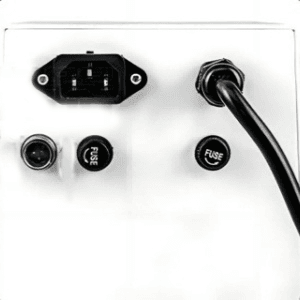

Power Plug and Fuse Switch

The device features a power plug for connection and a fuse switch for protection. The fuse switch ensures safety by protecting the equipment from electrical faults and overloads.

Vertical Double-Layer Serpentine Coil

This design features a vertical double-layer serpentine coil that ensures efficient heat exchange and high recovery rates. The compact and effective coil structure enhances overall performance and thermal efficiency.