Detailed Description

Key Features of the Lifting and Rotating Reactor

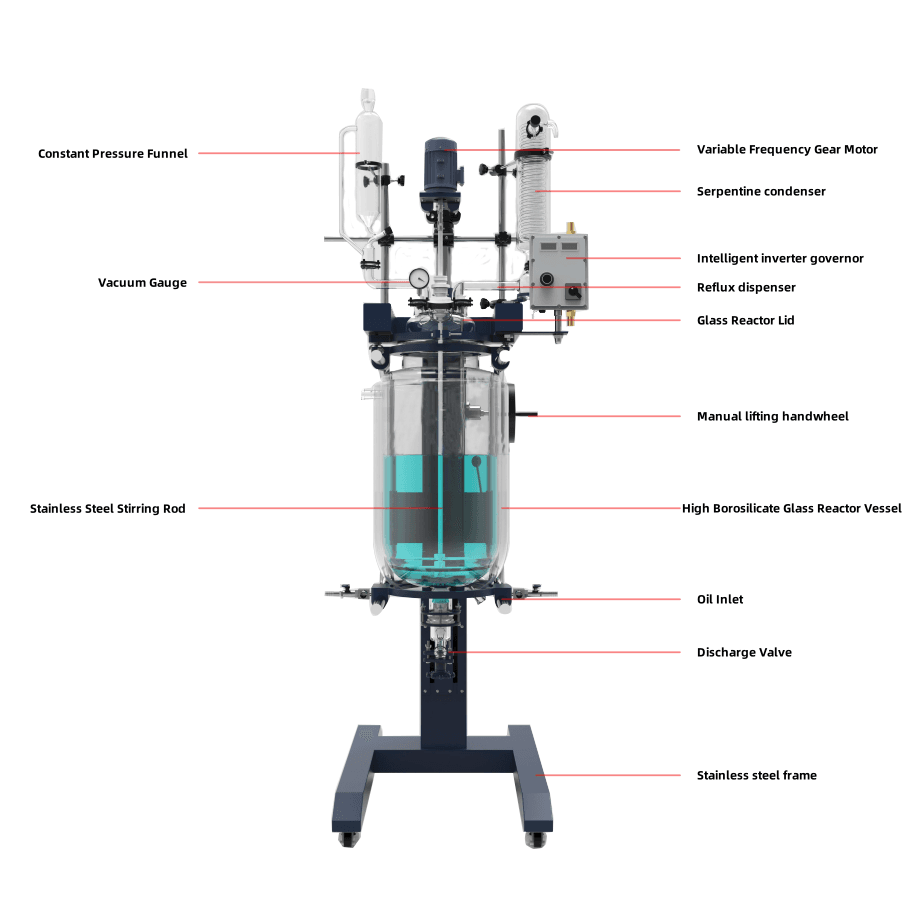

6L jacket volume ensures stable and efficient temperature control throughout the process

Stirring shaft made from stainless steel coated with fluorine materials for exceptional chemical resistance and durability

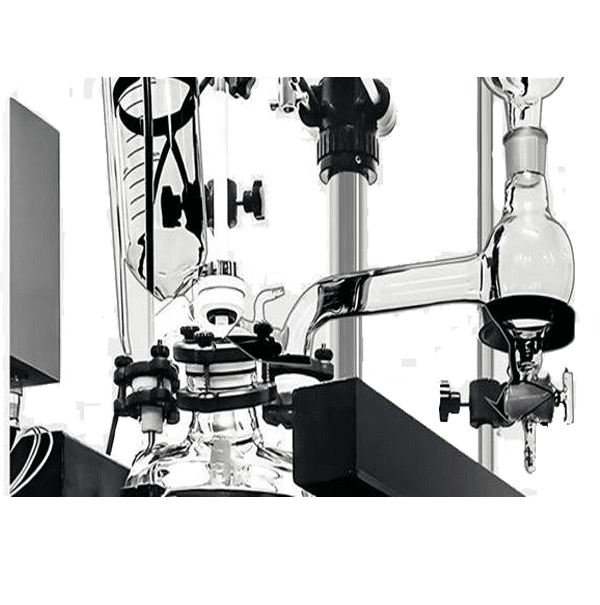

Equipped with 6 customizable ports for flexible connection of additional laboratory apparatus

Digital frequency control offers precise speed adjustment from 0 to 450 RPM

Mixing power of 90W guarantees effective stirring performance for various chemical reactions

Optional explosion-proof feature enhances safety in hazardous environments

Optional automatic control provides improved operational efficiency and convenience

Optional insulation layer maintains temperature stability and reduces energy consumption

Technical Specifications

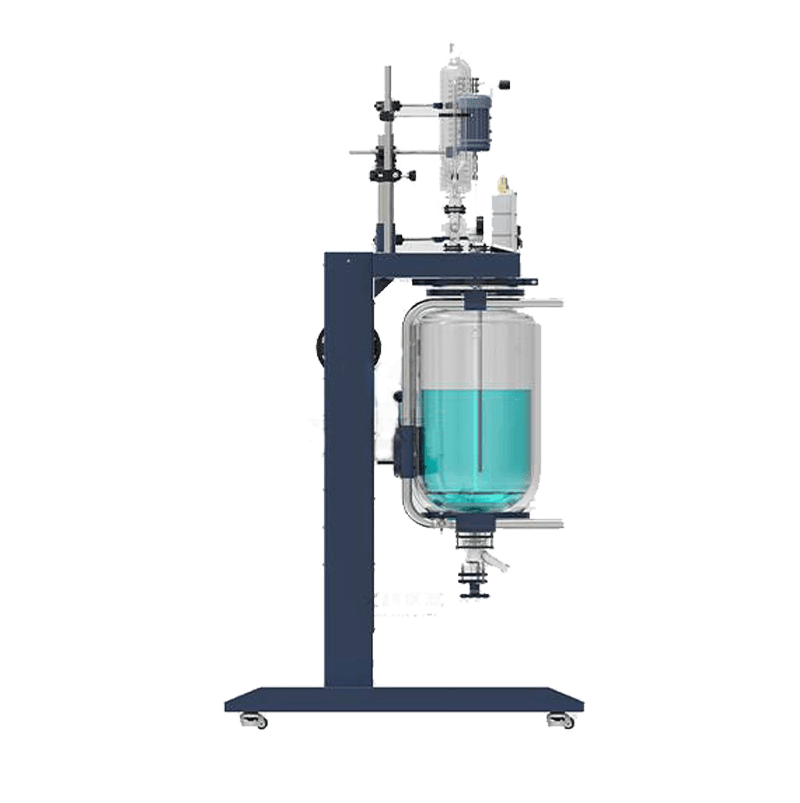

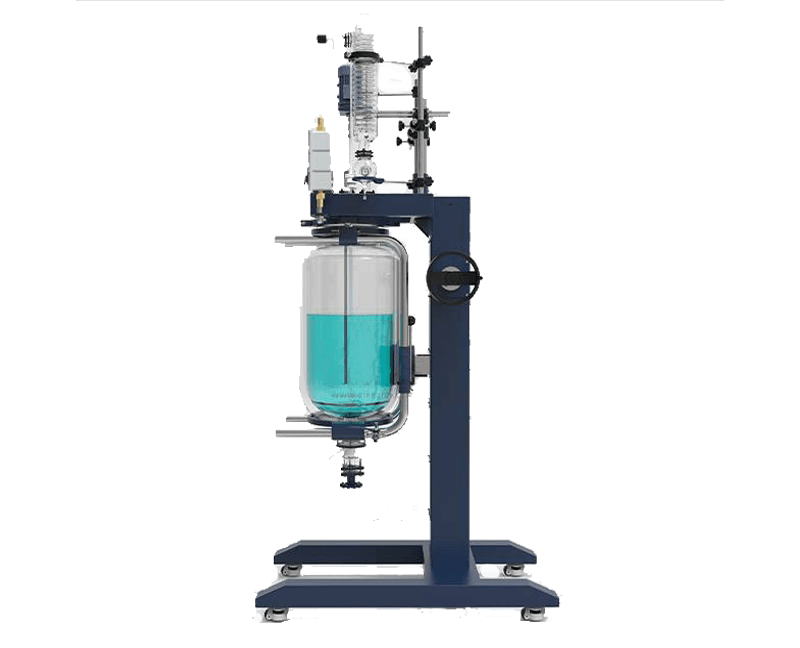

Volume: 20L

Jacket Volume: 6L

Body Material: Borosilicate Glass GG-17

Temperature Range: -80°C to 280°C

Temperature Resistance: -120°C to 300°C

Body Angle: 150°

Vacuum Degree: 0.098 MPA

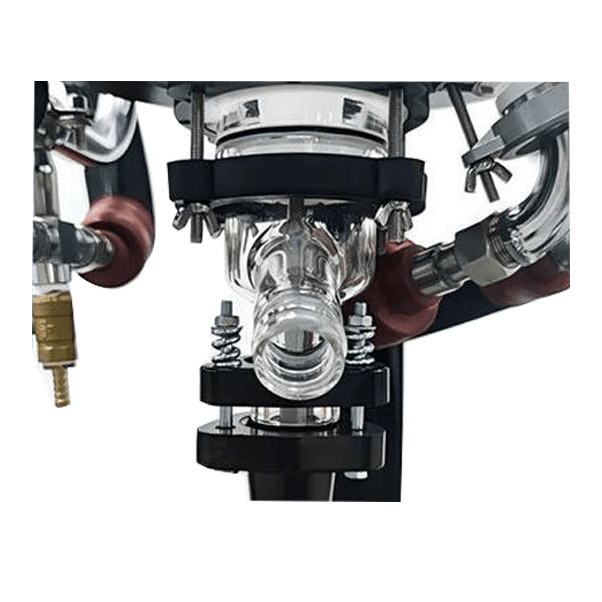

Mixing Shaft Connection: Universal Joint

Mixing Power: 90W

Speed Adjustment Mode: Digital Frequency Control

Rotation Speed: 0–450 RPM

Stirring Shaft Material: Stainless Steel Coated with Fluorine Materials

Number of Joints: 6 Ports (Customizable)

Voltage/Frequency: 220V / 50Hz

Explosion-Proof Option: Optional

Automatic Control Option: Optional

Insulation Layer Option: Optional

Compatible Equipment Recommendations

Heating Circulators: To provide accurate temperature control compatible with the 6L jacket volume

Vacuum Pumps: To maintain the vacuum degree of 0.098 MPA necessary for certain reactions in the lifting and rotating reactor

Magnetic or Overhead Stirrers: To complement the stirring shaft and improve mixing versatility

Explosion-Proof Accessories: Recommended for handling sensitive or volatile chemicals safely

Digital Control Systems: To enable optional automatic control features for enhanced process automation

Highlighted Advantages of the Lifting and Rotating Reactor

The lifting and rotating reactor combines durable borosilicate glass construction with a functional lifting design that simplifies cleaning and operation. Its broad temperature range, precise vacuum control, and customizable ports deliver flexibility for complex laboratory reactions. Advanced digital frequency speed control and optional explosion-proof and automation features ensure safety and reliability, making this lifting and rotating reactor a top choice for demanding chemical processes.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Explore More Cooling Solutions

Explore more models in our lifting and rotating reactor category for comprehensive solutions tailored to your laboratory needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Model | AKSF-10L | AKSF-20L | AKSF-30L | AKSF-50L |

|---|---|---|---|---|

| Volume (L) | 10L | 20L | 30L | 50L |

| Jacket Volume (L) | 3L | 6L | 10L | 16L |

| Body Material | Borosilicate Glass GG-17 | |||

| Temperature Range | -80°C ~ 280°C | |||

| Body Angle | 150° | |||

| Vacuum Degree | 0.098 MPA | |||

| Mixing Shaft Connection | Universal Joint | |||

| Mixing Power | 90W | 90W | 120W | 120W |

| Speed Adjustment Mode | Digital Frequency Control | |||

| Number of Joints | 6 Ports (Customizable) | |||

| Stirring Shaft Material | Stainless Steel Coated with Four Fluorine Materials | |||

| Rotation Speed (RPM) | 0–450 RPM | |||

| Temperature Resistance | Low Temp: -120°C to High Temp: 300°C | |||

| Speed Control | Frequency Control | |||

| Voltage/Frequency | 220V/50Hz | |||

| Anti-Explosion | Optional | |||

| Automatic Control | Optional | |||

| Insulation Layer | Optional | |||

introduce

Application Scenarios

Chemical Synthesis: Ideal for complex chemical reactions requiring precise temperature and stirring control, supporting both low and high-temperature processes within -80°C to 280°C.

Pharmaceutical Research: Perfect for developing new drugs and formulations with its accurate vacuum degree of 0.098 MPA and customizable 6 ports for adding reagents or sensors.

Material Science: Suitable for polymerization and material modification reactions that demand controlled stirring speeds from 0 to 450 RPM and stable mixing power of 90W.

Food and Beverage Industry: Used in the development of flavors, extracts, and emulsions where gentle yet consistent mixing is essential.

Environmental Testing: Supports safe reactions in laboratories focusing on environmental samples, with optional explosion-proof features for handling volatile substances.

Academic and Industrial Laboratories: Facilitates teaching and research applications needing versatile, reliable, and easily operable reactors with lifting and rotating functions for enhanced accessibility.

peculiarity

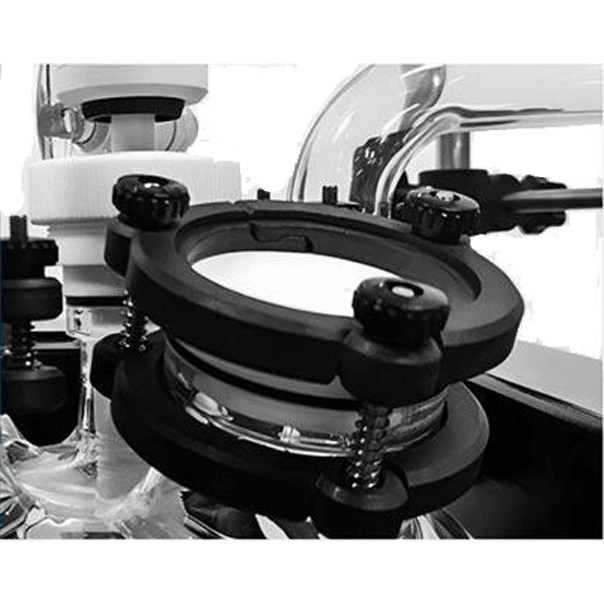

The reactor lid is made of PTFE material.

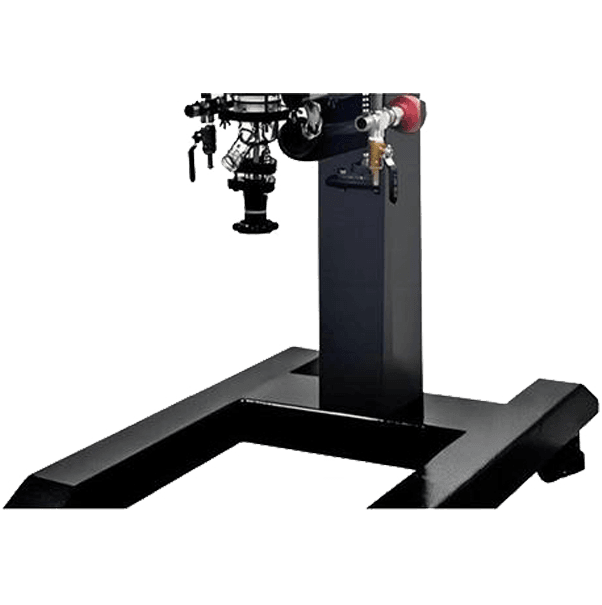

The main bracket is made of square steel anti-corrosion spraying + aluminum alloy + stainless steel

The lid and the part above the lid can be lifted electrically

The discharge valve is made of glass and PTFE, designed for side discharge with no liquid retention.

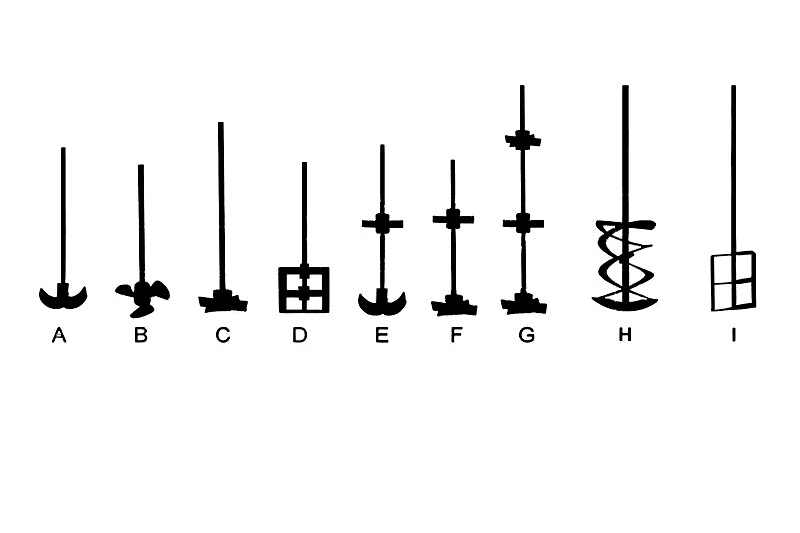

According to the different properties and viscosities of materials, a variety of stirring paddles are available for your selection. The standard configuration includes ABCD types of stirring rods, with the A-type paddle recommended for the bottle neck, and custom-made EF and G types of stirring rods are available as well