Detailed Description

Product Overview

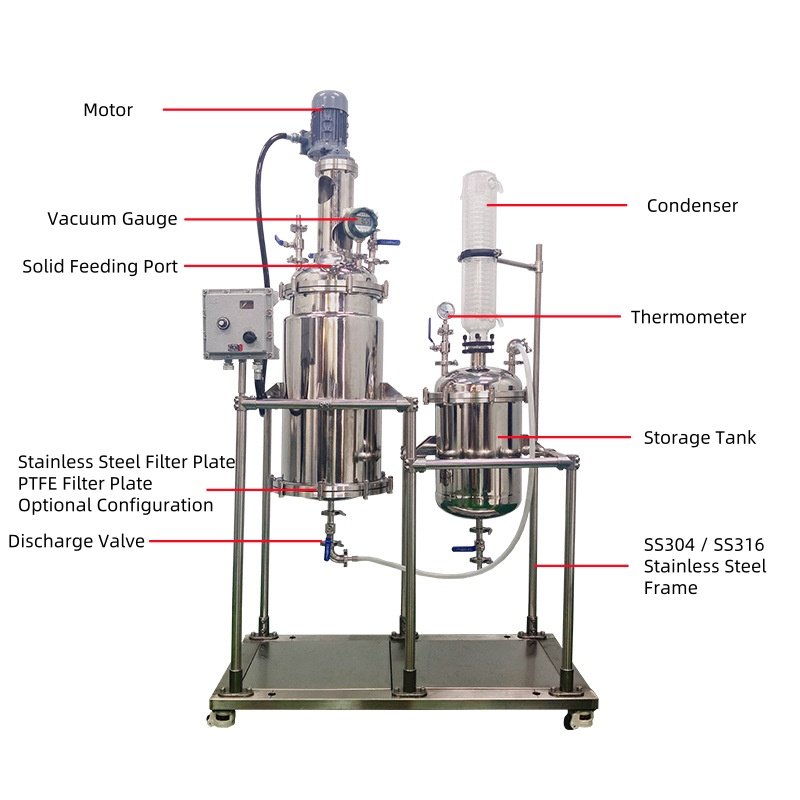

Constructed with SUS316L stainless steel contact parts and SUS304 non-contact components, the reactor provides superior corrosion resistance, mechanical strength, and long-term operational reliability. Its mechanical seal and variable frequency stirring system ensure stable operation under vacuum or pressure, while the double-layer jacketed design supports heating and cooling via thermal oil, water, or glycol.

This system is widely used as a laboratory crystallization reactor, a pilot scale crystallization filtration system, or a vacuum crystallization filtration reactor, providing flexible solutions for diverse crystallization applications. It is especially suited as a pharmaceutical crystallization reactor where purity, control, and reproducibility are critical.

Key Features of the Crystallization Filtration Reactor

Working volumes from 10L to 50L, adaptable for lab research and pilot production

Double-layer jacketed stainless steel vessel for precise temperature control during crystallization

Integrated SUS316L filtration plate (10 μm pore size) for efficient in-situ solid–liquid separation

Mechanical seal system ensures stable, leak-free operation

Variable frequency stirring system with adjustable speed ranges:

80–460 rpm (3:1 gearbox)

80–350 rpm (4:1 gearbox)

Comprehensive reactor lid ports for temperature measurement, solid and liquid feeding, gas balance, sight glass, and gas inlet

Wide operating conditions: –0.1 to 0.1 MPa, –20°C to 200°C

Durable SUS316L/SUS304 construction, ensuring chemical compatibility and long-term use

Technical Specifications – 10L–50L Crystallization Filtration Reactor

Capacity: 10L / 20L / 30L / 50L

Contact Material: SUS316L Stainless Steel

Non-Contact Material: SUS304 Stainless Steel

Seal Type: Mechanical Seal

Motor Power: 200W (10L/20L), 370W (30L), 750W (50L)

Speed Range: 80–460 rpm (3:1 Gearbox, 10–30L), 80–350 rpm (4:1 Gearbox, 50L)

Filter Plate: SUS316L, 10 μm Pore Size

Liquid Outlet: TC50.5 × DN38

Pressure Range: –0.1 ~ 0.1 MPa

Temperature Range: –20°C ~ 200°C

Power Supply: AC 220V / 1 Phase

Reactor Lid Port Configuration

Temperature Port: TC50.5 DN20

Solid Feeding Port: DN50 (10L/20L), DN80 (30L/50L)

Liquid Feeding Port: TC50.5 DN20 with Ball Valve

Gas Balance Port: TC50.5 DN20 with Ball Valve

Sight Glass: DN50

Gas Inlet: TC50.5 DN20 with Ball Valve

Compatible Equipment for Crystallization Filtration Processes

High-Temperature Circulating Oil Bath – precise heating for stable crystallization

Vacuum Pump – enhances filtration efficiency under reduced pressure

Chiller or Cooling Circulator – maintains controlled low-temperature conditions

Scrubber System – safely manages exhaust gases

Glass or Stainless Steel Condenser – supports reflux and condensation

Applications of the Crystallization Filtration Reactor

Pharmaceutical crystallization and filtration

Fine chemical and intermediate synthesis

Material science and advanced material processing

Laboratory-scale research and pilot plant production

Solid–liquid separation under controlled temperature and vacuum conditions

Explore Related Crystallization Reactor Systems

Jacketed glass reactors offer excellent visibility, chemical resistance, and precise temperature control, making them ideal for processes that require careful monitoring and controlled crystallization.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Item | ERL-10L | ERL-20L | ERL-30L | ERL-50L |

|---|---|---|---|---|

| Working Volume | 10 L | 20 L | 30 L | 50 L |

| Material | Contact part: SUS316L Non-contact part: S304 | |||

| Sealing Type | Mechanical Seal | |||

| Agitation Power | 200 W Variable frequency speed control adjustable 80–460 rpm (with 3:1 gearbox ratio) | 370 W Variable frequency speed control adjustable 80–460 rpm (with 3:1 gearbox ratio) | 750 W Variable frequency speed control adjustable 80–350 rpm (with 4:1 gearbox ratio) | |

| Reactor Lid Ports |

Temperature port TC50.5DN20 Solid feeding port DN50 Liquid feeding port TC50.5DN20 with 1 ball valve Gas balance port TC50.5DN20 with 1 ball valve Sight glass DN50 Gas inlet TC50.5DN20 with 1 ball valve | |||

| Filter Plate Material | SUS316L | |||

| Filter Plate Pore Size | 10 μm | |||

| Liquid Outlet | TC50.5*DN38 | |||

| Operating Pressure | –0.1 ~ 0.1 MPa | |||

| Power Supply | 220V / 1 Phase | |||

introduce

Application Scenarios

Pharmaceutical Industry

The stainless steel filtration reactor is widely used in pharmaceutical production for crystallization, solid-liquid separation, and vacuum filtration. Its corrosion-resistant SUS316L contact parts ensure compliance with GMP standards and provide safe handling of sensitive compounds.Fine Chemicals Manufacturing

In the fine chemical industry, the stainless steel filtration reactor supports reactions such as polymerization, neutralization, and catalytic processes. Its filtration function simplifies downstream processing by reducing extra transfer steps.Biotechnology and Fermentation

The reactor is suitable for biomass processing, enzyme reactions, and fermentation experiments where both agitation and solid separation are required. The integrated filtration plate enables efficient collection of microbial cells or biomass.Petrochemical Applications

The stainless steel filtration reactor can be applied in petrochemical labs and pilot plants for testing additives, refining intermediates, and separating solid by-products under controlled pressure and temperature.Material Science and Research

In laboratories focusing on nanomaterials, catalysts, or advanced polymers, the reactor enables precise reaction control and easy recovery of solid products. The 10 μm filter plate supports uniform particle separation and collection.

peculiarity

Compatible Equipment

High and Low Temperature Integrated Machine – Provides precise heating and cooling, ensuring stable reaction conditions.

Stainless Steel Solid Phase Reactor – Works in combination for solid–liquid separation and advanced synthesis processes.

Low Temperature Cooling Circulator – Maintains consistent low-temperature environments for sensitive reactions.

Recirculating Water Vacuum Pump – Ensures efficient vacuum conditions for filtration and evaporation.