Product specifications

| Parameter | 50ml | 100ml | 250ml | 500ml |

|---|---|---|---|---|

| Reactor Volume | 50ml | 100ml | 250ml | 500ml |

| Pressure Range | Up to 22MPa | |||

| Temperature Range | 0°C to 350°C | |||

| Stirring Speed | 0-1800 rpm (adjustable) | |||

| Heating Power | 0.6 kW | 0.6 kW | 0.6 kW | 1.5 kW |

| Heating Method | Modular electric heating | |||

| Stirring Method | Bottom magnetic stirring | |||

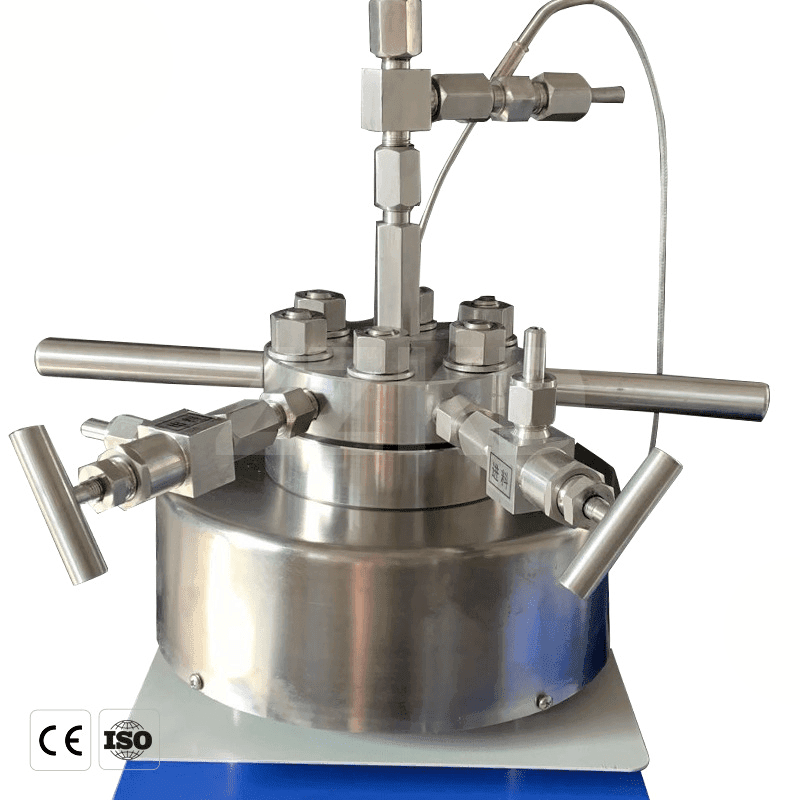

| Material | Stainless Steel 304 & 316 | |||

| Display | Digital screen display | |||

| Connection Type | Flange connection | |||

introduce

Product features:

- Precise Control: Provides high-precision control of pressure, temperature, and stirring speed, making it suitable for various experimental applications such as chemical synthesis and hydrogenation reactions.

- Efficient Mixing: Equipped with a magnetic stirring system to ensure uniform mixing even under high-pressure conditions, improving reaction efficiency.

- Wide Range of Applications: Ideal for catalytic reactions, pharmaceutical research, material testing, and other fields, offering high flexibility in reactions.

- Safety Assurance: Designed to meet high-pressure operation standards, ensuring stable performance under extreme temperature and pressure conditions.

- Modular Heating System: Allows selection of appropriate heating power based on the reactor volume (50ml to 500ml), ensuring precise temperature control during reactions.

peculiarity

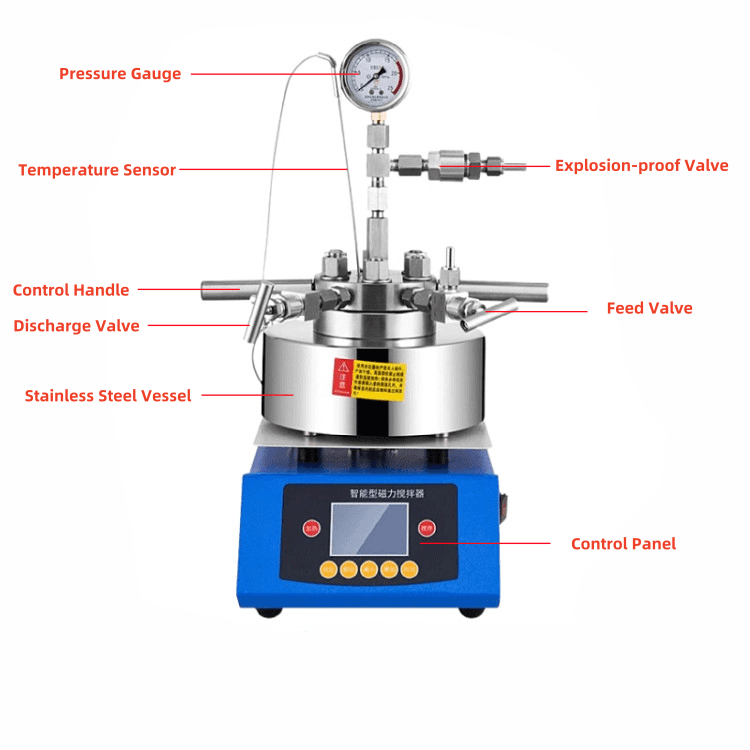

Explosion-proof valves

Stainless steel explosion-proof valve, safe and reliable

Pressure Gauge

Real-time Monitoring of Reaction Pressure in the Vessel

Stainless Steel Reactor Lid

Equipped with Inlet Valve, Sampling Valve, Exhaust Valve, Pressure Gauge, and Temperature Probe

Control Panel

Precise control with digital display on the screen, Adjustable temperature and speed.