Detailed Description

Key Features

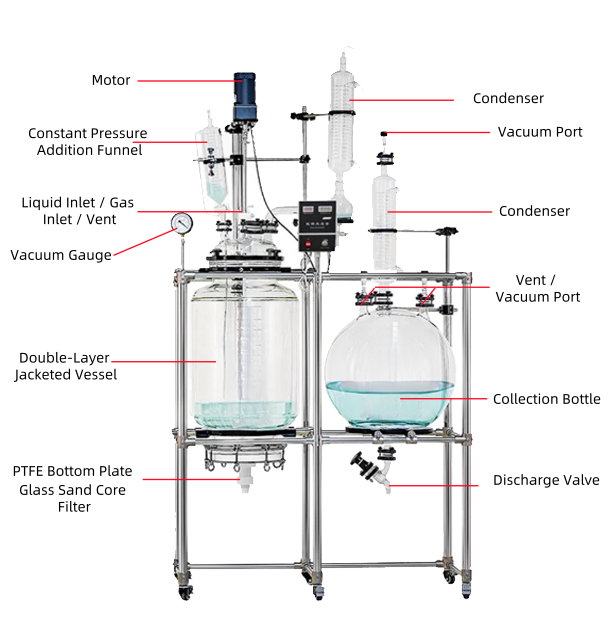

The Jacketed Glass Crystallization Filtration Reactor features a double-layer jacketed glass design for uniform heating or cooling during crystallization and filtration processes. It includes a removable PTFE bottom filter plate compatible with sand cores, filter cloth, or mesh for flexible filtration. Multiple ports (5–6) support stirring, constant pressure addition, temperature monitoring, and optional reflux.

A high-performance 120W low-speed torque motor with inverter controller provides stable stirring up to 600 rpm. Solid feeding ports with PTFE covers and spherical or coil condenser options allow customization for different laboratory reaction setups.

Technical Specifications

Material Capacity: 2L / 5L / 10L / 20L / 50L

Jacket Capacity: 1.2L / 3L / 3L / 6L / 16L

Number of Ports: 5–6 (Stirring / Spare / Constant Pressure Addition / Temperature / Reflux)

Motor Power: 120W Low-Speed Torque Motor (Gear Ratio 1:3)

Speed Range: 0–600 rpm, digital display for speed and temperature

Mechanical Seal: 50 Flange PTFE + SiC + Ceramic High-Seal Assembly

Feeding Valve: 24# or 34# Standard Ground Joint

Temperature Tube: 19# Standard Ground Joint or 43# Flange Port

Constant Pressure Addition Funnel: 250 ml – 2000 ml

Reflux Head: 200 ml – 1000 ml Ball Joint

Solid Feeding Port: 80 Flange Port with 60 mm inner diameter PTFE cover

Condenser Type: Spherical or Coil

Stirring Shaft: 316L Stainless Steel with PTFE Sleeve, multiple designs available

Power Supply: 220V / 50Hz

Compatible Equipment

Vacuum Pump – improves filtration efficiency under reduced pressure

Circulating Water or Oil Bath – provides precise jacketed temperature control

Magnetic Stirrer or Overhead Stirrer – ensures uniform mixing during reactions

Gas Supply System – supports gas-liquid reactions and inert atmosphere operations

Filter Cloth and Mesh Sets – allow quick adaptation to different filtration requirements

Typical Applications

Pharmaceutical crystallization and API purification

Chemical synthesis and intermediate filtration

Solid-liquid separation after reactions

Vacuum filtration under controlled temperature

Fine chemical, biological, and food laboratory research

Highlighted Advantages

The Jacketed Glass Crystallization Filtration Reactor offers high chemical resistance, excellent visibility, and precise temperature control in a single system. By integrating reaction, crystallization, and filtration functions, it eliminates material transfer steps, reduces product loss, and improves laboratory efficiency. Its modular design and multiple configuration options make it ideal for both laboratory and pilot-scale applications requiring efficient crystallization and filtration processes.

More Options

Explore more configurations and capacities in our Jacketed Stainless Steel Crystallization Filtration Reactor page to find the ideal solution for your laboratory crystallization, vacuum filtration, and solid-liquid separation processes.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | ERL-2L | ERL-5L | ERL-10L | ERL-20L | ERL-50L |

|---|---|---|---|---|---|

| Material Capacity | 2L | 5L | 10L | 20L | 50L |

| Jacket Capacity | 1.2L | 3L | 3L | 6L | 16L |

| Number of Ports | 5 Ports (Stirring Port / Spare Port / Constant Pressure Addition Funnel / Temperature Port / Reflux Condenser Port) | 6 Ports (Stirring Port / Spare Port / Constant Pressure Addition Funnel / Temperature Port / Reflux Condenser Port) | |||

| Power | 120W Low-Speed Torque Motor (Gear Ratio 1:3) | ||||

| Controller | Inverter, Digital Display Speed & Temperature, Adjustable Speed Knob | ||||

| Speed | 0–600 rpm | ||||

| Mechanical Seal | 50 Flange PTFE + SiC + Ceramic High-Seal Assembly | ||||

| Feeding Valve | 24# Standard Ground Joint | 34# Standard Ground Joint | |||

| Temperature Tube | 19# Standard Ground Joint | 43# Flange Port | |||

| Constant Pressure Addition Funnel | 24# Standard Ground Joint, 250ml | 24# Standard Ground Joint, 500ml | 34# Standard Ground Joint, 1000ml | 34# Standard Ground Joint, 2000ml | |

| Reflux Head | 35# Ball Joint, 200ml | 35# Ball Joint, 500ml | 50# Ball Joint, 1000ml | ||

| Solid Feeding Port | / | / | 80 Flange Port, 60 mm Inner Diameter, with Matching PTFE Cover | ||

| Condenser | 24# Standard Ground Joint, Spherical Condenser | 29# Standard Ground Joint, Coil Condenser | 40# Standard Ground Joint, Coil Condenser | ||

| Stirring Shaft | 316L Stainless Steel Sleeve with PTFE Tube, Options: Anchor, Three-Blade, Four-Blade | ||||

| Bottom PTFE Filter Plate | Removable and replaceable; compatible with sand core, filter cloth, or mesh | ||||

| Power Supply (V/Hz) | 220/50 | ||||

introduce

Application Scenarios

The Filtration Reactor is widely used in pharmaceutical, chemical, biological, food, and environmental laboratories. It is ideal for:

Mixing and homogenizing chemical or biological materials with precise temperature control

Stirring, filtration, and vacuum filtration for high-efficiency separation of solids and liquids

Cooling and crystallization processes in pharmaceutical and chemical production

Gas-liquid reactions using bottom gas injection for accelerated reaction rates

Laboratory experiments requiring reflux, condensation, and controlled addition of reagents

The Filtration Reactor ensures reproducible results and efficient processing, making it a versatile choice for research and production applications.

peculiarity

Compatible Equipment

- High-Low Temperature Integrated Unit – provides both heating and cooling for precise reaction control

- Low-Temperature Circulating Chiller – maintains stable low temperatures for sensitive reactions

- Circulating Water Vacuum Pump – enables vacuum filtration and reduces boiling point for efficient evaporation

- Rapid Condensation and Steam Recovery System – quickly cools vapor, increases evaporation and recovery rates, and guides gas upward

- Sealed Circulation System – maintains closed-loop operation to save cooling water and improve recovery efficiency

- One-Button Heating and Cooling Switch – easily switches between heating and cooling modes without oil replacement

- Resource-Efficient Design – reduces waiting time, saves energy and water, and optimizes solvent recovery