Detailed Description

Key Features of Mechanical Stirring High Pressure Lab Reactor

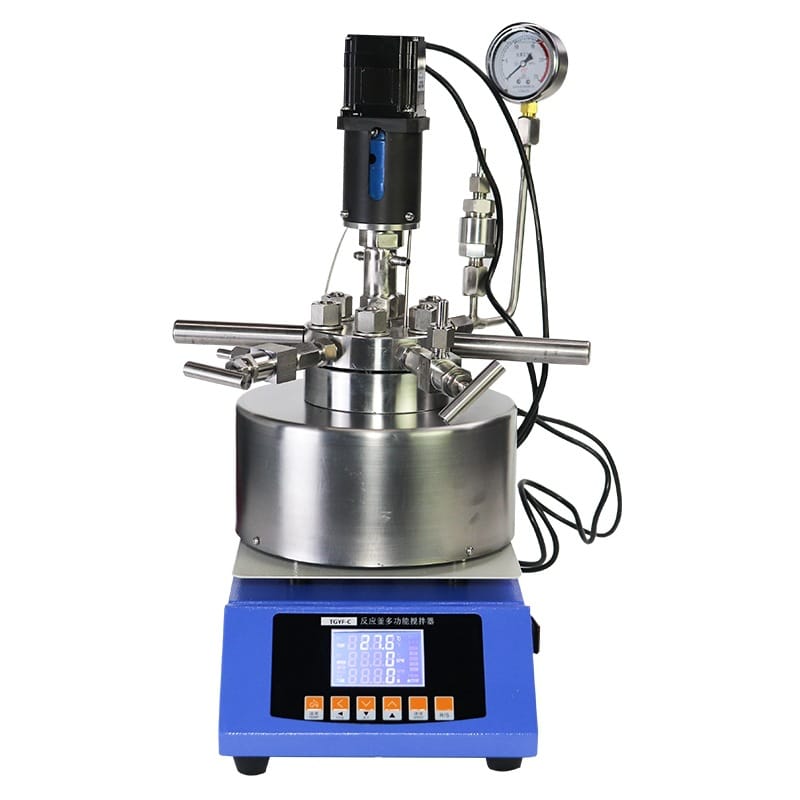

- High Pressure & High Temperature: Operates safely up to 22 MPa and 350°C.

- Mechanical Stirring with Magnetic Coupling: Adjustable 0–1800 rpm, uniform mixing, zero leakage risk.

- PID Temperature Control: Real-time monitoring for repeatable experimental results.

- Modular Electric Heating: Fast and uniform heat transfer.

- Stainless Steel Construction (304/316): Corrosion-resistant and durable.

Available Reactor Volumes (50 ml–500 ml)

50 ml Mechanical Stirring High Pressure Reactor

Designed for catalyst screening and reaction feasibility studies, enabling precise control under high pressure.

100 ml Mechanical Stirring High Pressure Reactor

Suitable for repeatability studies and small-batch synthesis with enhanced sampling capability.

250 ml Mechanical Stirring High Pressure Reactor

Ideal for process development and scale-up evaluation with consistent thermal performance.

500 ml Mechanical Stirring High Pressure Reactor

Provides enhanced capacity for pilot laboratory experiments and extended reaction studies.

Technical Specifications

The TGYF-C Mechanical Stirring High Pressure Lab Reactor offers the following specifications:

- Reactor Volume: 50 ml, 100 ml, 250 ml, 500 ml

- Maximum Pressure: 22 MPa

- Temperature Range: 0°C – 350°C

- Stirring Speed: 0–1800 rpm (adjustable)

- Heating Power: 0.6 kW for 50–250 ml, 0.8 kW for 500 ml

- Heating Method: Modular electric heating

- Stirring Method: Mechanical stirring with magnetic coupling

- Reactor Material: Stainless Steel 304 / 316

- Display: Real-time digital display for temperature, speed, and time

- Sealing Type: Flange sealing

- Power Supply: 220V, 50/60 Hz

Applications of High Pressure Lab Reactor

This mechanical stirring high pressure lab reactor is widely used for chemical synthesis, catalytic reactions, pharmaceutical research, polymerization, hydrogenation, oxidation, hydrothermal, and solvothermal experiments. It is especially suitable for viscous fluids and solid–liquid reaction systems, requiring precise mechanical stirring and controlled reaction conditions.

Compatible Laboratory Equipment

- Precision thermocouples for accurate temperature measurement

- Automated pressure controllers for stable high-pressure operation

- Cooling circulators for temperature regulation

- External filtration systems for post-reaction separation

Why Choose Our Mechanical Stirring High Pressure Lab Reactor

- Single-focus design optimized for high pressure lab experiments

- High torque mechanical stirring with magnetic coupling for safety

- Precise PID control for temperature and stirring speed

- Compact design with industrial-grade performance

- Customizable configurations for specific process requirements

Direct factory manufacturing with technical consultation, customization, and reliable after-sales support.

Frequently Asked Questions

What is a mechanical stirring high pressure lab reactor? A laboratory pressure vessel with motor-driven stirring, allowing controlled mixing, temperature regulation, and high-pressure operation.

What pressure can this reactor withstand? Up to 22 MPa, suitable for most laboratory-scale high pressure reactions.

Is magnetic coupling stirring safe for high pressure reactions? Yes, it eliminates direct shaft penetration, reducing leakage risks and improving safety.

How do I choose the correct reactor volume for my experiment? Depends on batch size, material viscosity, and reaction requirements. Smaller volumes for screening, larger volumes for scale-up and extended studies.

Can the mechanical stirring high pressure reactor be customized? Yes. Material, volume, heating, and control options can be customized for specific experimental needs. For more details and options, visit our High Pressure Reactor category.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | 50ml | 100ml | 250ml | 500ml |

|---|---|---|---|---|

| Reactor Volume | 50 | 100 | 250 | 500 |

| Pressure Range | Up to 22 MPa | |||

| Temperature Range | 0°C to 350°C | |||

| Stirring Speed | 0-1800 rpm (adjustable) | |||

| Heating Power | 0.6 kW | 0.6 kW | 0.8 kW | 1 |

| Heating Method | Modular electric heating | |||

| Stirring Method | Magnetic coupling stirring | |||

| Material | Stainless Steel 304 or 316 (optional) | |||

introduce

Application Scenarios

Catalyst Screening and Reaction Kinetics Studies

In R&D labs, researchers use the reactor to evaluate catalyst efficiency under high-pressure conditions, ensuring accurate data for kinetic modeling and optimization.Synthesis of Fine Chemicals and Intermediates

Ideal for synthesizing high-purity organic compounds, the system enables precise control over reaction parameters critical to specialty chemical production.Polymerization Processes

Suitable for pressure-driven polymerization reactions such as nylon, polyester, and polyurethane synthesis where controlled stirring and temperature are essential.Hydrothermal and Solvothermal Synthesis

Excellent for creating nanomaterials, metal-organic frameworks (MOFs), and other advanced materials through controlled high-temperature and high-pressure pathways.Pharmaceutical Compound Development

Supports the development of APIs (Active Pharmaceutical Ingredients) and other drug intermediates where reaction consistency, safety, and purity are required.Biomass and Waste Conversion

Applied in the transformation of biomass or plastic waste into value-added chemicals using catalytic high-pressure reactions.

This Mechanical Stirring High-Pressure Reactor is the perfect solution for professionals in academia, pharmaceuticals, petrochemicals, and materials science, delivering precision, safety, and repeatability in every high-pressure experiment.

peculiarity

magnetic coupling system

no-load start。 high pressure resistance。

Pressure Gauge

Real-time Monitoring of Reaction Pressure in the Vessel

Stainless Steel Reactor Lid

Equipped with Inlet Valve, Sampling Valve, Exhaust Valve, Pressure Gauge, and Temperature Probe

Control Panel

Precise control with digital display on the screen, Adjustable temperature and speed.