Detailed Description

Product Overview

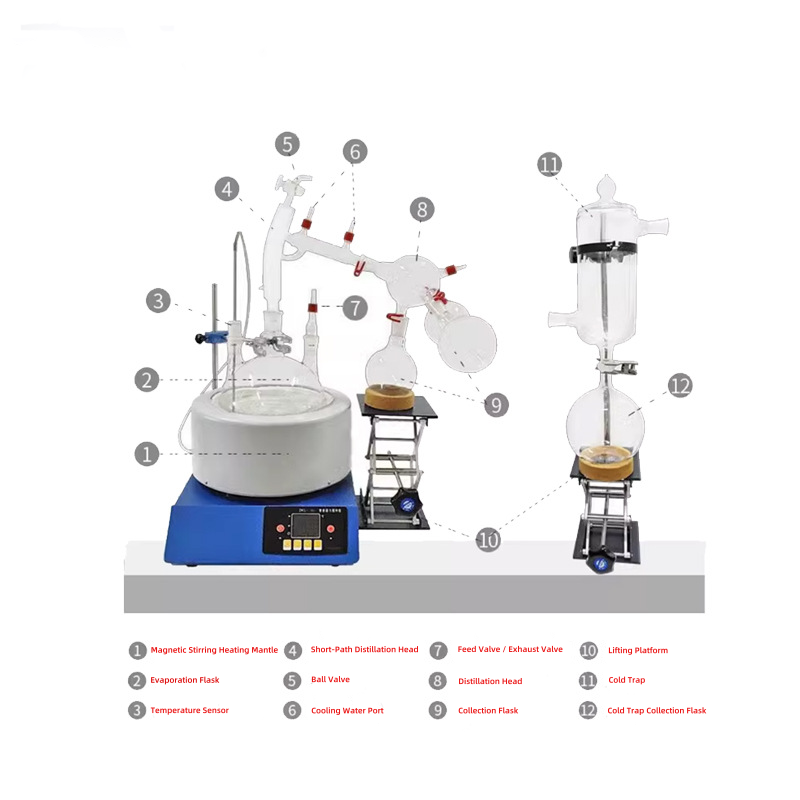

This molecular distillation system is a short-path distillation solution developed for high-boiling and heat-sensitive materials requiring precise separation under vacuum conditions. By minimizing the distance between the evaporation surface and the condenser, the system reduces thermal degradation while improving separation efficiency and product purity.

The modular design allows the system to be configured for different processing volumes, making it suitable for laboratory-scale experiments as well as pilot-scale distillation trials.

Typical Applications

Essential oil purification and concentration

Botanical and plant extract processing

Separation of heat-sensitive and high-boiling compounds

Laboratory research and formulation development

Pilot-scale molecular distillation validation

Key Features

Wide capacity range (500 mL–20 L)

Supports small laboratory testing and pilot-scale processing with flexible configuration options.Electric heating mantle with integrated stirring

Heating power from 200 W to 3000 W and stirring power of 40 W ensure uniform heat transfer and stable operation.Precise temperature and speed control

Adjustable stirring speeds from 50 to 1800 r/min and temperature range from ambient to 380 °C enable accurate process control.High-quality glass distillation components

Three-neck distillation flasks, short-path distillation heads, temperature sleeves, and glass vapor/air baths provide excellent chemical resistance and visual observation.Multiple collection options

Collection bottles from 100 mL to 2000 mL allow efficient fraction recovery and process flexibility.Enhanced operational safety

Detachable connectors, plastic clamps, lifting platform, and reinforced support structures help secure glassware during operation.Expandable system configuration

Optional low-temperature equipment (–120 °C to RT) and vacuum systems enhance condensation and separation performance.

Capacity Options

Available configurations include:

500–2000 mL

5000 mL

10 L

20 L

Each capacity is designed to maintain stable evaporation and condensation performance across different processing scales.

Technical Specifications (Overview)

Heating power: 200 W–650 W (small volumes), up to 3000 W (20 L)

Stirring power: 40 W

Stirring speed range: 50–1800 r/min

Operating temperature range: Ambient to 380 °C

Distillation flasks: Three-neck design with 24/39 joints

Collection vessels: 100 mL, 250 mL, 500 mL, 1000 mL, 2000 mL

Integrated safety components and cold trap for vacuum pump protection

Compatible Equipment

To achieve optimal performance, the system can be combined with:

Vacuum pumps – Circulating water or diaphragm pumps for stable vacuum conditions

Cooling systems – External chillers or cold traps for improved condensation efficiency

Auxiliary stirring systems – Overhead or magnetic stirrers for uniform film formation

Heating baths – Oil or water baths for temperature stability when processing viscous materials

Key Advantages

Gentle separation suitable for heat-sensitive materials

Flexible configuration from laboratory to pilot scale

High purity and reproducible distillation results

Modular design for future upgrades and expansion

Safe and stable operation with clear visual monitoring

Product Demonstration

Watch our product demonstration videos on YouTube to see real-world applications of our short-path molecular distillation system in laboratory and pilot-scale setups. Learn operating procedures, setup tips, and performance results to help you achieve high-purity essential oils and botanical extracts in your own experiments.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Item | 500–2000ml | 5000ml | 10L | 20L | Quantity |

|---|---|---|---|---|---|

| Electric Heating Mantle |

Heating Power: 200W–650W Stirring Power: 40W Stirring Speed: 50–1800 r/min Temperature Range: RT–380℃ Capacity: 500–2000ml / 5000ml / 10L / 20L | ||||

| Three-neck Distillation Flask | 500–2000ml | 5000ml | 10L | 20L | 1 pc |

| Temperature Sleeve | 24/39 | 1 pc | |||

| Short-neck Distillation Head | 24/39 | 1 pc | |||

| Short-neck Ball Joint | 24/39 | 1 pc | |||

| Glass Vapor/Air Bath | 24/39 | 1 pc | |||

| Cow Horn Head | 500ml, 24/39 | 1 pcs | |||

| Collection Bottles | 100/250ml | 500ml | 1000ml | 2000ml | 3 pcs |

| Connectors | Detachable 3/8"(Φ10mm) rubber hose, max sealing safety | 3 pcs | |||

| Plastic Clamps | Enhance sealing safety | 6 pcs | |||

| Lifting Platform | 1 pc | ||||

| Support / Motor Rings | Secure round-bottom and spherical flasks | 3 pcs | |||

| Finger Clamps | Fixation components | 3 pcs | |||

| Cold Trap | Protect vacuum pump from vapor contamination and glass | 1 pc | |||

| Optional Equipment | Low-temperature device -120℃–RT, Circulating water vacuum pump | x | |||

introduce

Application Scenarios

The Molecular Distillation system is ideal for laboratories and pilot-scale production where high-purity separation is required. It is widely used in the Molecular Distillation of plant extracts, essential oils, and thermally sensitive compounds. Typical applications include:

Essential Oil Purification: Efficient separation and concentration of delicate plant essential oils without degradation.

Cannabis Extract Refinement: High-purity THC and CBD isolation from cannabis oils using Molecular Distillation technology.

Pharmaceutical Intermediates: Purification of heat-sensitive pharmaceutical liquids and intermediates with precise temperature control.

Food & Beverage Industry: Extraction of flavors, fragrances, and functional compounds from natural sources.

Chemical Research: Laboratory-scale Molecular Distillation for solvent recovery, specialty chemical purification, and experimental studies.

This Molecular Distillation equipment provides gentle and precise separation at the molecular level, ensuring maximum yield and high-quality purified products for various industries.

peculiarity

Compatible Equipment

Vacuum Pump – Ensures efficient vapor removal and lowers boiling points for high-purity Molecular Distillation.

Chiller / Cooling Circulator – Provides stable cooling for the condenser and cold trap, protecting the vacuum pump.

Magnetic Stirring Heating Mantle – Offers controlled heating and uniform stirring of the distillation flask.

Lifting Platform – Adjusts the height of the reactor or flask for safe and convenient operation.

Collection Flask Set – Collects distilled fractions efficiently and safely.

Cold Trap Collection Flask – Captures condensable vapors from the cold trap to prevent pump contamination.

Temperature Sensor / Controller – Monitors and maintains precise temperature for sensitive compounds.

Optional Low-Temperature Device – Allows Molecular Distillation under ultra-low temperature conditions (-120℃–RT).