Detailed Description

Key Features of Stainless Steel Hydrothermal Synthesis Reactor

Wide range of inner capacities from 5ml to 500ml to suit various reaction scales

Durable 304 stainless steel body offering excellent structural strength and corrosion resistance

Chemically resistant PTFE liner ensures contamination-free reactions and easy cleaning

Secure screw cap seal with manual clamping for reliable pressure containment and leak prevention

Safe operation at temperatures up to 220°C and pressures up to 3 MPa

Certain models equipped with booster lever for enhanced sealing pressure and additional safety

Suitable for a variety of hydrothermal synthesis applications in research and industry

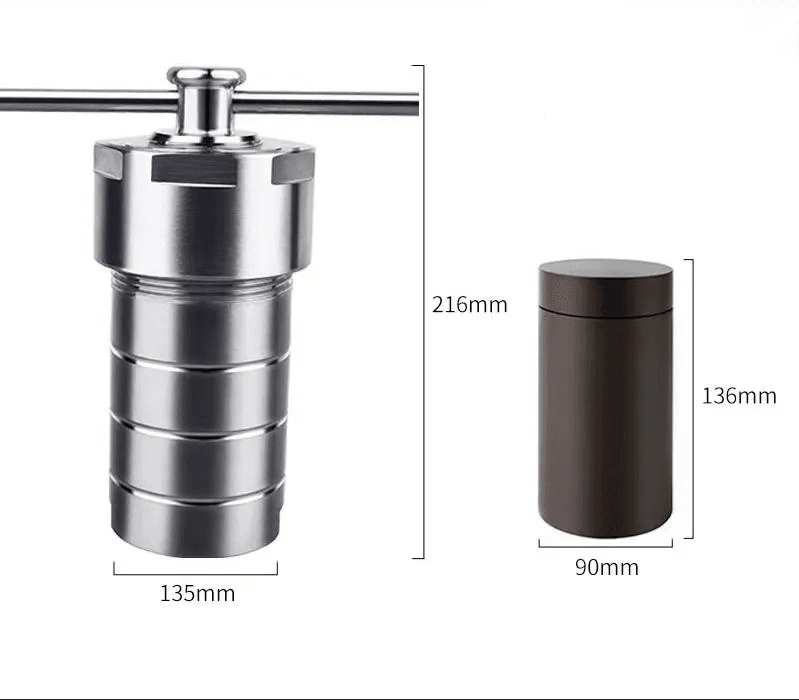

Technical Specifications

Model Range: AKHC-5, AKHC-10, AKHC-15, AKHC-20, AKHC-50, AKHC-100, AKHC-150, AKHC-200, AKHC-250, AKHC-300, AKHC-400, AKHC-500

Inner Capacity (ml): 5, 10, 15, 20, 50, 100, 150, 200, 250, 300, 400, 500

Body Material: 304 Stainless Steel

Liner Material: PTFE (Polytetrafluoroethylene)

Booster Lever: None or 8*200 (depending on model)

Sealing Method: Screw Cap Seal with Manual Clamping

Maximum Temperature: ≤ 220°C

Maximum Pressure: ≤ 3 MPa

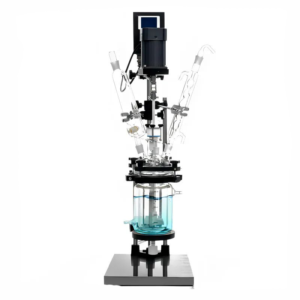

Compatible Laboratory Equipment

This stainless steel hydrothermal synthesis reactor can be paired with a variety of lab equipment such as temperature controllers, heating mantles, safety valves, and reaction monitoring systems. It is ideal for applications in chemical synthesis, material science research, pharmaceutical development, and other fields requiring controlled hydrothermal conditions.

Why Our Stainless Steel Hydrothermal Synthesis Reactor Stands Out

The reactor’s robust construction and superior sealing design ensure safe and consistent performance during hydrothermal reactions. The combination of stainless steel and PTFE materials provides excellent durability and chemical resistance. Its wide capacity range and reliable pressure containment make it a versatile and essential tool for both research and industrial laboratories.

Watch Product Demonstrations

Explore real-world performance and applications in our product demo videos. Visit our video library for more insights and demonstrations.

Discover More in Our Hydrothermal Synthesis Autoclave Collection

For additional models and configurations, visit our hydrothermal synthesis autoclave category and find the ideal reactor tailored to your specific laboratory needs.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKHC-5 | AKHC-10 | AKHC-15 | AKHC-20 | AKHC-50 | AKHC-100 | AKHC-150 | AKHC-200 | AKHC-250 | AKHC-300 | AKHC-400 | AKHC-500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inner Capacity (ml) | 5 | 10 | 15 | 20 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 500 |

| Body Material | 304 Stainless Steel | |||||||||||

| Liner Material | PTFE (Polytetrafluoroethylene) | |||||||||||

| booster lever | None | 8*200 | ||||||||||

| Sealing Method | Screw Cap Seal with Manual Clamping | |||||||||||

| Max Temperature | ≦220℃ | |||||||||||

| Max Pressure | ≦3Mpa | |||||||||||

introduce

Application Scenarios

Nanomaterials Synthesis – Enables precise formation of nanoparticles under controlled hydrothermal conditions

Advanced Ceramics Production – Suitable for fabricating fine ceramics with uniform structure and high thermal stability

Crystal Growth Experiments – Ideal for growing single crystals in laboratory research settings

Solvothermal and Hydrothermal Reactions – Supports diverse chemical reactions requiring elevated temperature and pressure

Catalytic Reaction Studies – Compatible with high-pressure catalyst testing and reaction kinetics research

Material Structure Modification – Used in developing and altering material properties for R&D projects

Academic and Industrial Research – Widely used in universities, chemical labs, and industrial development centers

Organic Synthesis Applications – Suitable for reactions involving corrosive chemicals and solvents

peculiarity

Customizable

Available in various specifications, with customization options to meet customer requirements.

PTFE Liner

Corrosion-resistant, anti-contamination, easy to clean, high-temperature resistant, and long-lasting.

Thickened Stainless Steel Reactor Body

Made from 304 stainless steel with threaded sealing, corrosion resistance, high pressure tolerance, and anti-explosion design, ensuring high safety.

Superior Sealing Performance

Features circular tongue-and-groove sealing for strong leak prevention, ensuring reliable and secure use.