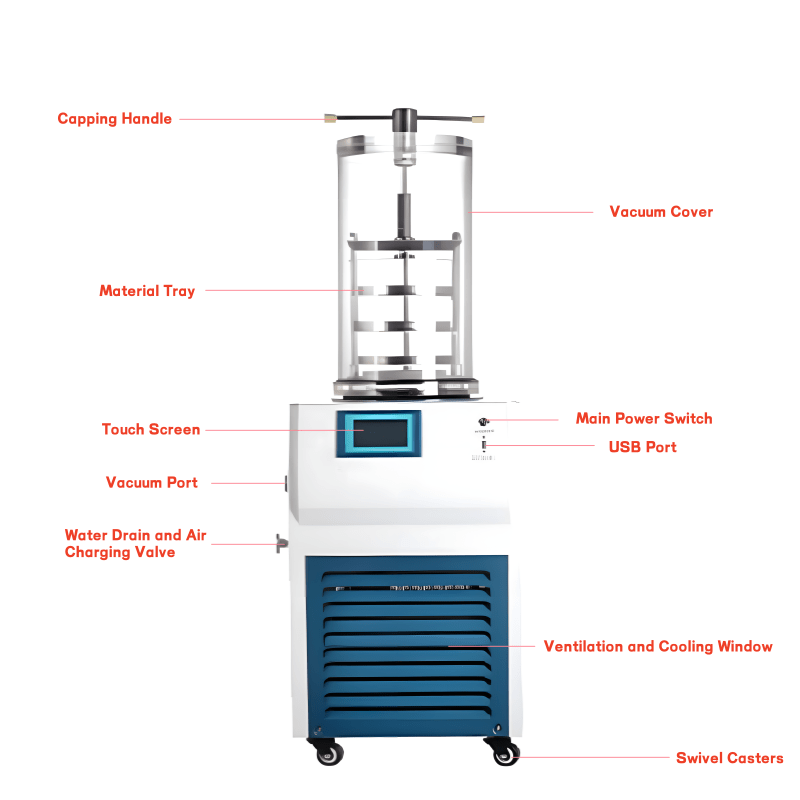

Detailed Description

Key Features of Top Press Freeze Dryer

- Top press design for uniform vial-based freeze drying

- Ultra-low temperature cold trap: ≤ -55°C (optional ≤ -80°C)

- Ultimate vacuum below 5 Pa for efficient sublimation

- Quiet, air-cooled system suitable for standard labs

- Lightweight and compact for space-limited setups

- Intuitive controls for precise process management

Technical Specifications

- Freezing Area: 0.08 m²

- Cold Plate Temperature: ≤ -55°C (optional ≤ -80°C)

- Ultimate Vacuum: ≤ 5 Pa (unloaded)

- Pumping Speed: 2 L/s

- Water Capture Capacity: 3–4 kg / 24 h

- Cooling Method: Air cooling

- Defrost Mode: Natural defrost

- Total Power: 950 W

- Main Unit Weight: 63 kg

- Main Unit Dimensions: 600 × 480 × 770 mm

Vial Capacity & Applications

- φ12 mm vials: up to 920 pcs

- φ16 mm vials: up to 480 pcs

- φ22 mm vials: up to 260 pcs

- Trays: 3 × φ180 mm with max 70 mm press-fit spacing

Supports pharmaceutical, biological, and diagnostic sample processing with excellent batch uniformity.

Laboratory Lyophilization Accessories

- High-performance vacuum pumps (≥ 2 L/s)

- Nitrogen purge systems for sensitive samples

- Vial heat sealing machines for post-drying containment

- Temperature and moisture analyzers for endpoint verification

- Data loggers or freeze-drying monitors for batch documentation and QA compliance

Why Choose EquilRxnLab as Your Freeze Dryer Manufacturer

EquilRxnLab is a trusted laboratory freeze dryer manufacturer and vacuum freeze dryer supplier, providing customized laboratory freeze dryer solutions and OEM freeze dryer options. Our cost-effective freeze dryers are engineered for reliability, efficiency, and consistent performance, making them ideal for research labs, academic institutions, and pilot-scale production.

Why Choose AKGJ-12 Freeze Dryer

The AKGJ-12 delivers an optimal balance of capacity, precision, and usability. Its compact design, high vial throughput, and stable operating parameters make it an excellent choice for small-batch R&D, formulation trials, and laboratory lyophilization projects.

Principles of Freeze Drying

Freeze drying (lyophilization) is a dehydration process for temperature-sensitive materials. It involves three stages: freezing the sample, primary drying (sublimation) under vacuum to remove most water, and secondary drying (desorption) to remove residual moisture while preserving structure and bioactivity. For more details, see ScienceDirect Freeze Dryers. The AKGJ-12 precisely controls temperature and vacuum to ensure consistent, high-quality vial-based freeze drying.

Explore More Laboratory Freeze Dryers

Looking for different capacities or configurations? Explore these additional AKGJ series laboratory freeze dryer models:

- Multi Manifolds Model Vacuum Freeze Dryer

- AKGJ-12 Multi-Manifold Press Fit Freeze Dryer

- AKGJ-12 Vertical Standard Vacuum Freeze Dryer Or visit our Vacuum Freeze Dryer category page for more options.

Shipping Information

We provide worldwide shipping for all laboratory equipment. Every order is carefully packaged to ensure safe delivery. If the item is in stock, it will be shipped within 3–7 business days after payment confirmation. For out-of-stock items, we will inform you of the estimated shipping time based on the specific product.

Shipping Methods: DHL, FedEx, UPS, or sea freight (depending on order size and destination)

Estimated Delivery Time:

Asia: 5–10 business days

Europe & North America: 7–12 business days

South America & Africa: 10–15 business days

Sea freight: subject to actual transit time

Tracking: A tracking number will be provided via email once the shipment has been dispatched.

Customs & Duties: Buyers are responsible for any import taxes or customs duties required by their country or region.

For bulk orders, custom packaging, or special shipping arrangements, please contact our team for personalized assistance at lab@equilrxnlab.com.

Product specifications

| Parameter | AKGJ-12 Standard Model | AKGJ-12 Multi-branch Model | AKGJ-12 Press-fit Model | AKGJ-12 Multi-branch Press-fit Model |

|---|---|---|---|---|

| Freezing Area | 0.12m² | 0.12m² | 0.08m² | 0.08m² |

| Cold Plate Temperature | ≤ -55°C (unloaded), optional -80°C (unloaded) | |||

| Ultimate Vacuum | Below 5Pa (unloaded) | |||

| Pumping Speed | 2L/S | |||

| Water Extraction Capacity | 3-4kg/24h | |||

| Cooling Method | Air cooling | |||

| Defrost Mode | Natural defrost | |||

| Main Unit Weight | 63kg | |||

| Main Unit Dimensions | 600×480×770(mm) | |||

| Total Power | 950W | |||

| Sample Trays | 4 trays, φ200mm, spacing 70mm | 4 trays, φ200mm, spacing 70mm | 3 trays, φ180mm, max press-fit spacing 70mm | 3 trays, φ180mm, max press-fit spacing 70mm |

| Flasks | none | 8 flasks: 100ml, 150ml, 250ml, 500ml (2 each) | none | 8 flasks: 100ml, 150ml, 250ml, 500ml (2 each) |

| Vial Support Capacity | φ12mm: 920 vials, φ16mm: 480 vials, φ22mm: 260 vials | φ12mm: 560 vials, φ16mm: 285 vials, φ22mm: 165 vials | ||

| Operating Environment | 10°C~30°C, ≤70% humidity | |||

| Power Supply | Single-phase 220V±10% 50Hz | |||

| Operating Environment Notes | Free of conductive dust, explosive gases, and strong electromagnetic interference | |||

| Storage Temperature | -40°C~50°C | |||

introduce

Application Scenarios

The Top Press Model Vacuum Freeze Dryer is engineered to serve various laboratory and industrial environments where compact design and reliable drying performance are essential. Typical application scenarios include:

Pharmaceutical Laboratories

Ideal for freeze-drying small-batch drugs, vaccines, and bioactive compounds.

Maintains product stability and extends shelf life through precise vacuum control.

Biological & Biomedical Research

Preserves tissues, enzymes, and microbial cultures with minimal structural loss.

Suitable for long-term storage and molecular biology workflows.

Chemical & Material Science Labs

Efficiently removes solvents and moisture from compounds and reaction byproducts.

Enhances sample purity in material synthesis and catalyst preparation.

Food Technology & Nutritional Studies

Supports gentle drying of plant extracts, nutraceuticals, and bioactive ingredients.

Ensures flavor and nutrient retention for analytical testing.

Educational & Institutional Research Settings

Compact size makes it suitable for university and small lab environments.

Provides hands-on training for vacuum freeze-drying processes.

peculiarity

Exclusive Confidential Noise-Canceling Technology

Low decibel / Non-intrusive / Use with confidence

European DANFOSS Compressor

Low noise, high power, long lifespan.

Made with thick copper wire

Low heat generation / Powerful performance / Stable operation

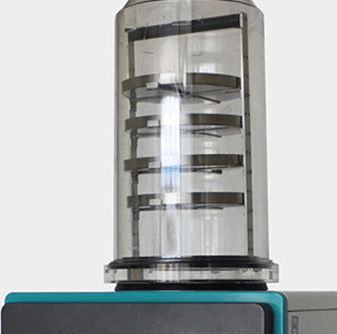

High-Transparency Freeze-Drying Chamber

Scratch-Resistant and Durable / Superior Quality for Long-lasting Use