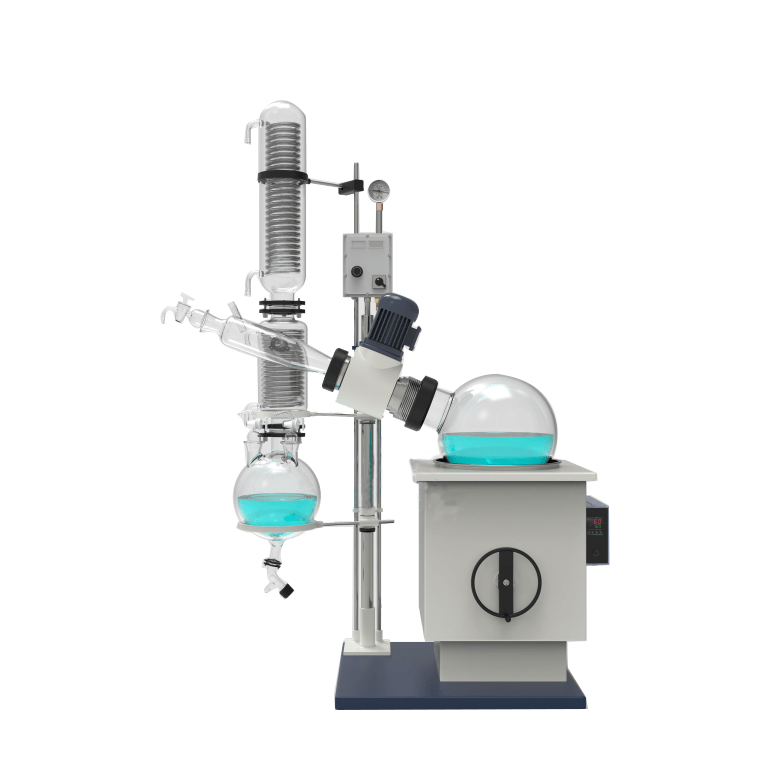

The rotary evaporator is one of the commonly used pieces of equipment in laboratories, widely applied in fields such as chemistry, pharmaceuticals, and biotechnology. Its core function is to evaporate solvents, recover liquids, and concentrate solutions. Proper use of an automatic lifting rotary evaporator not only ensures safety but also significantly improves experimental efficiency. In this article, we will discuss how the correct operation of this equipment can lead to better performance and optimized results.

1. Efficient Solvent Evaporation

Rotary evaporators are designed to handle solvent evaporation efficiently by rotating the flask while applying vacuum and heat. The automatic lifting function adds convenience, as the flask can be raised or lowered with the push of a button, reducing the need for manual adjustments. This precise control allows for faster evaporation rates, improving overall experiment efficiency and reducing the time spent waiting for results.

2. Reducing Human Error

When manually adjusting equipment, there is always a chance for human error. Whether it’s incorrect flask positioning or uneven heating, small mistakes can lead to inconsistent results or even damage to samples. With the automatic lifting feature, the system ensures that the flask is consistently placed in the optimal position for evaporation, minimizing the risk of errors and maintaining the accuracy of the process.

3. Enhancing Safety

Rotary evaporators involve high temperatures and vacuum pressures, which can be hazardous if not handled properly. The automatic lifting system enhances safety by preventing sudden drops or accidents when raising or lowering the flask. In case of an emergency, the automatic lift can quickly move the flask out of the heating bath, ensuring operator safety and protecting sensitive samples.

4. Improving Reproducibility

For experiments requiring precise control over evaporation conditions, reproducibility is key. Automatic lifting rotary evaporators offer consistent and repeatable performance, ensuring that each experiment is conducted under the same conditions. This improves the reliability of experimental results and helps researchers achieve greater accuracy in their findings.

5. Saving Time and Labor

The automation of the lifting process not only saves time but also reduces manual labor. Researchers no longer need to monitor the equipment constantly, as the system can be pre-set to automatically raise the flask when the desired evaporation is complete. This allows the operator to focus on other tasks, improving overall laboratory productivity.

Conclusion

In conclusion, the proper use of an automatic lifting rotary evaporator offers numerous benefits, including increased efficiency, reduced human error, enhanced safety, better reproducibility, and time savings. By utilizing this advanced feature, laboratories can streamline their processes, improve experimental outcomes, and ultimately boost productivity.