In the world of chemical reactions, temperature plays a vital role in determining the speed, efficiency, and outcome of a reaction. Proper reactor chemical reaction temperature control is essential for maintaining optimal conditions throughout the reaction process. Whether you’re working in a laboratory or an industrial setting, maintaining the right temperature is crucial for ensuring consistent results and achieving the desired reaction rates. This article will explore the importance of temperature control in reactors, focusing on how EquilRxnLab reactors are designed to offer precise temperature regulation, ensuring efficient and reproducible chemical reactions.

The Importance of Reactor Chemical Reaction Temperature Control

Reactor chemical reaction temperature control is a fundamental aspect of many chemical processes. Temperature influences several key factors during a chemical reaction:

- Reaction Rate: The rate of most chemical reactions increases with temperature. However, there is a limit to this increase, as very high temperatures can lead to side reactions or the decomposition of reactants.

- Product Yield and Quality: Consistent temperature control ensures that the reaction proceeds under optimal conditions, improving product yield and maintaining high-quality output.

- Catalyst Stability: Many reactions involve catalysts that are sensitive to temperature fluctuations. Maintaining a stable temperature helps preserve catalyst activity, leading to more efficient reactions.

Achieving precise reactor chemical reaction temperature control is essential for maximizing the efficiency and reproducibility of chemical reactions.

How Reactor Temperature Affects Chemical Reactions

Temperature is often a critical parameter in determining the direction and speed of a chemical reaction. The reactor chemical reaction temperature control ensures that the reaction occurs at the correct temperature for optimal efficiency.

- Endothermic Reactions: These reactions absorb heat, and maintaining a stable temperature is essential for providing the energy needed for the reaction to proceed.

- Exothermic Reactions: These reactions release heat, which can cause the temperature to rise uncontrollably if not properly managed. Effective temperature control helps prevent overheating and ensures safety.

- Thermal Decomposition: Many chemical reactions involve the breakdown of compounds through heat. Precise control over the temperature helps prevent the degradation of valuable reactants and ensures the reaction remains efficient.

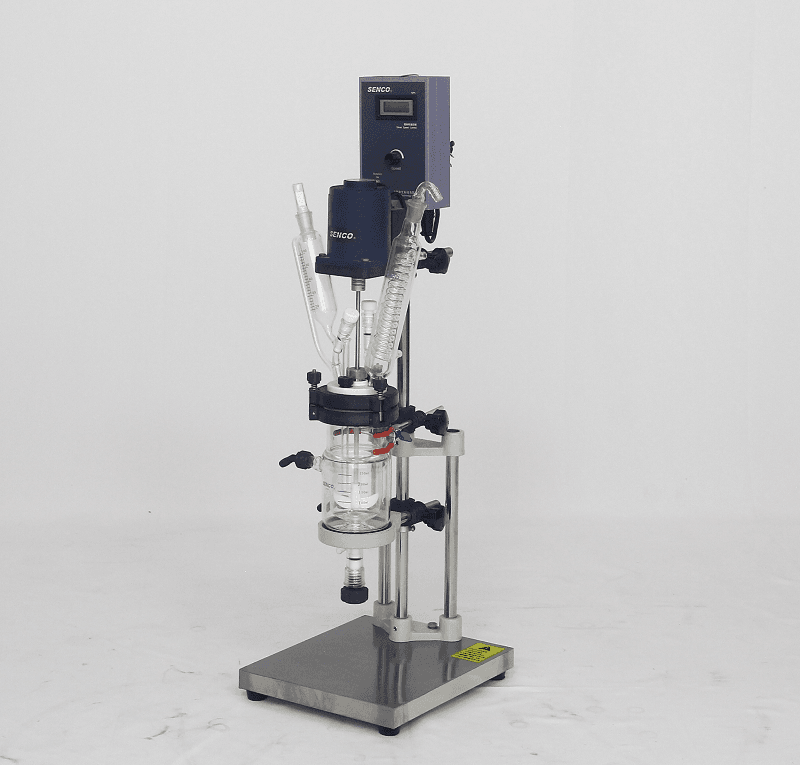

With EquilRxnLab’s innovative reactor systems, achieving precise temperature control is made easier. The 1L double-glazed reactor, for example, is designed with advanced features to maintain the ideal temperature for a variety of chemical reactions.

Key Features of EquilRxnLab Reactors for Temperature Control

EquilRxnLab has engineered its reactors to ensure precise reactor chemical reaction temperature control, offering advanced features that make it ideal for both laboratory and industrial applications:

- Double-Glazed Design: The 1L double-glazed reactor utilizes an insulated double-glazed structure to minimize heat loss, ensuring that temperature fluctuations are minimized throughout the reaction process. This design helps maintain a stable temperature, which is essential for precise control over reaction rates.

- Advanced Heating and Cooling Systems: EquilRxnLab reactors are equipped with advanced heating and cooling systems that enable users to quickly adjust the temperature to meet the specific requirements of their chemical reactions.

- Temperature Sensors and Controllers: The reactors feature high-precision temperature sensors and controllers, allowing users to monitor and maintain the desired temperature with ease.

- Safe and Efficient Operation: The design of the 1L double-glazed reactor ensures safe operation even at high temperatures. Integrated safety mechanisms, such as automatic temperature cutoffs, protect both the user and the system from overheating.

For more details, you can explore the features of the 1L double-glazed reactor on the EquilRxnLab website.

The Impact of Inaccurate Temperature Control in Reactors

Failing to maintain accurate reactor chemical reaction temperature control can have serious consequences for both the reaction and the safety of the system:

- Inconsistent Reactions: Fluctuations in temperature can cause uneven reaction rates, leading to inconsistent product yields and lower overall reaction efficiency.

- Safety Risks: For reactions that are exothermic or involve volatile compounds, improper temperature control can lead to hazardous situations, such as runaway reactions or explosions.

- Degradation of Materials: High temperatures can degrade sensitive materials, including catalysts, reactants, and even the reactor itself, leading to increased costs and wasted resources.

By using EquilRxnLab’s reactors, users can avoid these issues, as the 1L double-glazed reactor provides precise temperature control to ensure that reactions proceed safely and efficiently.

Optimizing Reactor Temperature Control for Different Types of Reactions

Different chemical reactions have varying temperature requirements. The ideal reactor chemical reaction temperature control system must be flexible enough to accommodate these needs. Below are examples of how temperature affects specific types of reactions:

- Polymerization Reactions: These reactions often require strict temperature control to maintain consistent polymer chain growth. Fluctuations in temperature can cause irregularities in the polymer structure.

- Synthesis Reactions: Many chemical syntheses require a narrow temperature range to optimize the formation of the desired product. Overheating can result in the formation of side products.

- Catalysis Reactions: In catalytic processes, maintaining a consistent temperature is crucial for maximizing the efficiency of the catalyst. Sudden temperature changes can deactivate the catalyst or alter the reaction kinetics.

By offering reliable and adjustable reactor chemical reaction temperature control, EquilRxnLab reactors allow users to tailor their systems to meet the specific demands of their reactions.

Why Choose EquilRxnLab for Reactor Temperature Control?

When it comes to reactor chemical reaction temperature control, selecting the right equipment is critical for achieving optimal results. EquilRxnLab reactors, such as the 1L double-glazed reactor, are designed with cutting-edge technology to provide precise and reliable temperature regulation. The advanced temperature control features of these reactors ensure that reactions are conducted under the most favorable conditions, whether you’re working with endothermic or exothermic reactions.

Explore more about the 1L double-glazed reactor on the EquilRxnLab website.

Best Practices for Reactor Chemical Reaction Temperature Control

To ensure that your reactions proceed under the ideal conditions, follow these best practices for reactor chemical reaction temperature control:

- Regularly Monitor Temperature: Use real-time temperature sensors to monitor the reactor’s temperature throughout the reaction process. This allows for immediate adjustments if fluctuations occur.

- Calibrate Temperature Control Systems: Periodically calibrate the reactor’s temperature sensors and controllers to ensure accurate readings and consistent performance.

- Choose the Right Heating and Cooling Systems: Select reactors equipped with efficient heating and cooling systems that can handle the specific temperature requirements of your reactions.

By following these best practices, you can ensure optimal reactor chemical reaction temperature control, improving the efficiency and safety of your experiments.

For more information or specific inquiries, visit EquilRxnLab’s contact page.

Stay connected with EquilRxnLab through our social media profiles:

For a comprehensive list of products, visit our product catalog.

This article emphasizes the critical role of reactor chemical reaction temperature control in ensuring the success of chemical reactions. By maintaining a precise and stable temperature, researchers and industrial practitioners can optimize reaction rates, improve product quality, and enhance safety. With EquilRxnLab’s state-of-the-art reactor systems, you can achieve optimal temperature control, ensuring that your reactions are efficient and reproducible.