Rotary evaporation is an indispensable technique in chemical synthesis, renowned for its efficiency in solvent removal and concentration processes. Laboratories worldwide rely on rotary evaporators to streamline workflows, reduce operational costs, and enhance product purity. This article explores the applications, advantages, and best practices of rotary evaporation in chemical synthesis, providing insights into how this technology supports cutting-edge research and industrial production.

Applications of Rotary Evaporation in Chemical Synthesis

- Solvent Removal and Recovery Rotary evaporation excels in removing volatile solvents from reaction mixtures. By employing vacuum technology and controlled heating, the system ensures efficient solvent evaporation at reduced temperatures, minimizing thermal degradation of heat-sensitive compounds. This process is particularly crucial for maintaining product integrity in synthetic chemistry.

- Concentration of Reaction Mixtures After synthesis, rotary evaporation is commonly used to concentrate reaction mixtures. This step prepares the mixture for further analysis or downstream processing, such as crystallization or chromatography, thereby improving overall workflow efficiency.

- Purification and Separation of Compounds Rotary evaporators assist in separating target compounds by selectively removing unwanted solvents or byproducts. This capability is particularly valuable in multi-step synthesis requiring intermediate purification.

Advantages of Rotary Evaporation in Chemical Synthesis

- Enhanced Efficiency: Compared to traditional evaporation methods, rotary evaporation significantly reduces processing time, expediting experimental and production cycles.

- Temperature Control: Integrated precise heating baths allow gentle evaporation, safeguarding heat-sensitive compounds.

- Vacuum Integration: Vacuum pumps lower solvent boiling points, enabling evaporation at lower temperatures and conserving energy.

- Scalability: From benchtop models for academic research to industrial-scale systems, rotary evaporators cater to diverse needs.

Best Practices for Using Rotary Evaporators

- Optimize Vacuum Settings Adjust vacuum pressure to balance solvent evaporation and prevent bumping. Use appropriate condensers to ensure efficient solvent recovery.

- Select the Right Heating Bath Temperature Choose a temperature slightly above the solvent’s boiling point under reduced pressure to achieve optimal evaporation rates.

- Monitor Rotation Speed Proper rotation speed enhances surface area exposure, improving evaporation efficiency and preventing localized overheating.

- Regular Maintenance Clean and inspect glassware, seals, and tubing regularly to ensure consistent performance and prevent contamination.

Innovative Solutions in Rotary Evaporation

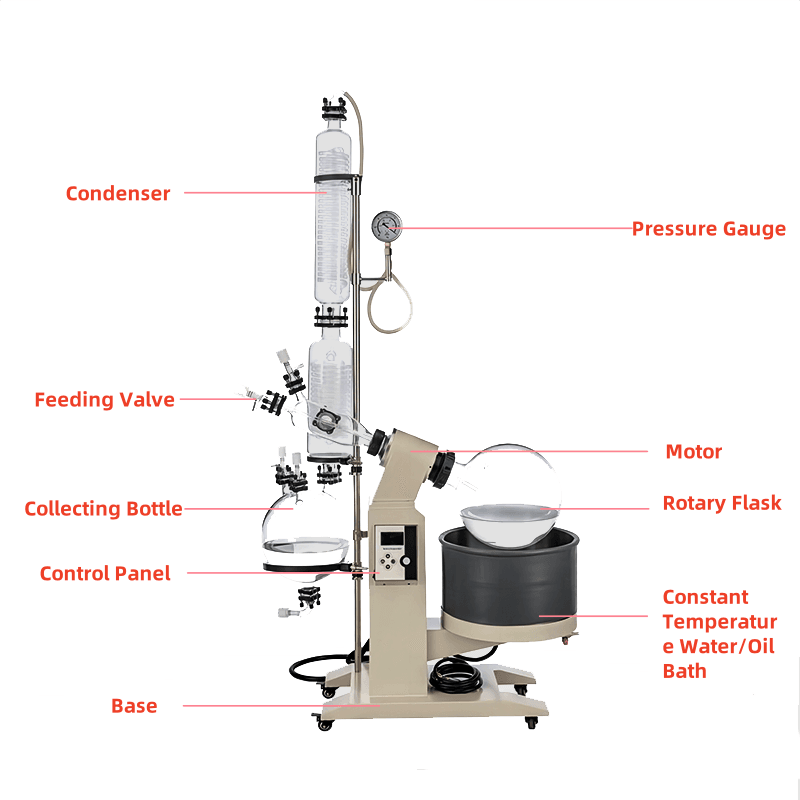

Modern rotary evaporators are equipped with advanced features such as:

- Digital Controls: Precise settings for temperature, rotation speed, and vacuum.

- Automation Systems: Programmed operations to enhance repeatability and efficiency.

- Explosion-Proof Designs: Ensuring safety when handling volatile or hazardous solvents.

Transformative Role of Rotary Evaporation in Chemical Synthesis

Rotary evaporation remains an essential tool in chemical synthesis, bridging the gap between laboratory research and industrial applications. By leveraging its capabilities, scientists can achieve unparalleled efficiency, reproducibility, and product quality.

For laboratories seeking reliable and high-performance rotary evaporators, equilrxnlab offers a range of solutions tailored to diverse synthesis needs. Contact us to learn how our products can optimize your chemical synthesis workflows.

Watch our demonstration on YouTube for more insights into rotary evaporation in action.