The demand for herbal bioactives in transdermal drug delivery systems is growing in both the pharmaceutical and cosmetic industries. These bioactive compounds, derived from plants, offer therapeutic benefits for skin conditions, pain relief, and more. However, extracting and concentrating these delicate compounds without losing their potency requires advanced technology, and one such technique is rotary evaporation.

Rotary Evaporators in Herbal Extract Extraction:

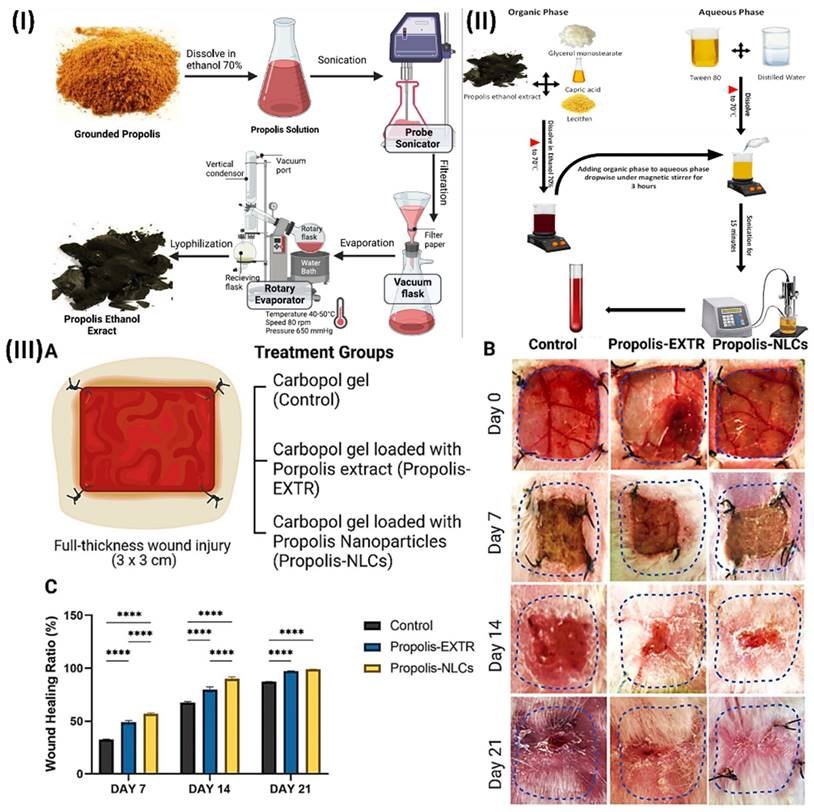

Rotary evaporators are crucial tools for herbal extraction, particularly when preparing bioactives for transdermal drug delivery. The device uses low pressure and gentle heat to remove solvents from plant extracts, ensuring that the active ingredients remain stable and potent. By rotating the solution in a heated bath, rotary evaporation increases the surface area, speeding up the solvent removal process and preserving the integrity of the herbal bioactives.

Ensuring Potent Herbal Bioactives for Skin Care:

Herbal bioactives are sensitive to heat, which is why rotary evaporation is ideal for preserving the therapeutic properties of compounds like curcumin, menthol, and essential oils. This method ensures that these bioactives can be effectively incorporated into transdermal systems such as creams, gels, and patches, offering sustained release and improved skin absorption.

Transdermal Drug Delivery Systems:

The ability to deliver herbal bioactives through the skin offers a non-invasive alternative to traditional oral medications. By using rotary evaporators to extract and concentrate the bioactives, manufacturers can develop high-quality products that ensure consistent dosing and enhanced therapeutic effects. This process is vital for creating products that support pain relief, skin rejuvenation, and other wellness benefits.

Advantages of Rotary Evaporation for Herbal Drug Delivery:

The main advantages of using a rotary evaporator in herbal bioactive extraction for transdermal systems include:

- Efficient Solvent Removal: The rotary evaporation process removes solvents at low temperatures, preventing thermal degradation of sensitive herbal compounds.

- Purity and Concentration: The process increases the concentration of active ingredients, allowing for more potent and effective transdermal formulations.

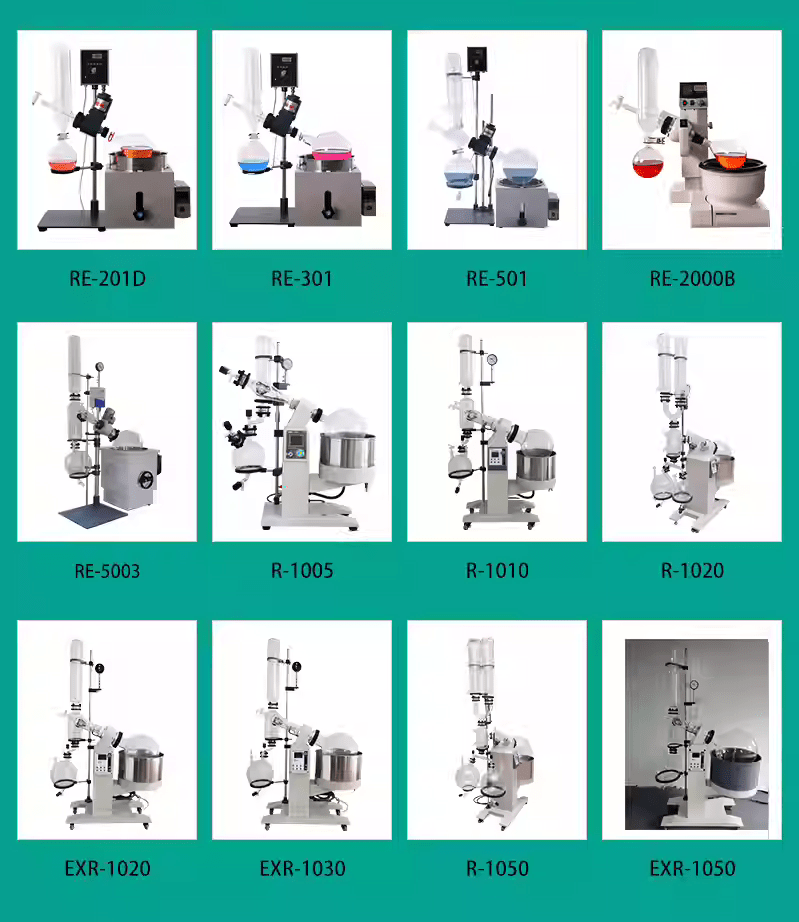

- Scalability: Rotary evaporators can handle both small-scale laboratory extractions and large-scale commercial production, making them a versatile tool in herbal drug delivery.

By using rotary evaporators for herbal bioactive extraction, manufacturers can ensure that the herbal ingredients used in transdermal drug delivery systems remain potent, stable, and effective. This technology not only improves the quality of herbal formulations but also enhances the overall performance of transdermal systems, making it a critical tool in the pharmaceutical and cosmetic industries.

For more information on our Explosion-proof Rotary Evaporator, visit AKRE-1002 Explosion-proof Rotary Evaporator.

For a quick and insightful demonstration of how a rotary evaporator works, check out our YouTube video: Watch the video here.