Introduction to Single Glass Reactor for Pilot Scale Production

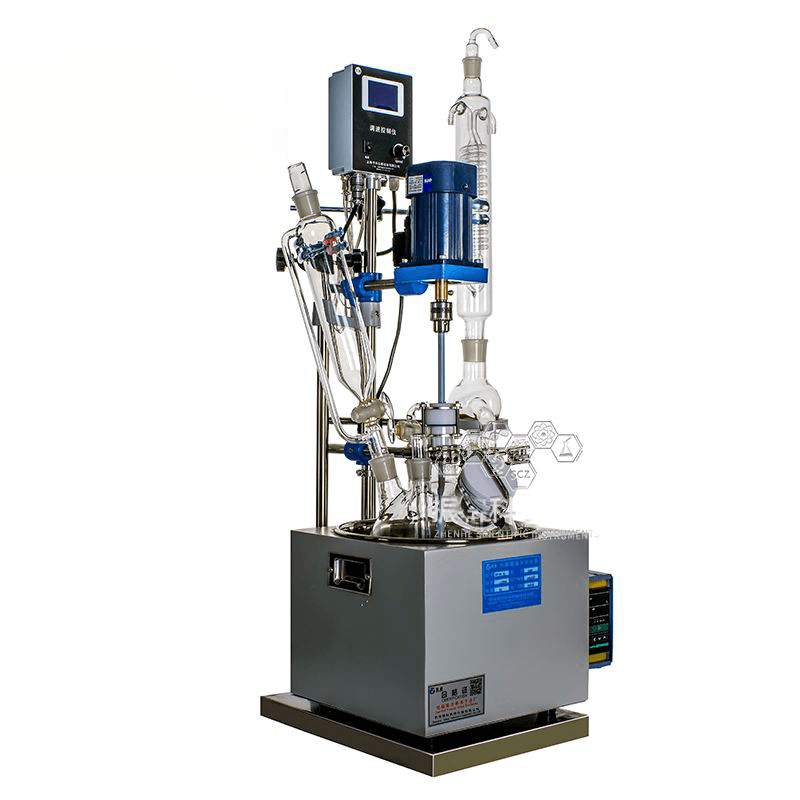

As laboratories progress from small-scale experiments to pilot scale production, the need for specialized equipment that can handle larger volumes becomes crucial. A single glass reactor for pilot scale production offers the necessary features to scale up chemical reactions while maintaining the control and precision needed for research. These reactors are an essential tool in the process of transferring laboratory-scale reactions to a larger scale.

In industries such as pharmaceuticals, chemicals, and biotechnology, the ability to efficiently scale up reactions is fundamental to commercializing products. The single glass reactor for pilot scale production offers a reliable solution, providing accurate control over temperature, pressure, and mixing speeds. This article explores the various features and applications of these reactors, as well as considerations for selecting the right model for your pilot-scale production needs.

Key Features of Single Glass Reactor for Pilot Scale Production

A single glass reactor for pilot scale production is designed to meet the demands of scaling up chemical reactions. Here are some of the key features that make these reactors suitable for larger production processes:

1. High Capacity and Versatility

For pilot scale production, reactors need to have a larger capacity compared to standard laboratory models. A single glass reactor for pilot scale production typically comes in sizes ranging from 5L to 50L or more, allowing for increased volume and better material throughput. Reactors like the AKDF-3L Glass Reactor with Oil Bath are designed with scalability in mind, offering versatility for both small-scale and pilot-scale operations.

2. Precise Temperature Control

Temperature control is critical in scaling up chemical reactions. A single glass reactor for pilot scale production features advanced temperature regulation systems, often including oil baths or water baths, to maintain consistent temperatures. This precision ensures that reactions proceed under optimal conditions, preventing overheating or underheating, which could affect the final product quality.

3. Efficient Mixing and Agitation

Proper mixing is essential for uniform reactions. In larger reactors, ensuring effective agitation can be challenging, especially when dealing with higher viscosities or larger volumes. A single glass reactor for pilot scale production typically includes an efficient stirring system with adjustable speeds, allowing for the control of mixing intensity and ensuring even distribution of reactants.

4. Pressure Control and Safety Features

Many chemical reactions at the pilot scale involve high pressure or volatile compounds. Therefore, a single glass reactor for pilot scale production is equipped with pressure control systems, such as pressure relief valves and vacuum capabilities. These features prevent over-pressurization and ensure that the reactor operates safely throughout the reaction process.

Applications of Single Glass Reactor for Pilot Scale Production

The single glass reactor for pilot scale production serves a wide range of applications in various industries. Here are some of the most common uses:

1. Chemical Synthesis and R&D

In chemical research and development, scaling up reactions from lab scale to pilot scale is essential for testing the feasibility of large-scale production. A single glass reactor for pilot scale production provides the flexibility to conduct experiments that simulate real-world production conditions. Researchers can test reaction conditions and optimize parameters such as temperature, pressure, and mixing to improve the yield and efficiency of chemical processes.

2. Pharmaceuticals and Biotech

In the pharmaceutical and biotechnology industries, single glass reactors are used for the synthesis of active pharmaceutical ingredients (APIs) and the production of biologics. These reactors are particularly useful for producing small batches of compounds for clinical trials or for scaling up manufacturing processes. The precise control over the reaction environment ensures that the quality of the product remains consistent, even at larger production scales.

3. Food and Beverage Processing

The food and beverage industry also benefits from the use of single glass reactors in the production of flavorings, additives, and other chemical compounds. Reactors used in this industry are designed to handle food-grade materials while maintaining high safety and quality standards. The ability to scale up recipes from small laboratory batches to larger production volumes is crucial for the commercial success of many food products.

4. Cosmetics and Personal Care Products

The cosmetics industry uses single glass reactors for the production of lotions, creams, perfumes, and other personal care products. A reactor designed for pilot scale production allows manufacturers to produce small batches for testing before committing to full-scale production. The flexibility of the reactor enables manufacturers to experiment with different formulations and ensure that the final products meet regulatory standards.

How to Choose the Right Single Glass Reactor for Pilot Scale Production

When selecting a single glass reactor for pilot scale production, several factors must be considered:

1. Capacity Requirements

The first consideration is the capacity of the reactor. Pilot-scale reactors typically range from 5L to 50L or more, depending on the scale of the production process. It is essential to choose a reactor with a sufficient capacity to handle the expected reaction volume. For smaller production runs, reactors such as the AKDF-3L Glass Reactor with Oil Bath are an excellent choice.

2. Reactor Features and Customization

Different production processes may require specific features, such as additional heating systems, temperature sensors, or specialized mixing mechanisms. Many suppliers offer customizable options that allow you to configure the reactor to meet your exact needs. Ensure that the supplier provides detailed specifications to help you select the right model.

3. Budget Considerations

Cost is always a consideration when choosing lab equipment. While it’s essential to invest in high-quality reactors, single glass reactors for pilot scale production come in a variety of price ranges. It’s important to strike a balance between affordability and functionality. Look for suppliers that offer competitive pricing without compromising on essential features and performance.

For instance, EquilRxnLab provides affordable options like the AKDF-3L Glass Reactor with Oil Bath, designed for pilot-scale operations, ensuring you get the best value for your investment.

Where to Buy Single Glass Reactors for Pilot Scale Production

When purchasing single glass reactors for pilot scale production, it is crucial to buy from a reliable supplier. A reputable supplier will provide high-quality reactors, detailed product specifications, and excellent customer support.

EquilRxnLab is a trusted supplier of single glass reactors, offering a wide range of models suitable for pilot scale production. Their products, including the AKDF-3L Glass Reactor with Oil Bath, are designed to meet the demands of both research and industrial applications.

For more details on their products, visit EquilRxnLab’s product catalog.