In the realm of chemical engineering and laboratory research, precision is key. The ability to control the temperature and cooling rate during reactions can significantly impact the success and efficiency of experiments. This is where Single Glass Reactor Heating and Cooling Systems come into play. These systems are integral for maintaining an optimal environment for chemical processes, ensuring reactions proceed under stable conditions.

What are Single Glass Reactor Heating and Cooling Systems?

The Single Glass Reactor Heating and Cooling Systems are sophisticated setups that combine both heating and cooling capabilities within a single glass reactor. These systems are designed to maintain precise temperatures during a chemical reaction by integrating external heating elements and cooling devices. The ability to heat and cool the reactor effectively is crucial for various types of chemical reactions, especially those that involve exothermic or endothermic processes.

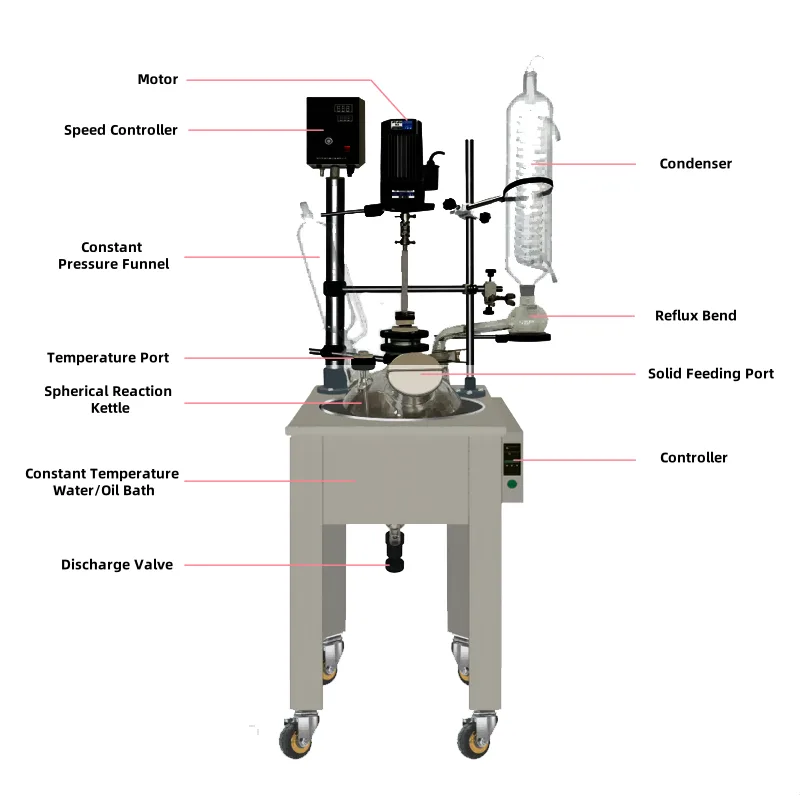

In its basic form, a Single Glass Reactor Heating and Cooling System consists of a glass vessel where the reaction takes place, along with a temperature-regulated heating jacket, and a cooling system to ensure that excess heat is efficiently dissipated. The reactor’s heating system typically uses electric heating mantles or external circulating fluids, while the cooling system often utilizes a cooling jacket or recirculating chiller to maintain lower temperatures when necessary.

Why are Single Glass Reactor Heating and Cooling Systems Important?

Temperature control is one of the most critical factors in determining the outcome of a chemical reaction. If the temperature is too high, it can cause unwanted side reactions or even the decomposition of the target compounds. On the other hand, inadequate heating or cooling can result in slower reaction rates or poor yields. This makes Single Glass Reactor Heating and Cooling Systems indispensable for maintaining reaction conditions that are optimal for success.

Key benefits of these systems include:

- Precise Temperature Control: The primary benefit of a Single Glass Reactor Heating and Cooling System is its ability to precisely control temperature. This is vital for reactions that require exact thermal conditions. For example, chemical reactions that involve volatile solvents or temperature-sensitive materials can benefit from the ability to control heating and cooling cycles effectively.

- Enhanced Safety: By maintaining temperature within a safe range, these systems help prevent overheating or cooling down too rapidly. The integrated cooling system ensures that the reaction mixture does not reach dangerous temperatures, thus preventing accidents such as thermal runaway or the release of hazardous fumes.

- Increased Efficiency: Single Glass Reactor Heating and Cooling Systems allow for more efficient reaction processes by enabling temperature regulation. Consistent temperature management reduces the risk of undesired products and maximizes the yield of the desired reaction. Faster and more efficient reactions also contribute to overall productivity in a laboratory setting.

- Energy Efficiency: The modern Single Glass Reactor Heating and Cooling Systems are designed to be energy-efficient, which helps reduce operational costs over time. With energy-efficient heating and cooling, researchers can achieve optimal reaction conditions without using excessive energy, making these systems more sustainable for long-term use.

Features of a High-Quality Single Glass Reactor Heating and Cooling System

When selecting a Single Glass Reactor Heating and Cooling System, it’s crucial to consider several features to ensure it meets the needs of specific applications. Key features include:

- Durability and Resistance: High-quality borosilicate glass ensures the reactor is resistant to both high temperatures and chemical corrosion. This material is essential for the longevity of the equipment, especially when working with reactive chemicals.

- Temperature Range: The system should be capable of maintaining the required temperature range for a variety of reactions. Whether heating to high temperatures or cooling to sub-zero levels, the reactor should maintain consistent and stable conditions.

- Integrated Heating and Cooling: Some systems combine both heating and cooling elements in one compact design. This integration helps save space and simplifies the setup, providing seamless control over temperature regulation.

- User-Friendly Design: Features such as digital controllers, temperature sensors, and adjustable stirring mechanisms ensure that the system is easy to operate and monitor. This is particularly important when conducting delicate reactions that require close attention to detail.

- Safety Mechanisms: Safety valves and pressure release systems should be incorporated into the design to prevent accidents during high-pressure or high-temperature reactions.

Applications of Single Glass Reactor Heating and Cooling Systems

The versatility of Single Glass Reactor Heating and Cooling Systems makes them suitable for a wide array of applications, ranging from research and development to large-scale industrial processes. Some of the most common applications include:

- Chemical Synthesis: In synthetic chemistry, precise temperature control is essential to achieve high-purity products. These systems allow for the controlled heating or cooling required for complex reactions.

- Pharmaceutical Research: The pharmaceutical industry relies on Single Glass Reactor Heating and Cooling Systems for the production of drugs and active pharmaceutical ingredients. Temperature control ensures the stability of the compounds and the purity of the final product.

- Environmental Studies: Chemical processes related to environmental monitoring and pollutant removal often require strict temperature management. These systems help optimize reaction conditions in research and remediation projects.

- Food and Beverage Industry: The controlled heating and cooling provided by these systems can be used in food extraction and purification processes to ensure that the final products are safe and of high quality.

Choosing the Right Single Glass Reactor Heating and Cooling System

Selecting the right Single Glass Reactor Heating and Cooling System depends on several factors, including the scale of the operation, the type of reaction, and specific temperature requirements. For laboratory-scale reactions, compact models with integrated heating and cooling systems are ideal, while larger industrial applications may require more robust systems with additional features for handling larger volumes and more complex reactions.

For those interested in high-quality and reliable laboratory equipment, EquilRxnLab offers a range of products designed to meet the needs of various industries. Our AKDF 1L Single Layer Glass Reactor features an efficient heating and cooling system, ensuring precise control over your experiments. You can explore more about our product offerings by visiting here.

For video demonstrations and more information about our products, subscribe to our YouTube channel, and follow us on Instagram and Facebook.

If you have any questions or require further assistance, don’t hesitate to contact us.

Single Glass Reactor Heating and Cooling Systems are essential for maintaining the precise thermal control necessary for various chemical processes. Whether you’re conducting research in organic chemistry, pharmaceuticals, or environmental science, these systems ensure that your reactions proceed under optimal conditions. With the right equipment, you can maximize efficiency, improve safety, and achieve consistent results.