Exploring the Various Types of Single Glass Reactors and Their Unique Applications

The development of laboratory equipment has seen a significant evolution in recent years, with a focus on optimizing processes, reducing waste, and improving overall efficiency. One of the most critical tools in modern laboratories is the single glass reactor. Designed for a wide range of applications, the single glass reactor types vary depending on specific requirements such as capacity, reaction type, and operating conditions. Understanding the features and benefits of these reactors can provide laboratories with the tools necessary for achieving precise and reliable results.

What Are Single Glass Reactor Types?

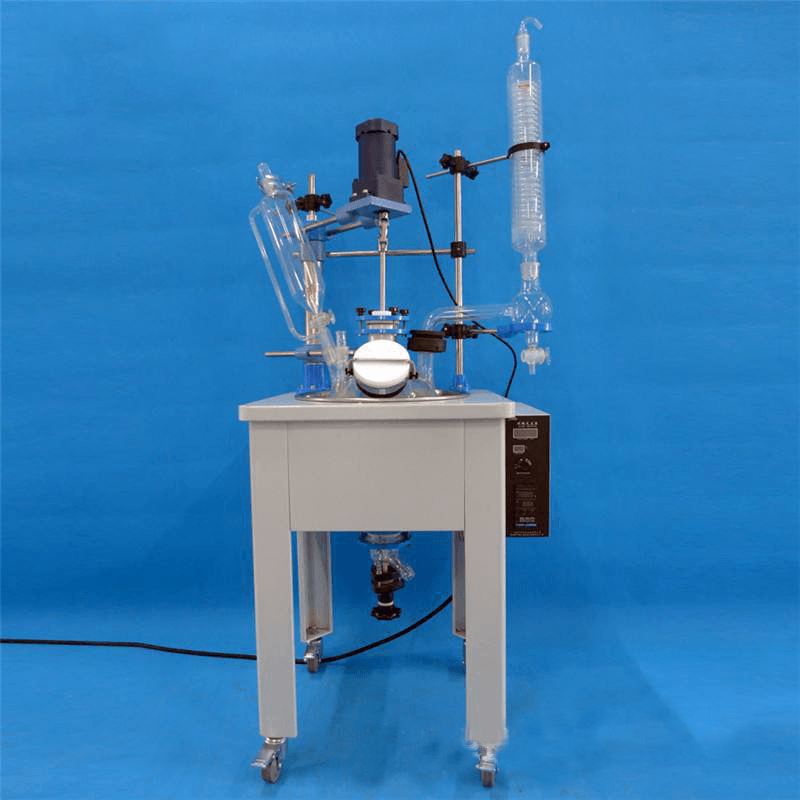

Single glass reactors are specialized laboratory vessels designed to carry out chemical reactions under controlled conditions. They consist of a glass vessel, usually with an agitator and a temperature control system, allowing for a variety of reactions including mixing, heating, and cooling. The single glass reactor types typically differ based on their intended use, such as batch processing or continuous reactions, and their features, such as size, shape, and additional components.

The design of these reactors is essential in achieving accurate and reproducible reactions. By offering precise temperature control, stirring mechanisms, and pressure regulation, these reactors are invaluable in fields such as pharmaceuticals, chemical manufacturing, and food production.

Types of Single Glass Reactors

There are several single glass reactor types that cater to different laboratory needs. Each type has unique advantages that make it suitable for specific applications.

1. Water Bath Single Glass Reactor

The water bath single glass reactor is designed for gentle and controlled heating of substances. This type of reactor uses a water bath surrounding the glass vessel to maintain consistent temperatures. It is often used for reactions that require gradual heating, such as in the synthesis of sensitive compounds or during distillation processes.

One of the advantages of this type of reactor is its ability to provide uniform heating, minimizing the risk of thermal gradients that could lead to uneven reactions. This is particularly important in research applications where consistency is key.

2. Oil Bath Single Glass Reactor

Similar to the water bath reactor, the oil bath single glass reactor is used when higher temperatures are required. The oil bath system allows for more precise temperature control compared to water-based systems, making it suitable for reactions that need to exceed the boiling point of water.

The oil bath single glass reactor is widely used in chemical research and industrial processes where high temperatures are a constant requirement, such as in the synthesis of high-temperature polymers or the production of certain specialty chemicals.

3. Vacuum Single Glass Reactor

The vacuum single glass reactor is designed for reactions that need to be carried out under reduced pressure. This type of reactor is often used in vacuum distillation, degassing, and other processes where removing air or moisture is critical. The vacuum feature helps to lower the boiling point of substances, making it ideal for temperature-sensitive compounds.

Vacuum reactors are commonly employed in the pharmaceutical and food industries for the extraction of volatile compounds or the creation of highly purified substances. The reduced pressure environment ensures that sensitive reactions can proceed without the risk of thermal degradation.

4. Double-Walled Single Glass Reactor

The double-walled design of this single glass reactor provides enhanced insulation and better control over temperature fluctuations. Often used for reactions requiring both heating and cooling, this reactor type is equipped with a jacket that circulates heating or cooling fluid around the glass vessel. The double-walled construction helps maintain a steady reaction temperature and is ideal for processes where precise thermal control is crucial.

This type of reactor is commonly used in laboratories dealing with high-precision chemical synthesis, extraction processes, and other applications that require consistent temperature regulation.

Advantages of Using Single Glass Reactor Types

Each of the single glass reactor types offers distinct advantages, depending on the specific needs of the laboratory. Below are some of the key benefits associated with these reactors:

- Precision in Chemical Reactions: The ability to control temperature, pressure, and stirring speed ensures that reactions can be conducted under optimal conditions. This level of control is essential for achieving accurate and reproducible results, particularly in research and development settings.

- Versatility Across Applications: The various single glass reactor types can be used in a wide range of chemical processes, including synthesis, extraction, distillation, and crystallization. Their adaptability makes them invaluable tools in many industries, from pharmaceuticals to food processing.

- Energy Efficiency: Modern single glass reactor types are designed to be energy-efficient, reducing energy consumption during operations. This is especially important for laboratories aiming to minimize operational costs while maintaining high-performance standards.

- Safety and Reliability: The robust glass construction of these reactors makes them resistant to chemical corrosion and high temperatures. In addition, safety features such as pressure relief valves and secure sealing mechanisms ensure that reactions are conducted safely, minimizing the risks of accidents.

- Sustainability: Some single glass reactor types are designed with environmentally friendly features, such as reduced energy consumption and the ability to minimize waste production. These reactors help laboratories contribute to sustainability goals by promoting green practices in chemical research.

Applications of Single Glass Reactors

Single glass reactor types are used in various industries due to their versatility and ability to conduct precise chemical reactions. Some common applications include:

- Pharmaceuticals: Single glass reactors are used for the synthesis of active pharmaceutical ingredients (APIs), chemical formulations, and compound extraction.

- Chemicals: In chemical production, reactors are employed for polymerization, emulsification, and solvent recovery processes.

- Food and Beverage: These reactors are also used for flavor extraction, fermentation processes, and food ingredient synthesis.

- Biotechnology: Biotechnology labs use single glass reactors for culturing and extracting biological compounds.

Discover the Single Glass Reactor from EquilRxnLab

EquilRxnLab offers a wide range of single glass reactor types, including advanced models designed to meet the rigorous demands of modern laboratories. The AKDF 50L Water Bath and Oil Bath Single-Layer Glass Reactor is a prime example of the high-quality equipment we provide. This reactor is designed for both small-scale and large-scale applications, offering precise control over temperature and pressure conditions.

To learn more about the single glass reactor types offered by EquilRxnLab, visit our product page here. For updates and the latest innovations, follow us on Instagram, Facebook, and YouTube.

The choice of single glass reactor types plays a crucial role in optimizing laboratory processes. By selecting the right reactor for the application at hand, researchers and scientists can improve reaction efficiency, enhance precision, and reduce environmental impact. These reactors are a key part of advancing sustainable practices and achieving successful outcomes in chemical research and production.