Innovative chemical engineering solutions to tackle project challenges, drive innovation, and deliver results.

Committed!

Always deliver more than expected.

We are committed to consistently delivering results that not only meet but surpass expectations, while providing long-term follow-up services to ensure every tailored solution operates smoothly and delivers lasting value.

Hours of Work

Projects Done

Client Satisfaction

Personalization Services

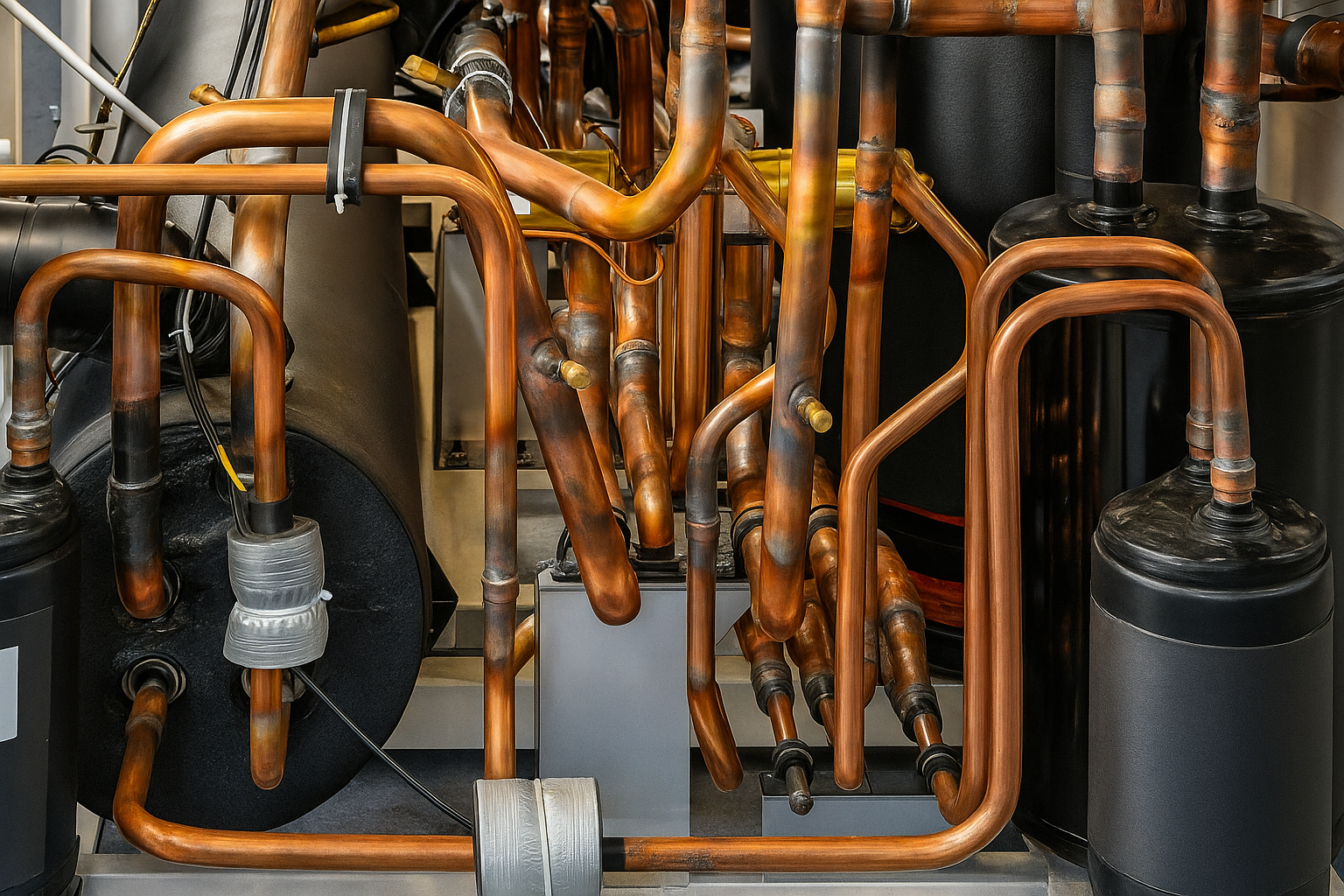

Professional Services

Capacity Customization

Material Customization

Pressure Customization

Temperature Customization

Automation Customization

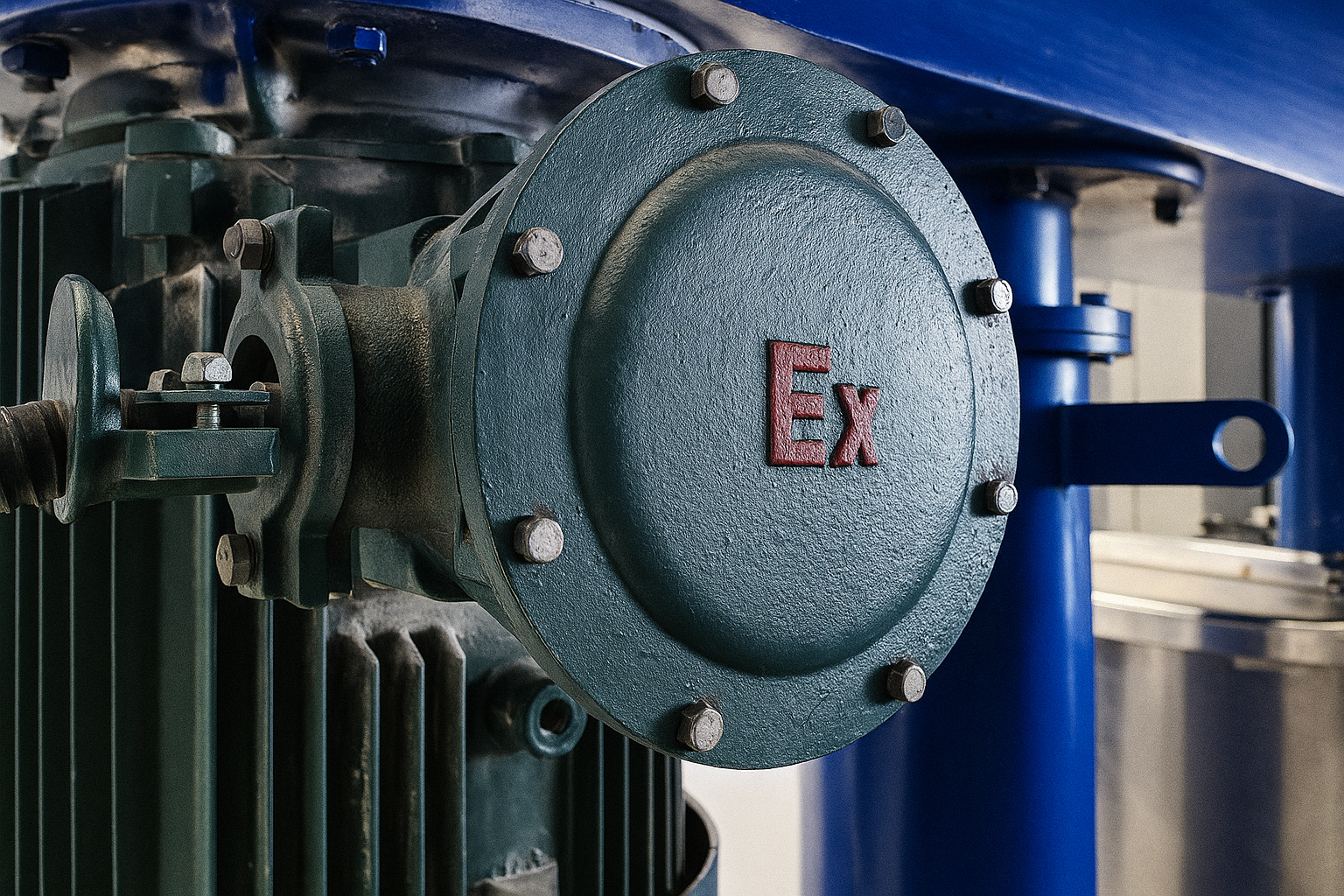

Safety Design Customization

Hear feedback

Testimonial

We’ve been using the customized tail gas treatment system for solvents containing hydrofluoric acid. The unit was built with Hastelloy and a PTFE lining, which so far has shown good resistance to corrosion. After running for some time, the system operates steadily and meets our current needs for exhaust treatment. There are still details we keep monitoring, but overall the solution works as expected for our process.

As a professor in the Chemistry Department, I ordered a customized high-pressure reactor with specific pressure and temperature requirements. The unit was delivered as requested, and after several weeks of use it has been operating steadily and reliably. Both the pressure control and temperature performance meet our expectations, which gives me confidence in using it for our ongoing research and process development.

Our Mechanics

Creative Mechanics

Subscribe For Newsletter

Sign up now for updates about early registration. A wonderful serenity taken possession into entire soul also like.